Core roll rotating device of vertical ring rolling machine

A technology of rotating device and ring rolling machine, which is applied in the direction of metal rolling, etc. It can solve the problems that the ring rolling process cannot be carried out, the ring blank cannot be carried, and pits are formed, and the structure is simple, the installation and adjustment are convenient, and the loss of waste products is reduced. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

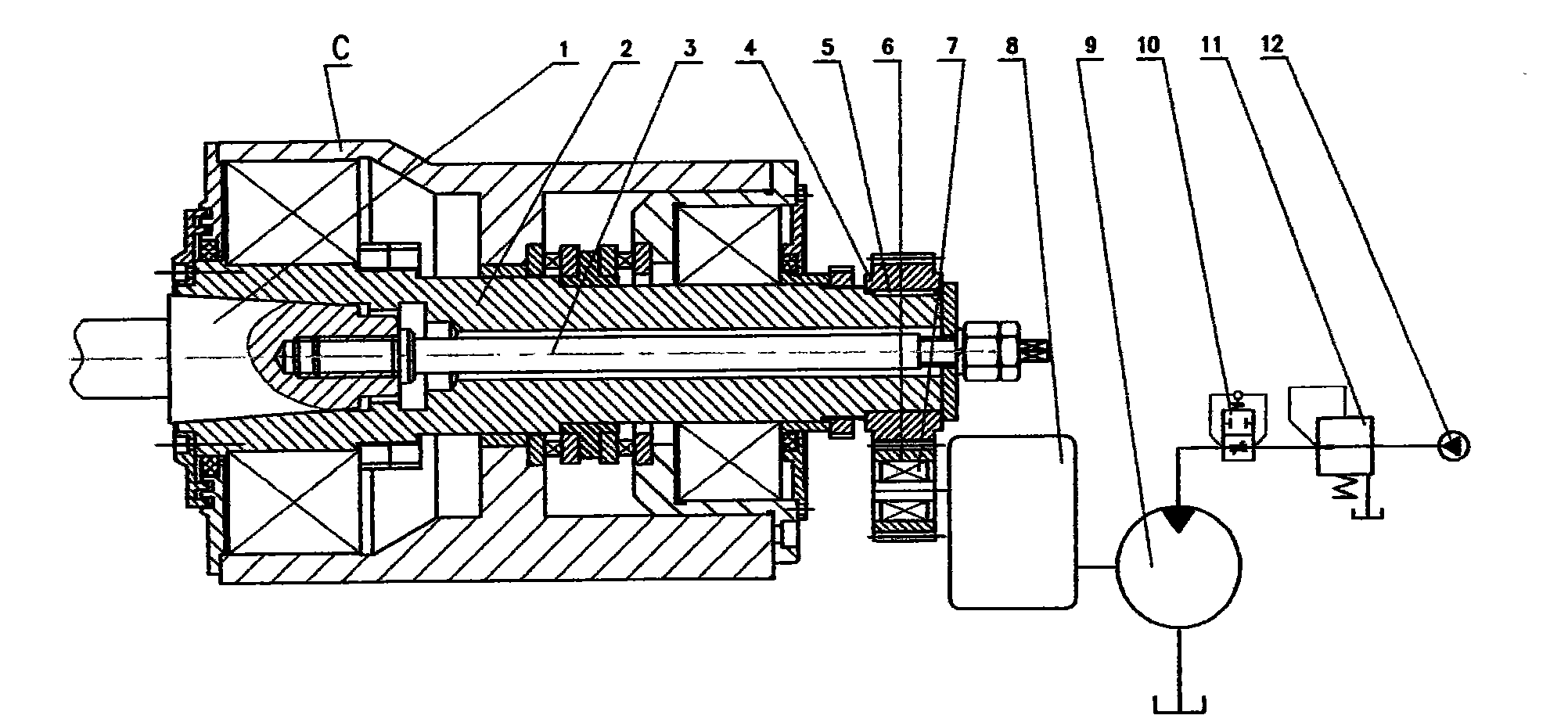

[0017] Embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

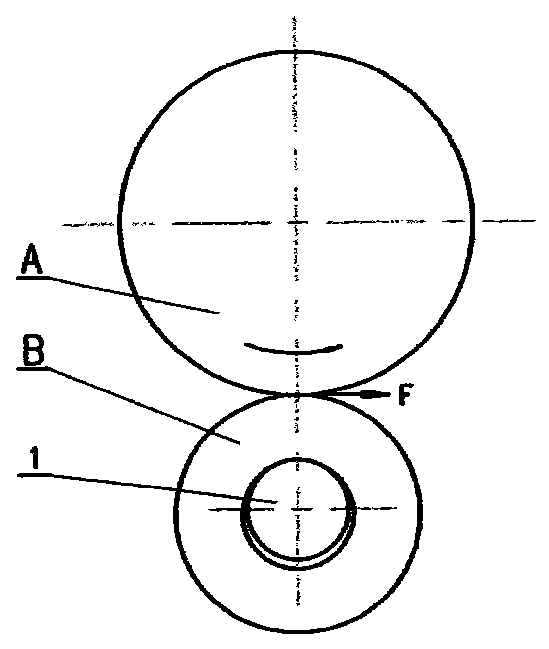

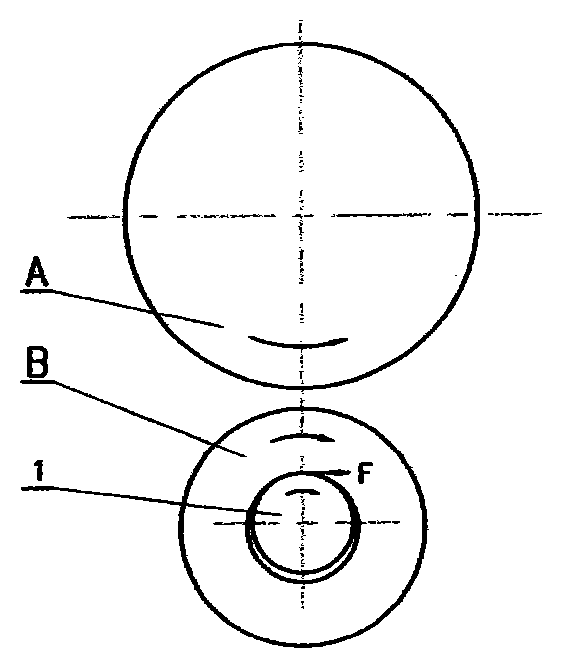

[0018] figure 1 When the vertical ring rolling machine is not equipped with this rotating device, the initial state of ring rolling with the core roll still, A is the main rolling wheel, B is the ring blank, and 1 is the core roll. The main rolling wheel A driven to rotate by the main motor and dragged down by the main oil cylinder, before contacting the ring blank B, the ring blank B and the core roller 1 are in a stationary state, and the main rolling wheel A cuts into the ring blank B After the outer periphery, the tangential friction force F overcomes the moment of inertia of the ring blank B, the core roller 1, etc. and other rotational resistances, and the belt swivel B and the core roller 1 rotate, and the rolling process begins. Because the tangential contact surface of the two outer circles is small, the contact is lightly pressed at the initia...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com