Metal runner vertical solar thermoelectric power generation collector

A technology of metal runners and temperature difference power generation, which is applied to solar collectors, solar collectors using working fluids, solar thermal power generation, etc., and can solve problems such as single application, poor practicability, and unreasonable structure of water heaters

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] Embodiment 1 (non-heat pipe form)

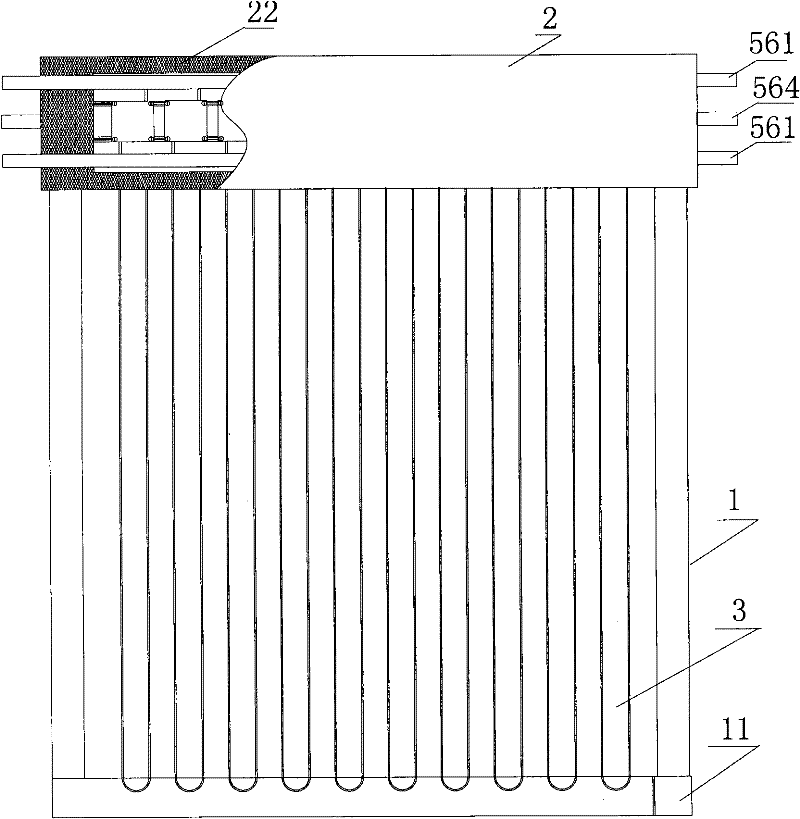

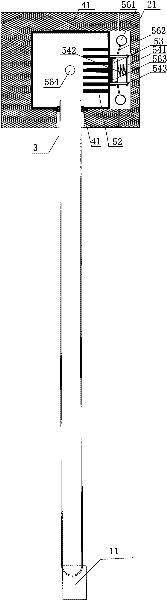

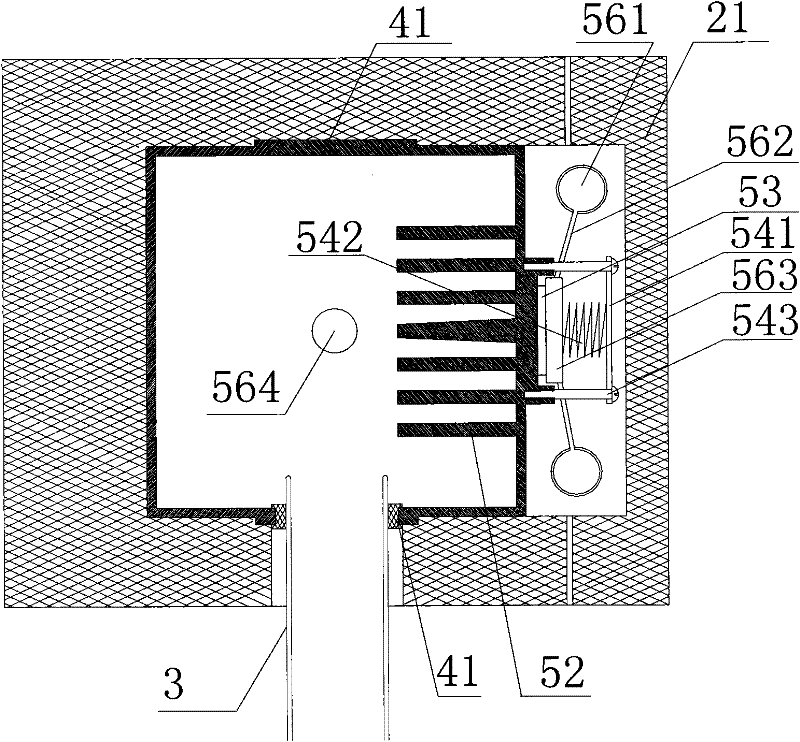

[0027] Such as figure 1 , figure 2 , image 3 As shown, the vertical solar heat collector of this embodiment includes a protective outer box 2, a metal flow channel 4, a number of different or equal diameter glass vacuum tubes 3 and a support 1, and the metal flow channel is placed in the inner cavity of the protective outer box. An insulating layer 22 is filled between the metal runner and the protective outer box. The protective outer box and a number of glass vacuum tubes 3 of different diameters or equal diameters are fixed on the bracket 1. The closed end of the glass vacuum tube is placed at the tail 11 of the bracket. Each glass vacuum tube communicates with the metal flow channel through the through hole, and the interface is airtight. Several power generation module assemblies 5 are installed on the outer wall of the metal flow channel. Each power generation module assembly includes a heat collector 51, a power generation ...

Embodiment 2

[0036] Embodiment 2 (strip solid thermal conductor metal form)

[0037] Such as Figure 4 , Figure 5 As shown, the overall structure of the vertical solar thermoelectric power generation heat collector of this embodiment is similar to the vertical structure of the embodiment, and also includes a protective outer box 2, a metal flow channel 4, a number of glass vacuum tubes 3 with different diameters or equal diameters, and supports 1. The metal flow channel 4 is placed in the inner cavity of the protective outer box 2, and the space between the metal flow channel 4 and the protective outer box 2 is filled with an insulating layer 22, and the protective outer box 2 and a number of glass vacuum tubes 3 with different diameters or equal diameters are fixed on the bracket 1 , the closed end of the glass vacuum tube is placed at the tail of the bracket 11, and the bottom of the protective outer box is provided with a through hole, and a number of thermoelectric power generation a...

Embodiment 3

[0050] Embodiment 3 (combined heat pipe form)

[0051] Such as Figure 6 , Figure 7 As shown, the structure of the vertical solar thermoelectric power generation heat collector in this embodiment is similar to that of Embodiment 2, and also includes a protective outer box 2, a metal flow channel 4, a number of glass vacuum tubes 3 with different diameters or equal diameters, and a bracket 1, and the metal flow channel Placed in the inner cavity of the protective outer box, the metal flow channel and the protective outer box are filled with an insulating layer 22, the protective outer box and a number of glass vacuum tubes with different diameters or equal diameters are fixed on the bracket 1, and the closed end of the glass vacuum tube is placed at the tail of the bracket 11, The bottom of the protective outer box is provided with a through hole, and a plurality of power generation module assemblies 5 are installed through the metal runner at the through hole. Each power ge...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com