Method of manufacturing a product comprising a fragrance compound

A compound and fragrance technology, which is applied in the printing, transportation, packaging and printing of special varieties of printed matter, can solve the problems of complicated technology and laboriousness, and achieve the effect of convenient measurement and easy measurement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

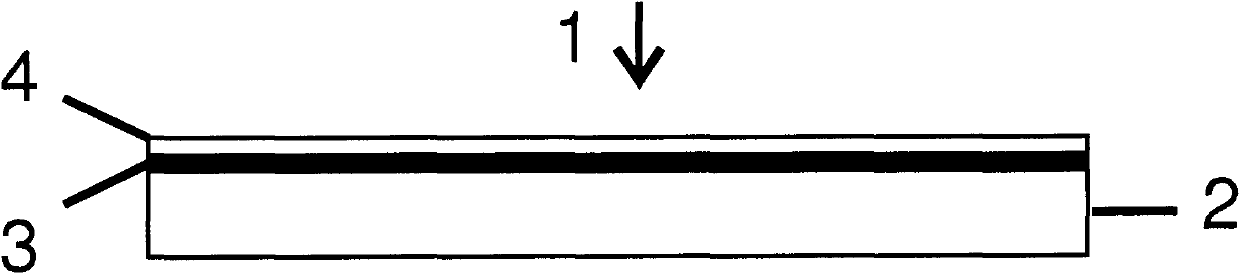

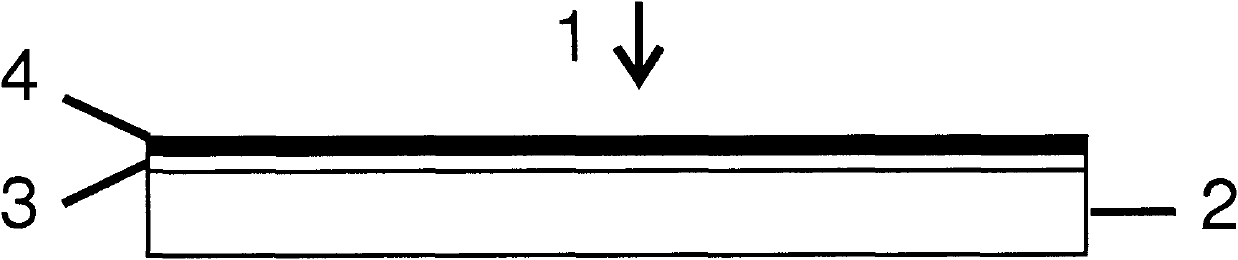

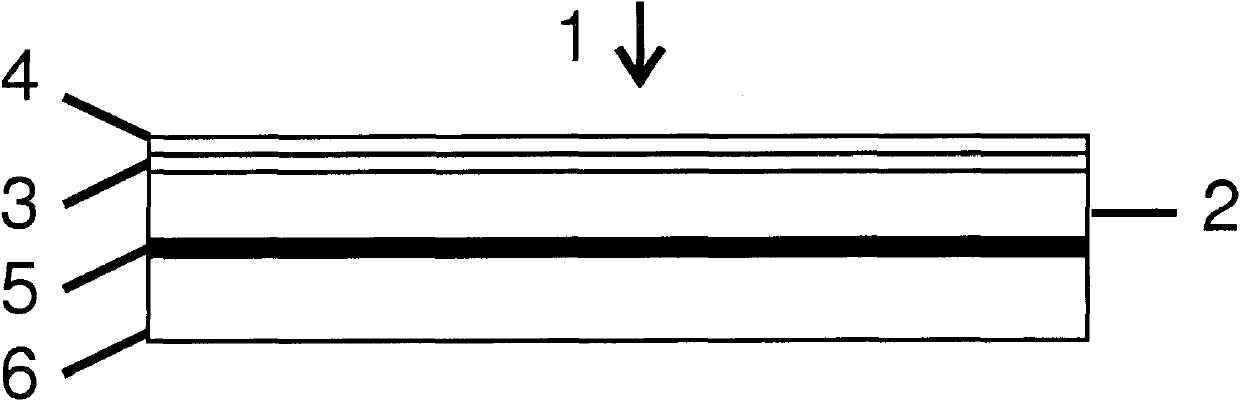

[0039] Some applications of the invention are shown in Figure 1-3 and in the three test instances.

[0040] exist figure 1 , scent compounds are printed on the ink.

[0041] exist figure 2 In, scent compounds are printed on the varnish.

[0042] exist image 3 In , scent compounds are printed on the adhesive.

[0043] figure 1The application of the invention is shown in detail, which illustrates a side cutaway view of a beer cap backing board. The product in this case, beer cap liner 1 , comprises a board as base material 2 on which printing ink 3 and varnish 4 are printed by a screen printing process. Fragrance compounds are added to printing ink 3.

[0044] figure 2 The application of the invention is shown in detail, which illustrates a side sectional view of the shelf card 1 . The product 1 comprises a plate as base material 2 on which a printing ink 3 and a screen printing varnish 4 are printed by a screen printing process. In this example, fragrance compou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com