Trolley for detecting track of crane

A technology for cranes and rails, applied in the field of trolleys for detecting crane rails, which can solve problems such as high cost, poor measurement continuity, and high risk, and achieve the effects of lowering the center of gravity, preventing accidental overturning, and good stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

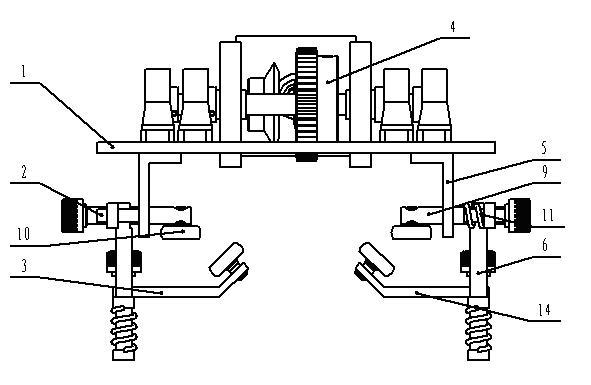

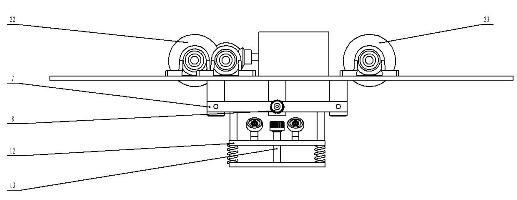

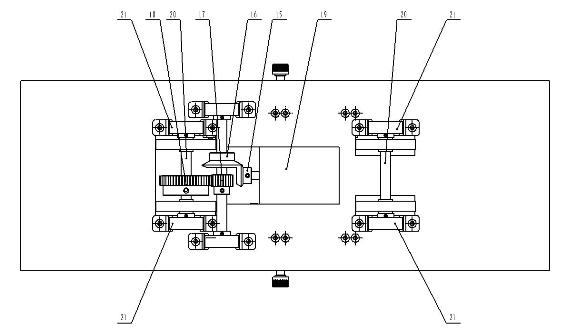

[0012] The specific implementation of the present invention will be described below in conjunction with the accompanying drawings.

[0013] like figure 1 , figure 2 , image 3 A trolley for detecting crane rails is shown, including a frame 1, a clamping mechanism 2, an anti-overturning mechanism 3, a drive system 4, a tripod 5, a guide column 6, a large adjustment plate 7, a large screw 8, and a pillar 9. Small wheel 10, pillar 9, spring 11, small adjustment plate 12, small screw 13, bracket 14, large bevel gear 15, small bevel gear 16, large spur gear 17, small spur gear 18, motor 19, shaft 20 , Rolling bearing seat 21, driving wheel 22, driven wheel 23.

[0014] Before the work starts, the track tester is installed on the trolley used to test the crane track. Place the trolley on the track, and position the small wheel on the clamping mechanism on one side of the trolley on one side of the crane track, and use the side of the track as the measurement reference. Adjust ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com