High-toughness high-thermal-conductivity easy-to-weld aluminum-based composite material for 5G base station and preparation method

An aluminum-based composite material with high thermal conductivity technology, applied in the field of aluminum-based composite materials, can solve the problems of alloy thermal conductivity, unfavorable formability, reduction of alloy thermal conductivity, corrosion resistance, plastic toughness, grain growth, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] The composition (mass percentage) of the composite material is as follows: Si 1.2, Fe 0.8, Cu 0.1, Mn 1.5, Zr0.8, Ti0.8, B 1.0, O 0.8, Er 0.2, Sc 0.2, Y 0.2, Zn 0.2, Mg 0.2 , Cr 0.2, and the rest are Al.

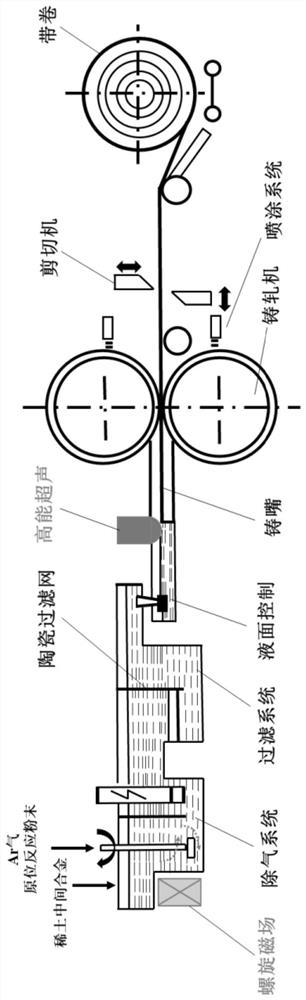

[0031] In an industrial natural gas smelting furnace, add 5T of industrial pure aluminum ingots, melt to 870°C and keep warm, then weigh and add Al-20Si, Al-20Cr, Fe agent (content 70%), Mn agent (content 70%), Pure Cu, pure Zn, pure Mg, etc. adjust the alloy composition to the design value; pour it into the holding furnace (850°C) of the electromagnetic ultrasonic control twin-roll continuous casting and rolling device, start the stirring degassing system and the electromagnetic stirring system, with the help of the purity of 99.99% Ar gas, blown into the weighed and dried K from the degassing pipeline 2 ZrF 6 、K 2 TiF 6 、KBF 4 and Na 2 B 4 o 7 Mixing powders to generate nano-ZrB in situ with Al melt 2 、Al 2 o 3 、TiB 2 Ceramic particles, the total time fo...

Embodiment 2

[0033] The composition (mass percentage) of the composite material is as follows: Si 1.0, Fe 0.6, Cu 0.05, Mn 1.0, Zr 0.5, Ti 0.5, B 0.5, O 0.5, Er 0.05, Sc 0.05, Y 0.05, Zn 0.5, Mg 0.5, Cr 0.5, the rest is Al.

[0034] In an industrial natural gas smelting furnace, add 5T of industrial pure aluminum ingots, melt to 900°C and keep warm, then weigh and add Al-20Si, Al-20Cr, Fe agent (content 70%), Mn agent (content 70%), Pure Cu, pure Zn, pure Mg, etc. adjust the alloy composition to the design value; pour it into the holding furnace (870°C) of the electromagnetic ultrasonic control twin-roll continuous casting and rolling device, start the stirring degassing system and the electromagnetic stirring system, with the help of the purity of 99.99% Ar gas, blown into the weighed and dried K from the degassing pipeline 2 ZrF 6 、K 2 TiF 6 、KBF 4 and Na 2 B 4 o 7 Mixing powders to generate nano-ZrB in situ with Al melt 2 、Al 2 o 3 、TiB 2 For ceramic particles, the total tim...

Embodiment 3

[0036] The composition (mass percentage) of the composite material is as follows: Si 1.5, Fe 1.0, Cu 0.2, Mn 2.0, Zr1.0, Ti1.0, B 2.0, O 1.0, Er 0.3, Sc 0.3, Y 0.5, Zn 0.1, Mg 0.1 , Gr 0.1, the rest is Al.

[0037] In the industrial natural gas smelting furnace, add 5T of industrial pure aluminum ingot, melt it at 900°C and keep it warm, then weigh and add Al-20Si, Al-20Cr, Fe agent (content 70%), Mn agent (content 70%), Pure Cu, pure Zn, pure Mg, etc. adjust the alloy composition to the design value; pour it into the holding furnace (890°C) of the electromagnetic ultrasonic control twin-roll continuous casting and rolling device, start the stirring degassing system and the electromagnetic stirring system, with the help of the purity of 99.99% Ar gas, blown into the weighed and dried K from the degassing pipeline 2 ZrF 6 、K 2 TiF 6 、KBF 4 and Na 2 B 4 o 7 Mixing powders to generate nano-ZrB in situ with Al melt 2 、Al 2 o 3 、TiB 2 Ceramic particles, the total time f...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Grain | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com