Tower-type filtering device for biomass-based fermented mash

A technology based on fermented mash and tower filtration, applied in the direction of filtration separation, filtration circuit, separation method, etc., can solve the problem of reducing factory operating rate and economic benefits, and is easy to adhere to the wire filter 2 and the upper sieve plate 1 , Affect the normal operation of the mature mash concentration tower, etc., to achieve the effect of easy maintenance and high filtration efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be described in detail below with reference to the drawings and specific embodiments.

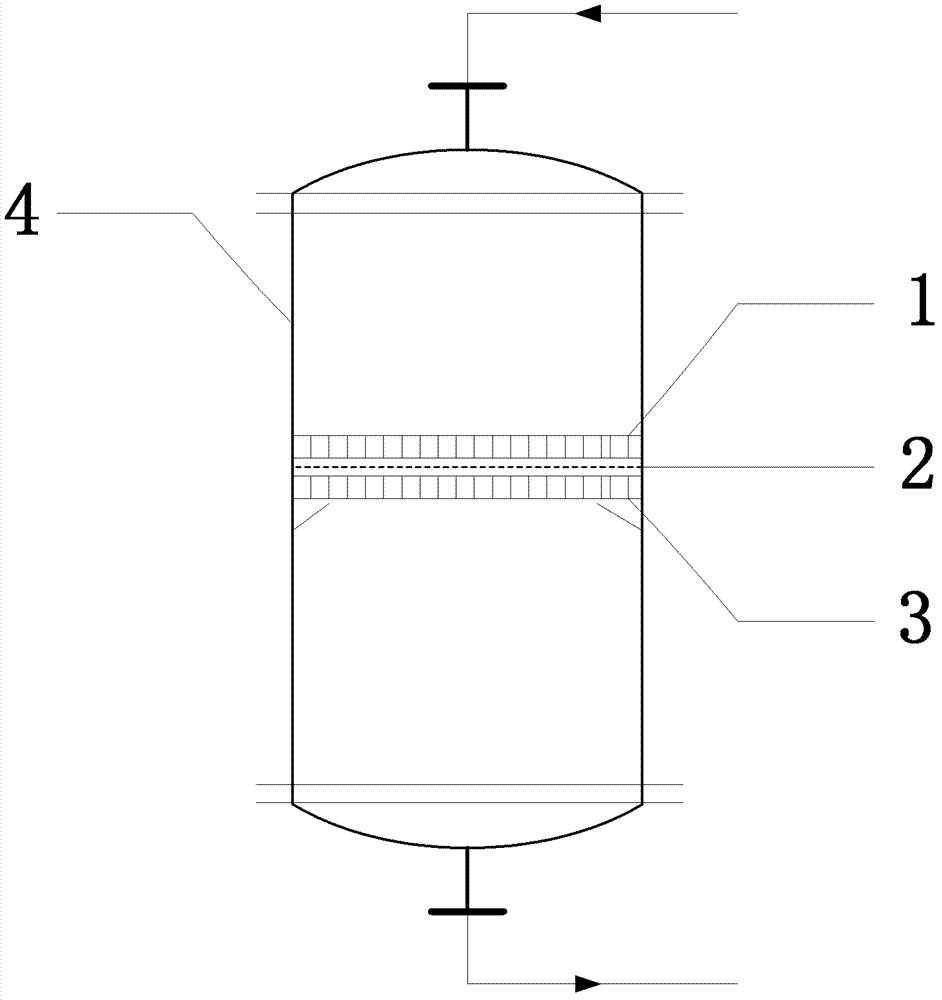

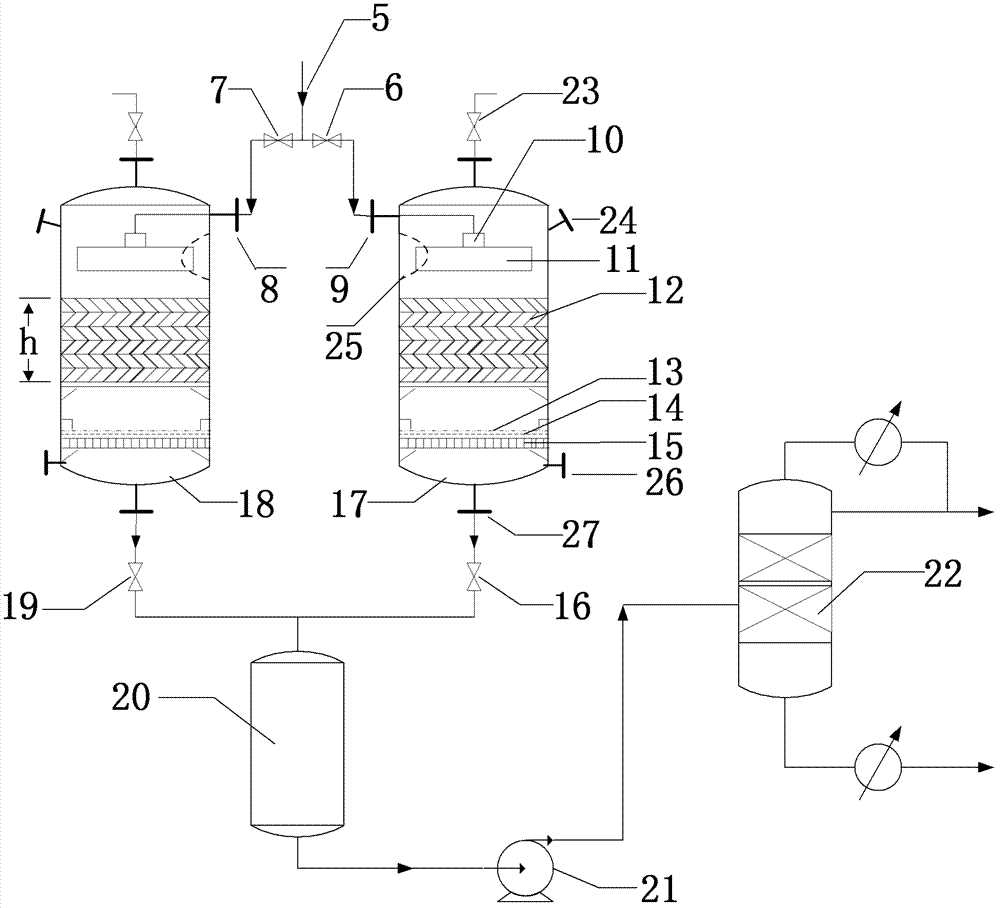

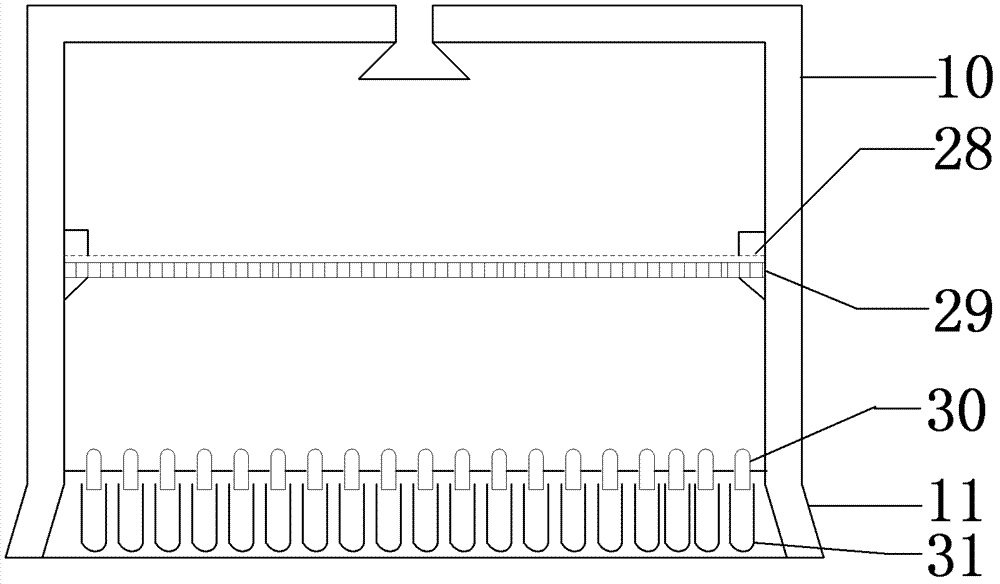

[0015] Such as figure 2 The shown tower filter device for biomass-based fermentation mash includes the same two tower filters 17, 18, and the discharge ports of the two tower filters each pass through a pipeline on which a valve is installed. It is connected to the inlet of the mature mash collection tank 20, and the outlet of the mature mash collection tank is connected to the inlet of the mature mash concentration tower 22 through a pipeline equipped with a centrifugal pump 21. The feed of the two tower filters The ports 9, 8 are respectively connected to the discharge pipe 5 from the mature mash storage tank through the inlet pipeline with valves 6, 7 on them, and are arranged in each tower filter at intervals from top to bottom. A three-stage filter unit, wherein the first-stage filter unit includes a shell, and a filter feed port connected to the feed po...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com