Viscosity precise control device

A technology of precise control and viscosity, which is applied in the direction of viscosity control, non-electric variable control, control/regulation system, etc. It can solve the problems that solvents affect the sensor effect, are easy to be damaged, and cannot ensure the stable response of ink viscosity for a long time, so as to achieve safe operation and Stable and reliable, simple method and extremely low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

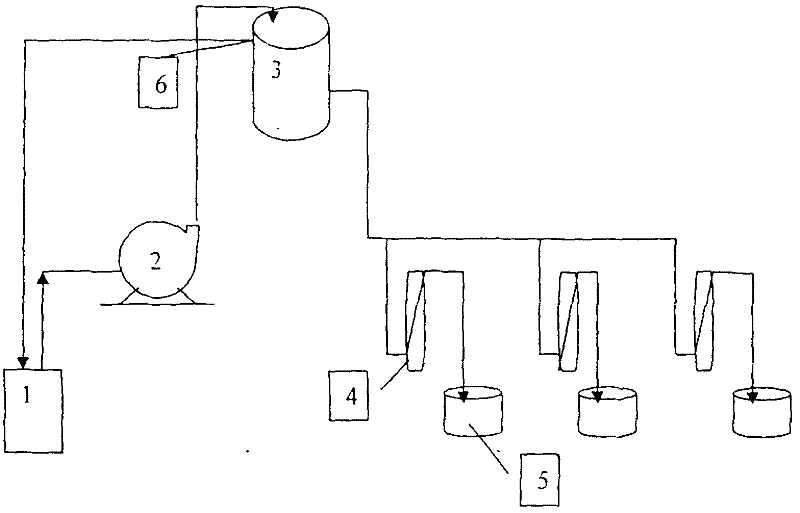

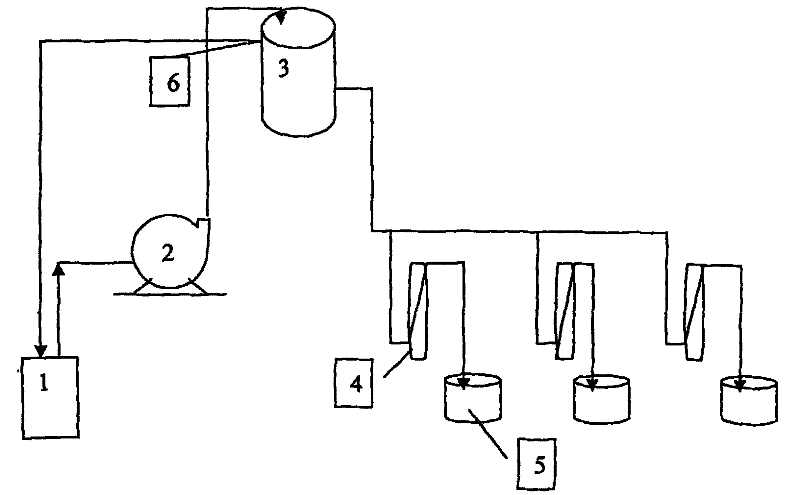

[0008] Viscosity precision control device, including raw material tank 1, solvent delivery pump 2, several flow meters 4 and ink basin 5, the flow meters 4 in front of each ink basin 5 are connected to a high-level storage tank 3 by the same connecting pipe, and the solvent delivery pump The output pipe of 2 is connected with the upper opening of the high-level storage tank 3, and the high-level storage tank 3 is provided with an overflow port 6.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com