Preparation method of Zn-Al-Ti intermediate alloy

An intermediate alloy and aluminum alloy technology, applied in the field of metal alloy materials, can solve the problems of unstable absorption of refined elements, inability to accurately control the addition amount, and increase in production costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

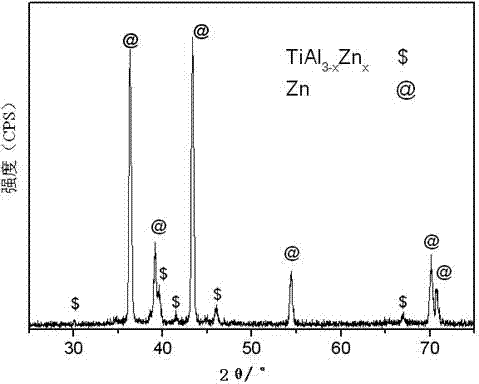

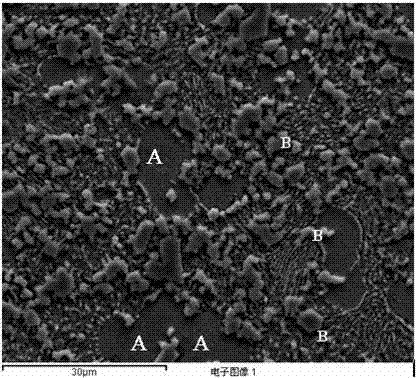

[0041] To prepare Zn-6.1wt.%Al-5wt.%Ti master alloy, according to the chemical composition of the master alloy, weigh Zn-10wt.%Al alloy and K 2 TiF 6 Powder the two raw materials to make K 2 TiF 6 It is 25.5% of the weight of zinc-aluminum alloy. Melt the Zn-10wt.%Al alloy to 600-780°C in a graphite clay crucible with a resistance furnace, and then add K 2 TiF 6 Add the powder to the surface of the Zn-10wt.%Al alloy melt in two batches, and then continue to keep warm for 2-15 minutes after adding it completely, and pour the upper oil melt in the crucible into the solidification mold to separate it from the lower alloy melt , the lower alloy melt is fully stirred and poured into another mold, and after cooling, the Zn-6.1wt.%Al-5wt.%Ti master alloy can be obtained. XRD ( figure 1 ) and SEM ( figure 2 ) analysis shows that the matrix of this alloy is mainly η-Zn, and TiAl with a size of 0.3-3 μm is dispersed in the matrix 3-x Zn x (0.4figure 2 shown in B).

[0042] Ad...

Embodiment 2

[0044] To prepare Zn-35wt.%Al-15wt.%Ti master alloy, according to its chemical composition, weigh Zn-48wt.%Al alloy and K 2 TiF 6 Powder the two raw materials to make K 2 TiF 6 It is 79% of the weight of Zn-48wt.%Al alloy. The Zn-48wt.%Al alloy was melted to 600-780°C in a graphite clay crucible with an induction furnace, and then K 2 TiF 6 Add the powder to the surface of the Zn-48wt.%Al alloy melt in four batches, and then continue to keep warm for 2-15 minutes after adding it completely, and pour the upper oil melt in the crucible into the solidification mold to separate it from the lower alloy melt , and then the lower alloy melt is fully stirred and poured into the mold. After cooling, the Zn-35wt.%Al-15wt.%Ti master alloy can be obtained. XRD ( Figure 5 ) and SEM ( Figure 6 ) analysis shows that the matrix of this master alloy is mainly η-Zn and α-Al, and TiAl with a size of 0.3-3 μm is dispersed in the Zn-Al matrix 3-x Zn x (0.4

Embodiment 3

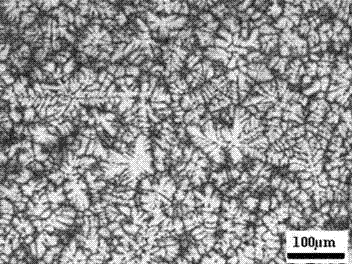

[0046] To prepare Zn-27wt.%Al-6.2wt.%Ti master alloy, weigh Zn-32wt.%Al alloy and K 2 TiF 6 Powder the two raw materials to make K 2 TiF 6 It is 32% of the weight of Zn-32wt.%Al alloy. Melt the Zn-32wt.%Al alloy to 600-780°C in a graphite clay crucible with a power frequency induction furnace, and then add K 2 TiF 6 Add the powder to the surface of the Zn-32wt.%Al alloy melt in three batches, and then continue to keep warm for 2-15 minutes after adding it completely, and pour the upper oil melt in the crucible into the solidification mold to separate it from the lower alloy melt , and then the lower alloy melt is fully stirred and poured into the mold, and after cooling, the Zn-27wt.%Al-6.2wt.%Ti master alloy can be obtained. This master alloy matrix is mainly η-Zn and α-Al ( Figure 7 , Figure 8 ), and TiAl with a diameter of mostly 0.3-3 μm is dispersed in the Zn-Al matrix 3-x Zn x (0.4 Figure 8 ). Adding this master alloy into the Zn-25Al alloy melt at 560°C ca...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com