A high-performance wire production process method and device

A production process, high-performance technology, applied in manufacturing tools, metal processing equipment, workpiece surface treatment equipment, etc., to achieve continuous and efficient introduction, uniform grain size and shape distribution, and simple operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0058] The T2 strip with a thickness of 100 μm and a width of 5 mm was subjected to a single-pass liquid-cooled temperature-controlled ultrasonic rolling continuous impact thinning treatment. The chemical composition of the T2 rolled pure copper foil used is shown in Table 1:

[0059] Table 1 Chemical composition of T2 calendered pure copper foil (%)

[0060] Cu Bi Sb Pb As S O ≥99.90 ≤0.002 ≤0.002 ≤0.005 ≤0.002 ≤0.005 ≤0.006

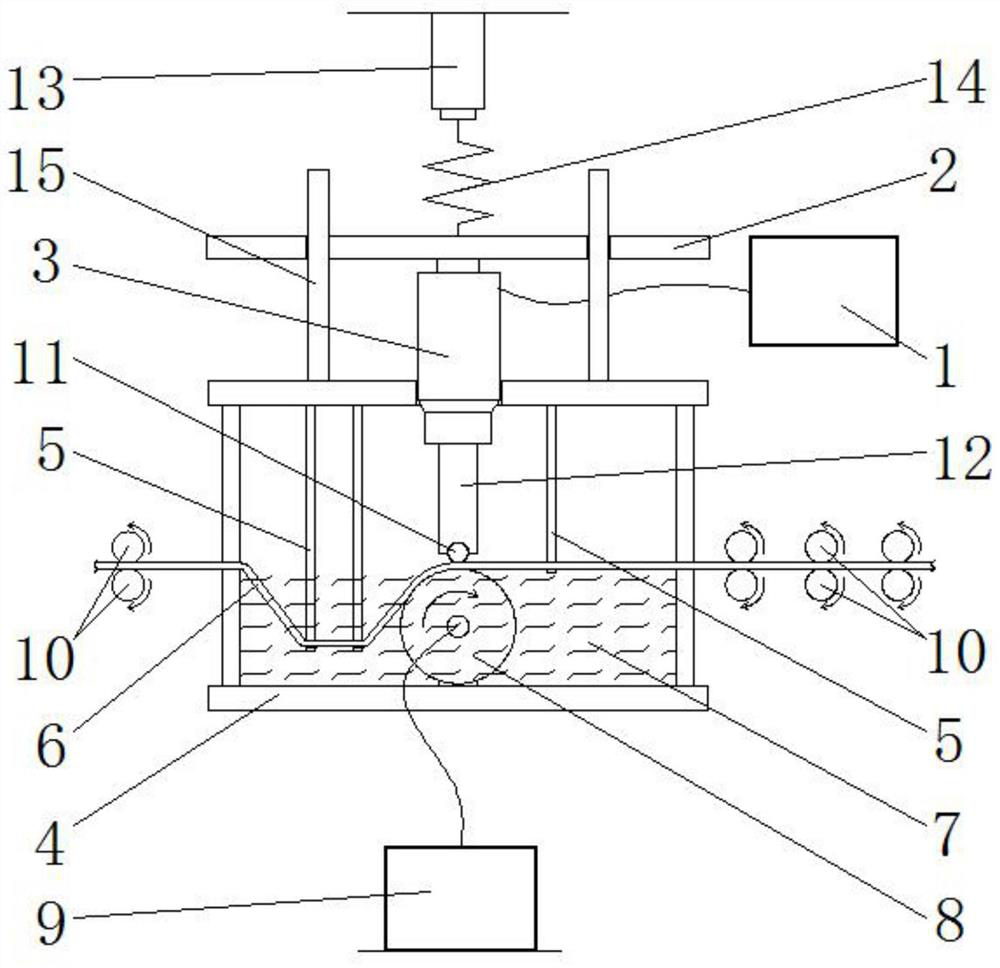

[0061] The low-temperature ultrasonic rolling impact device used is as follows: figure 1 , figure 2 , image 3 and Figure 4 as shown,

[0062] The device includes a closed liquid cooling temperature control mechanism, a traction transmission mechanism and an ultrasonic rolling impact mechanism;

[0063] The airtight liquid cooling temperature control mechanism includes an airtight container 4 with cooling liquid 7 inside, the outer shell of the airtight container 4 is a double-layer structure, and the inner layer...

Embodiment 2

[0080] The 304 austenitic stainless steel wire with a width and thickness of 300 μm was subjected to multi-pass liquid-cooled temperature-controlled ultrasonic rolling continuous impact treatment, and the low-temperature ultrasonic rolling impact device used was the same as that in Example 1.

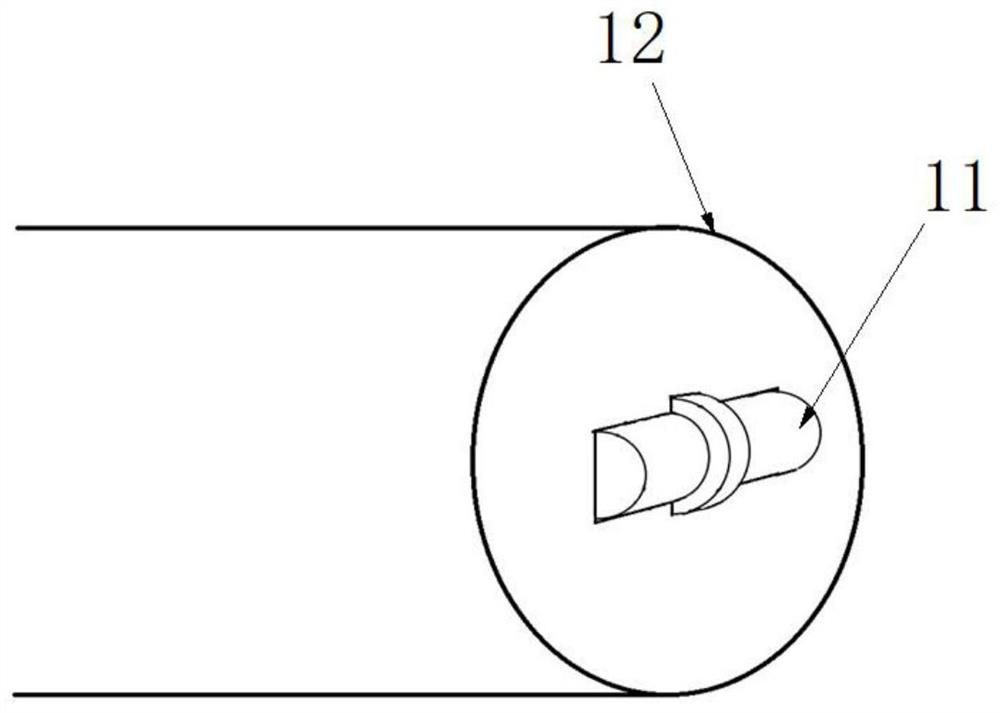

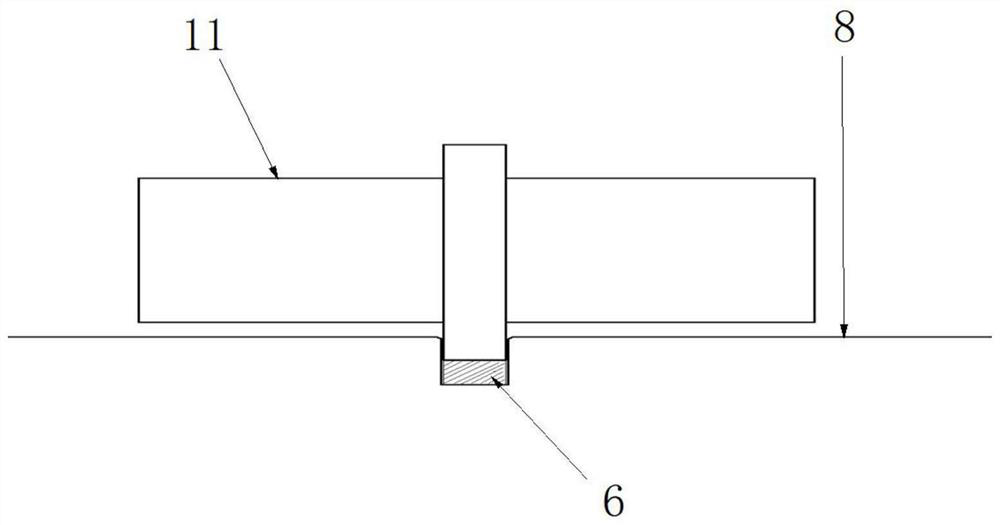

[0081] The above-mentioned ultrasonic transducer 3 converts electrical vibration into 20 kHz ultrasonic waves, and the ultrasonic horn further amplifies the amplitude to drive the GCr15 bearing steel rigid impact roller 11 (diameter 6 mm, width 10 mm; surface groove width 300μm, depth 1mm; surface roughness (Ra): 0.1μm, hardness: 64 HRC) to generate longitudinal high-frequency vibration; use a laser displacement sensor to measure the vibration amplitude, and the end amplitude is 30μm; fix the ultrasonic horn to make the impact The distance between the rigid roller column 11 and the rigid roller 8 is the sum of the ultrasonic amplitude and half the thickness of the wire, that is, 30+150=1...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com