Preparation method of zinc-aluminum-titanium-boron intermediate alloy

A technology of master alloy and pure aluminum, which is applied in the field of metal alloy materials to achieve the effect of avoiding process increase and efficient grain refinement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

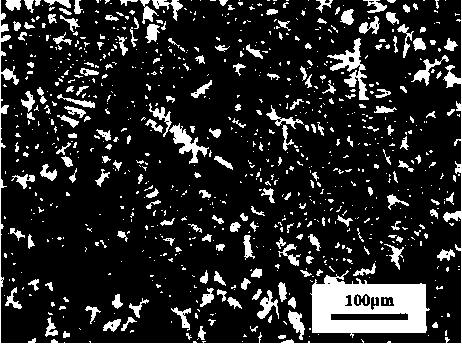

Image

Examples

Embodiment 1

[0026] Prepare 10 kilograms of Zn-46wt.%Al-6wt.%Ti-1B master alloy as follows:

[0027] (1) Weigh the following raw materials according to the following mass ratio: 47% pure zinc ingot, 40% pure aluminum ingot, 6% pure aluminum powder (average particle size 76μm), 6% pure titanium powder (average particle size 76μm), pure Boron powder (average particle size 4μm) 1%;

[0028] (2) Use a ball mill to mill the titanium powder, boron powder and aluminum powder in an argon atmosphere for 2 hours to fully mix the three powders evenly, then take out the mixed powder, and use a press under the condition of a pressure of 10MPa Press down to form a block and set aside. Wherein, the quality of each compressed block is 130 grams;

[0029] (3) Melt pure aluminum ingots to 1100°C in a medium-frequency induction furnace, press the powder compact block obtained in step (2) into the molten aluminum, and after the block is added to the molten aluminum, it will chemically react with the molten ...

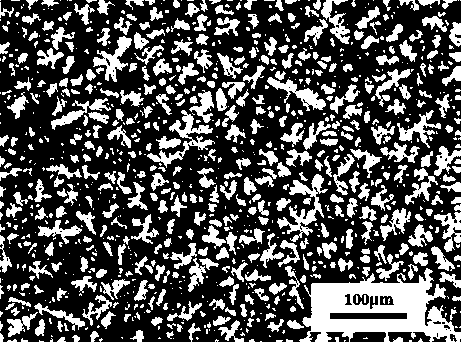

Embodiment 2

[0035] Prepare 5 kilograms of Zn-30wt.%Al-3wt.%Ti-2B master alloys as follows:

[0036] (1) Weigh the following raw materials according to the mass ratio of the above-mentioned master alloy chemical composition: 65% pure zinc ingot, 24% pure aluminum ingot, 6% pure aluminum powder (average particle size 76μm), pure titanium powder (average particle size 76μm) 3%, pure boron powder (average particle size 1μm) 2%;

[0037](2) Mill the weighed titanium powder, boron powder and aluminum powder with a ball mill in an argon atmosphere for 1 hour to fully mix the three powders evenly, then take out the mixed powder, and use a press under the condition of a pressure of 15MPa Press down to form a block and set aside. Wherein, the quality of each compressed block is 55 grams;

[0038] (3) Use a medium frequency induction furnace to melt pure aluminum ingots to 1100°C, press the powder compacts obtained in step (2) into molten aluminum one by one, after adding the molten aluminum, the ...

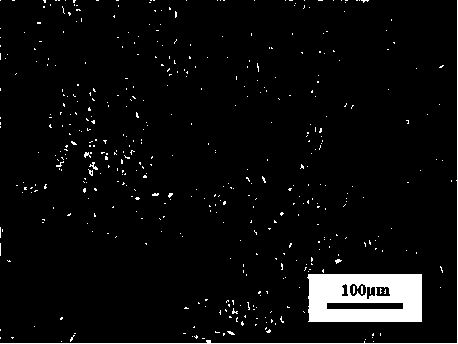

Embodiment 3

[0043] Prepare 10 kilograms of Zn-40wt.%Al-4wt.%Ti-0.5B master alloy as follows:

[0044] (1) Weigh the following raw materials according to the mass ratio of the above-mentioned master alloy chemical composition: 55.5% pure zinc ingot, 36% pure aluminum ingot, 4% pure aluminum powder (average particle size 76μm), pure titanium powder (average particle size 76μm) 4%, pure boron powder (average particle size 6μm) 0.5%;

[0045] (2) Use a ball mill to mill the titanium powder, boron powder and aluminum powder in an argon atmosphere for 3 hours to fully mix the three powders evenly, then take out the mixed powder, and use a press under the condition of a pressure of 10MPa Press down to form a block and set aside. Wherein, the quality of each compressed block is 85 grams;

[0046] (3) Use a medium frequency induction furnace to melt pure aluminum ingots to 1000°C, press the powder compacts obtained in step (2) into molten aluminum one by one, after adding the molten aluminum, th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com