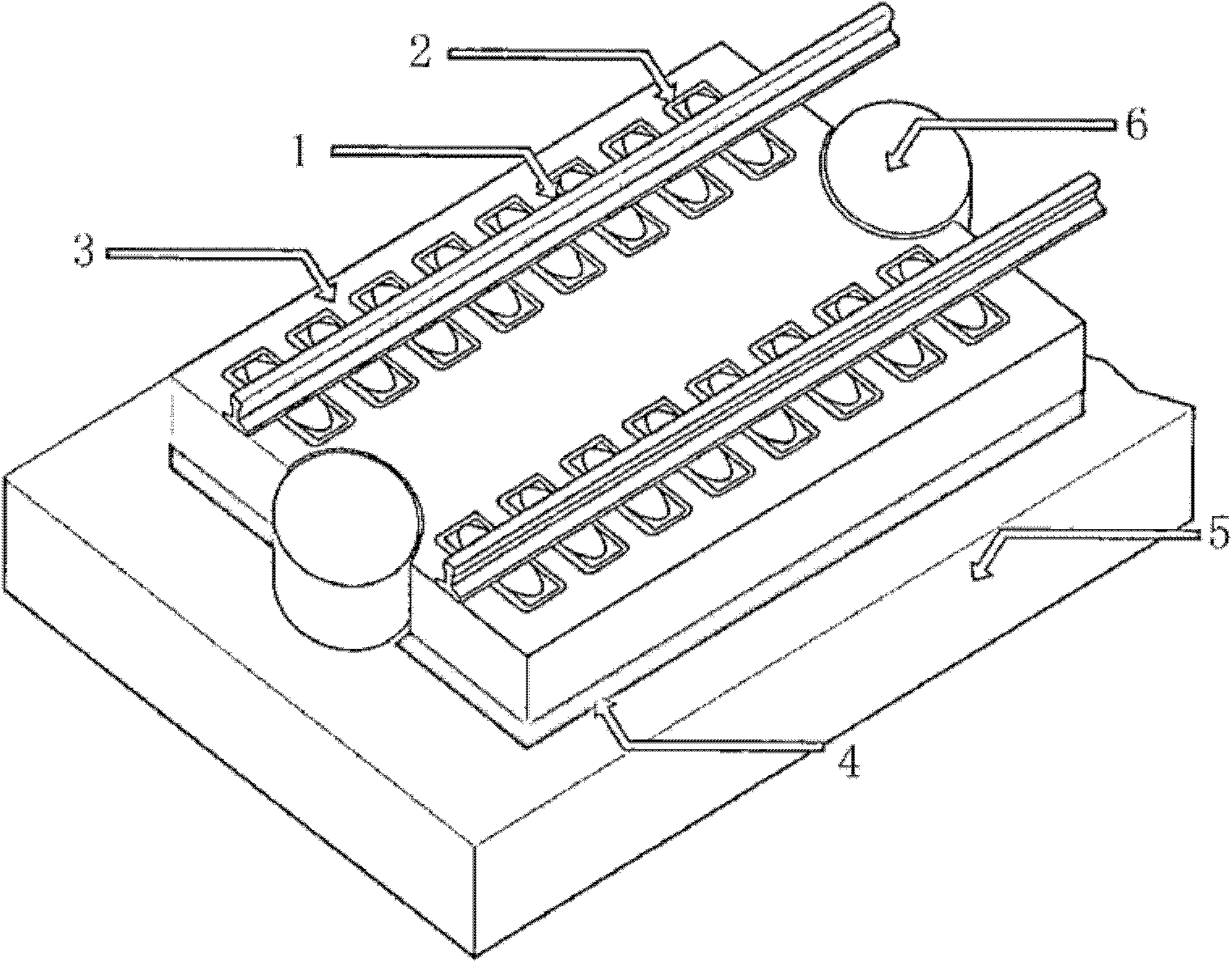

Track slab fine adjustment method and track laying method based on this method

A track slab and fine adjustment technology, which is applied in the directions of track, track laying, track maintenance, etc., can solve the difficulty of measuring the fine adjustment method, the measurement control of the lap joint between the slabs, the unfavorable control of the microwave smoothness of the ballastless track, and the fine tuning of the short wave of the slab section. Roughness error and other problems, to achieve the effect of favorable smoothness, high accuracy and short operation time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

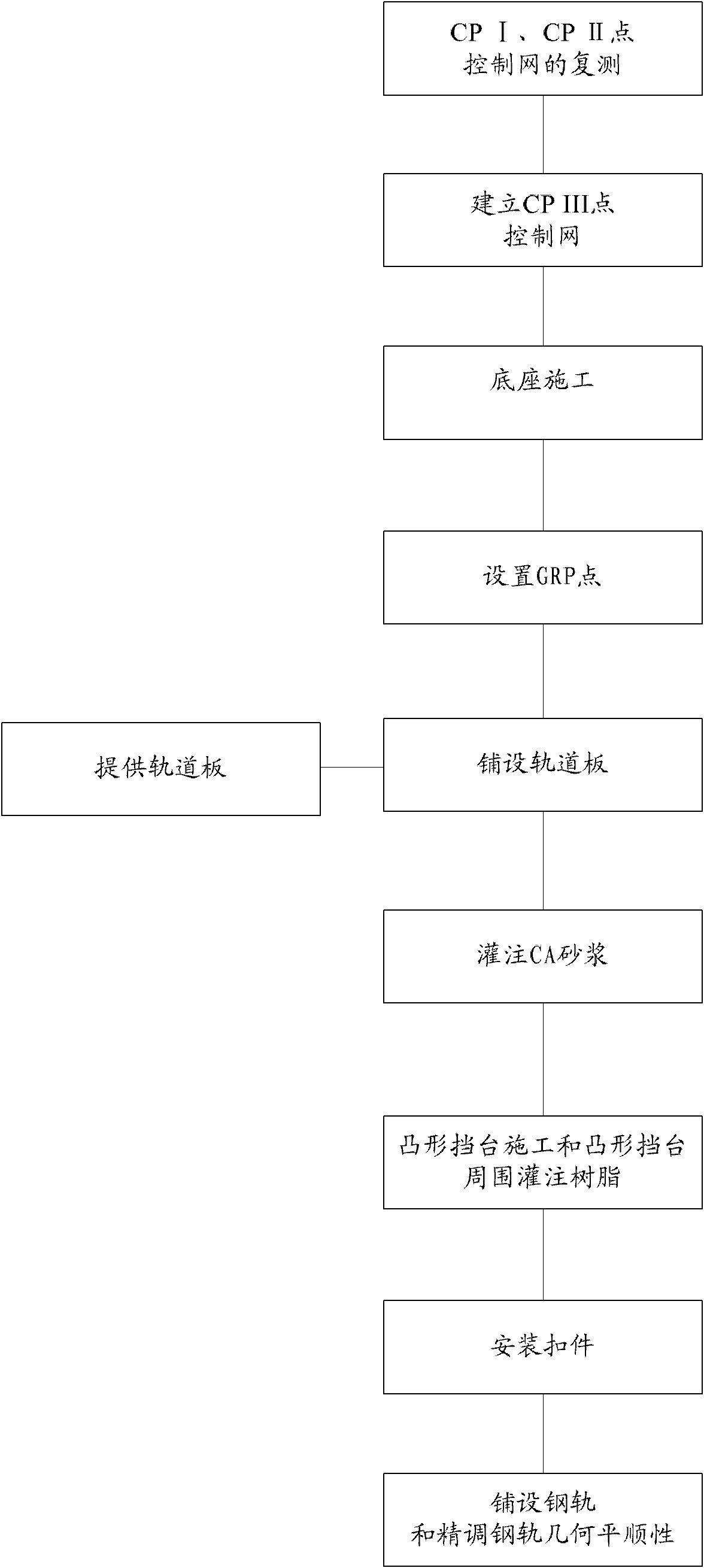

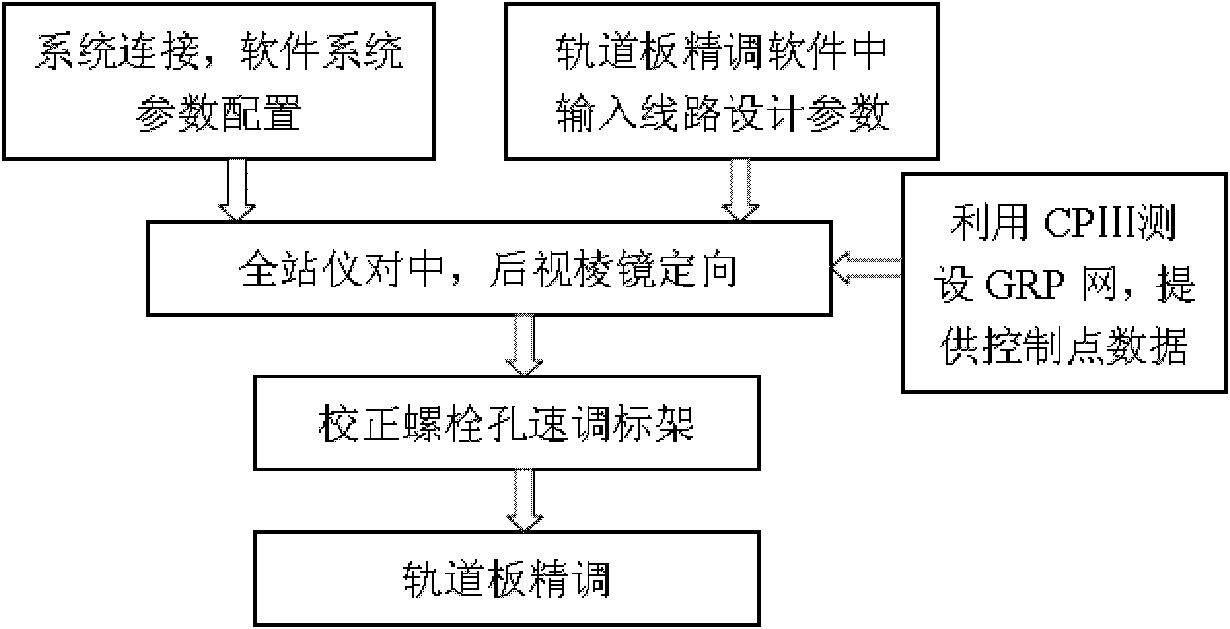

[0026] The terms CP (Control Point) I, II, and III used in the present invention are known in the art, and may also be referred to as primary, secondary or tertiary control points. Among them, the setting of CP I (that is, the first-level control point) is based on the relevant standards of the Ministry of Railways; while the CP II point is determined before the line construction. The above-mentioned CP I and II points exist as known standard point forms in the track laying process including the fine adjustment of the track slab, that is, its mileage and coordinates are all known and do not need to be readjusted and measured, but the present invention It is not excluded to retest the CP I and II points in the laying method.

[0027] The term "backsight" as used in the present invention is known in the art and specifically refers to placing a total station at a part or location to be measured or adjusted (such as a track plate being fine-tuned or a surveying In the case of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com