A method for improving the low-temperature and room-temperature color performance of carbonless copy paper

A carbonless copy paper, low temperature technology, applied in the field of improving the color rendering performance of carbonless copying paper at low temperature and normal temperature, and improving the color rendering performance of carbonless copying paper, can solve the problems such as slow color development speed, difficulty in meeting use requirements, application restrictions, etc. The effect of increasing the color development speed and improving the color optical density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

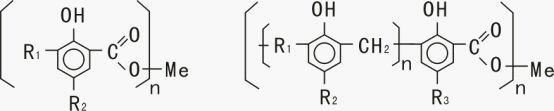

Method used

Image

Examples

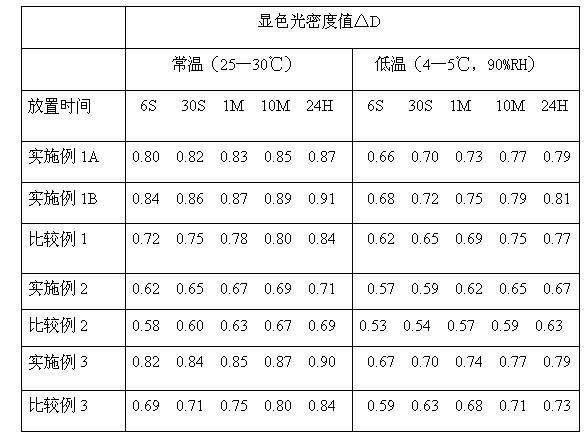

Embodiment 1A

[0026] Example 1A Preparation of Zinc Salicylate Resin Developer (Ⅲ) Emulsion Containing Lithium Chloride

[0027] Add 200 parts of solid zinc salicylate resin developer (Ⅲ), 0.5 parts of emulsifier, 1 part of lithium chloride, and 150 parts of water into the emulsification tank, heat up to 95 ° C, stir for 30 minutes, emulsify, and cool to 40 ℃, make zinc salicylate resin developer emulsion, and set aside.

[0028] Take the above-mentioned color developer emulsion to prepare CF coating, and the formula composition is as follows:

[0029] CF formula composition Servings

[0030] Zinc salicylate resin developer (Ⅲ) (containing 0.5% lithium chloride) 14.0*

[0031] Kaolin 33.5

[0033] Oxidized starch 9.8

[0034] Hydroxybutadiene Latex 6.0

[0035] water 105.0

[0036] *Contains 0.07 parts of lithium chloride

Embodiment 1B

[0038] The amount of lithium chloride added in Example 1A is increased from 1 part to 2 parts (lithium chloride in the resin developer is increased to 1%), and other conditions are the same as Example 1A, emulsification is made into developer emulsion, and then Take the above-mentioned developer emulsion, and prepare CF coating according to Example 1A, wherein lithium chloride is 0.14 parts.

Embodiment 2

[0039] Example 2 Preparation of Activated Clay Color Developer (I) Containing Lithium Hydroxide

[0040] Take 200 parts of activated clay (I), 2 parts of lithium hydroxide, 1 part of dispersant, 50 parts of PVA solution (10%), and 150 parts of water, put them in a grinder and grind for 30 minutes, take them out for use.

[0041] Take the above-mentioned activated clay color developer (I) to prepare CF coating. Formula composition except that the color developer containing activated clay and lithium hydroxide is used to replace the zinc salicylate resin color developer in Example 1B, the rest of the composition and dosage are the same as in Example 1B, and the color developer contains lithium hydroxide 1%, which is equivalent to 0.14 parts of lithium hydroxide in the formula.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com