Double-wing solar thermoelectric generation collector with metal runner

A metal runner and temperature difference power generation technology, which is applied in solar collectors, solar collectors using working fluids, solar thermal power generation, etc., can solve problems such as unreasonable structure of water heaters, low power generation efficiency, and single application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

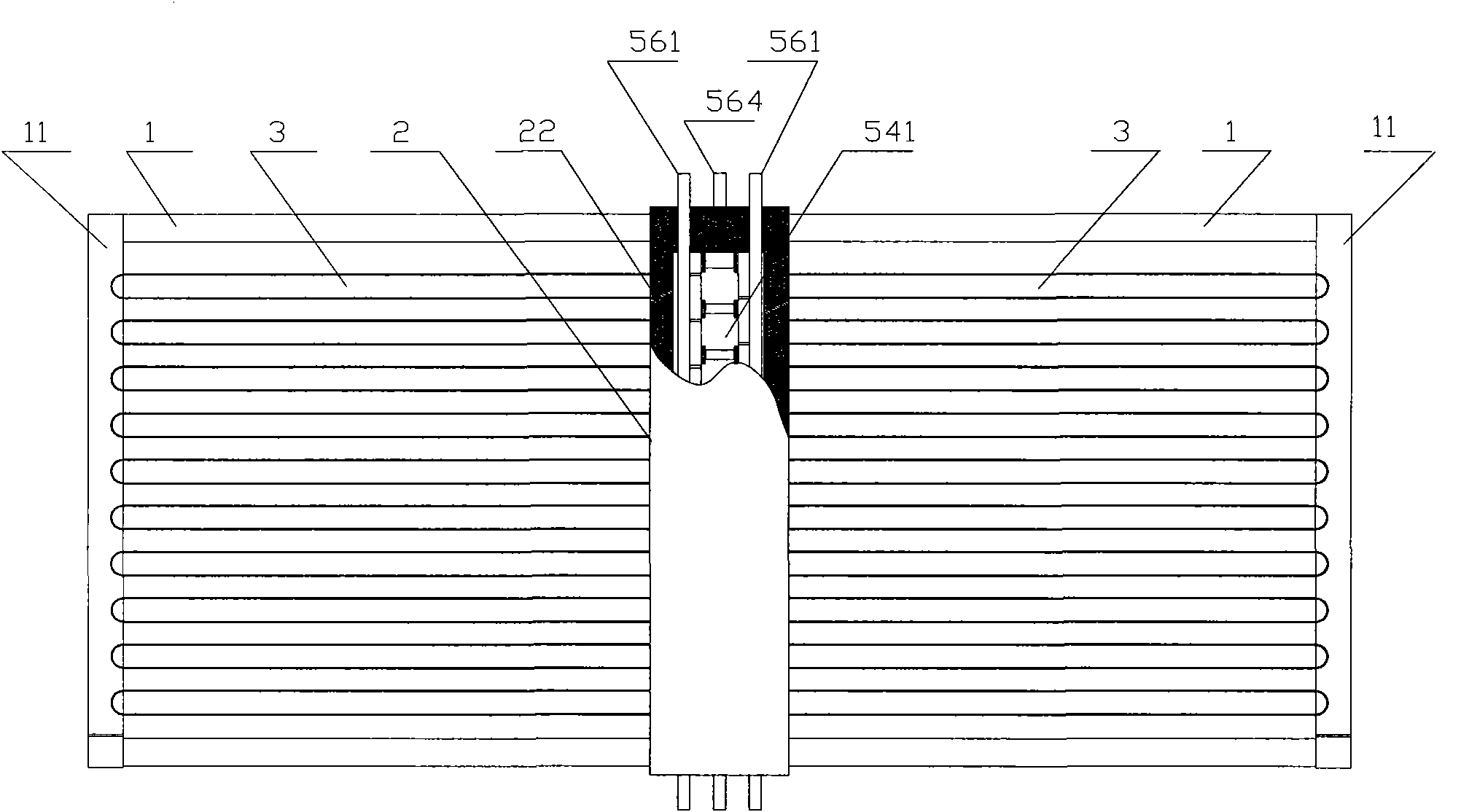

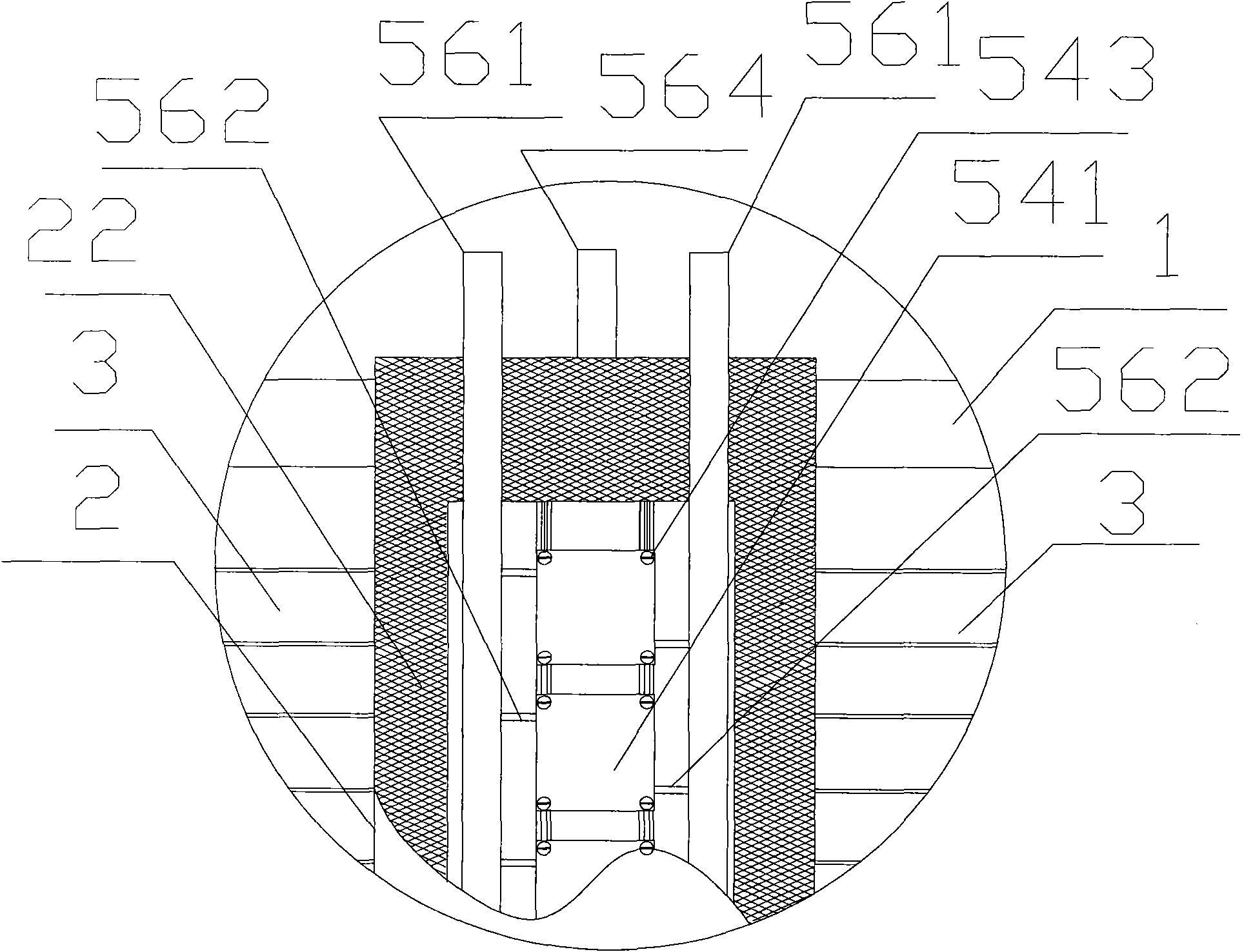

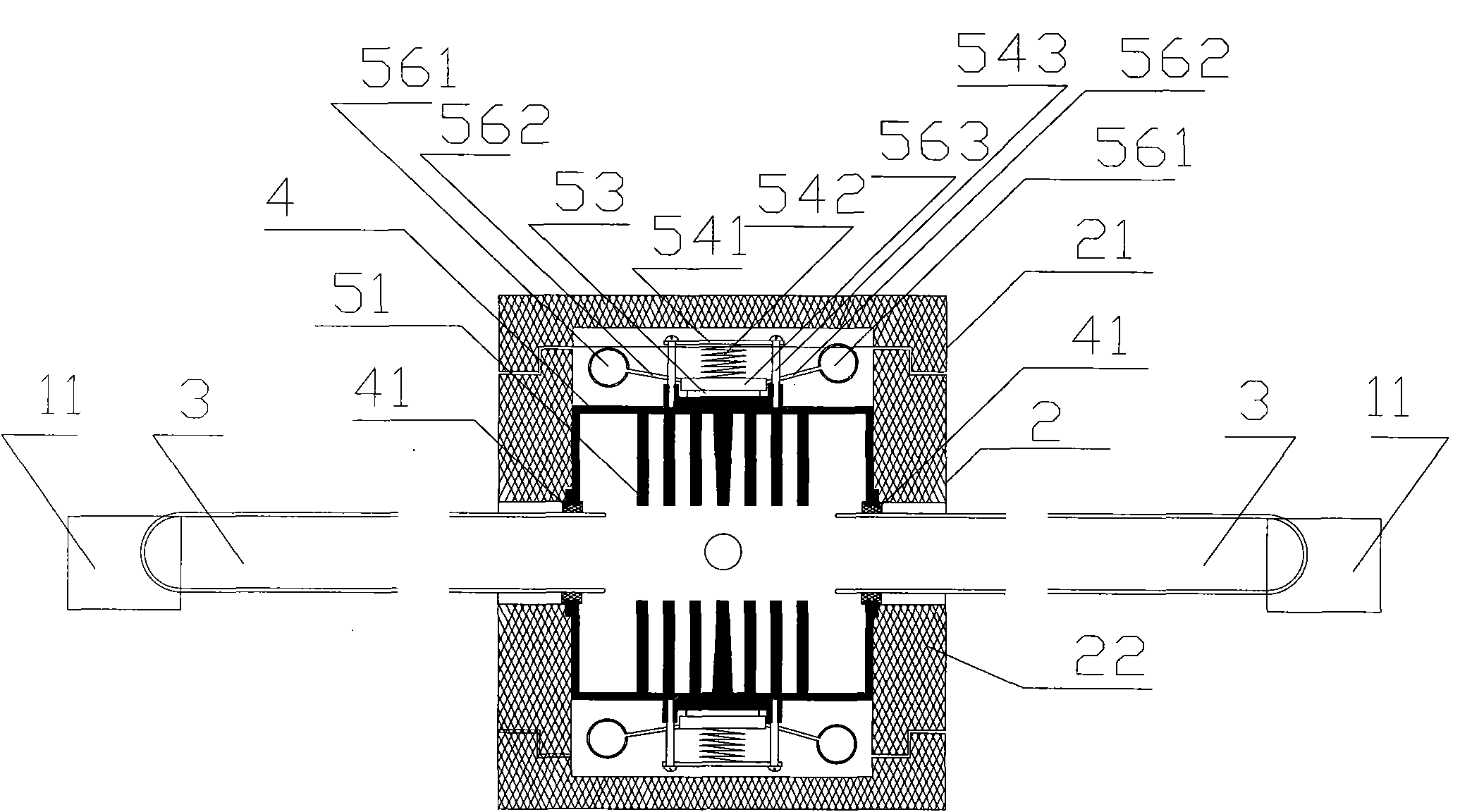

[0020] Such as figure 1 , figure 2 , image 3 As shown, the double-wing double-generation heat collector includes a protective outer box 2, a metal flow channel 4, a bracket 1, and several different-diameter or equal-diameter glass vacuum tubes 3 symmetrically arranged on both sides of the protective outer box. The metal flow channel 4 is closely combined with the The inner wall of the protective outer box 2 is filled with a thermal insulation layer 22 between the metal runner and the protective outer box, and polyurethane foam is selected. The protective outer box and several different-diameter or equal-diameter glass vacuum tubes on both sides are fixed on the rear stock 11 of the bracket 1. There are through holes on both sides of the protective outer box and the metal flow channel, and the different-diameter or equal-diameter glass vacuum tubes are inserted into the protective outer box. In the through holes on both sides of the box and the metal flow channel, each glas...

Embodiment 2

[0032] Such as image 3 As shown, the structure of the double-wing double-generation heat collector in this embodiment can also be designed as follows: including a protective outer box 2, a metal flow channel 4, a support 1, and several different-diameter or equal-diameter glass vacuum tubes 3 symmetrically arranged on both sides of the protective outer box The metal runner and the protective outer box are filled with excellent thermal insulation material as the thermal insulation layer 22. The protective outer box and a number of glass vacuum tubes with different diameters or equal diameters on both sides are fixed on the bracket, and both sides of the protective outer box and the metal runner are A through hole is opened, and glass vacuum tubes of different diameters or equal diameters are inserted into the through holes of the protective outer box, and several pairs of power generation module assemblies 5 are installed through the metal flow channels at the through holes. E...

Embodiment 3

[0038] Such as Figure 4 As shown, the structure of the double-wing and double-generation heat collector of the present embodiment is similar to that of Embodiment 2, but its structure of the power generation module assembly 5 is changed to: include a metal heat collector 51 with holes inside, a heat pipe 512 (select the heat pipe with the same diameter) Or two combined heat pipes with different diameters), a flat power generation module 53, a metal radiator 52, a protective cover 55, and several compression bolts 543.

[0039] The metal heat collector 51 is a solid block with holes matching the shape of the end of the heat pipe.

[0040] Described metal radiator 52 is the same as embodiment 2;

[0041] The power generation module 53 is placed between the heat collector 51 and the radiator 52. The power generation module is a flat DC semiconductor device with positive and negative lead wires, and its two planes are respectively a cold end plane and a hot end plane. The power ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com