Lifting system for precast pier caps

A lifting system and a technology for pre-casting piers, applied in the field of lifting systems, can solve problems such as large pier cap loads, and achieve the effects of dispersing the load and shortening the construction period

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045] Hereinafter, the structure of the lifting and lowering system for precast pier caps of the present invention will be described in detail with reference to the accompanying drawings.

[0046]Hereinafter, when describing the present invention, if the specific description of related known functions or structures may obscure the gist of the present invention, the detailed description will be omitted. In addition, the terms described below are terms defined in consideration of functions in the present invention, and therefore may vary depending on the user's or operator's intention or custom. Therefore, its definition should be based on the entire content of this specification.

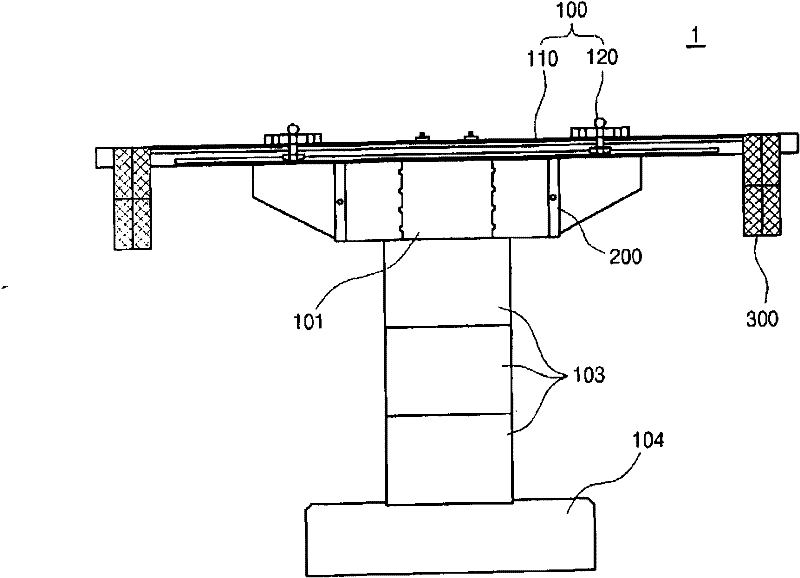

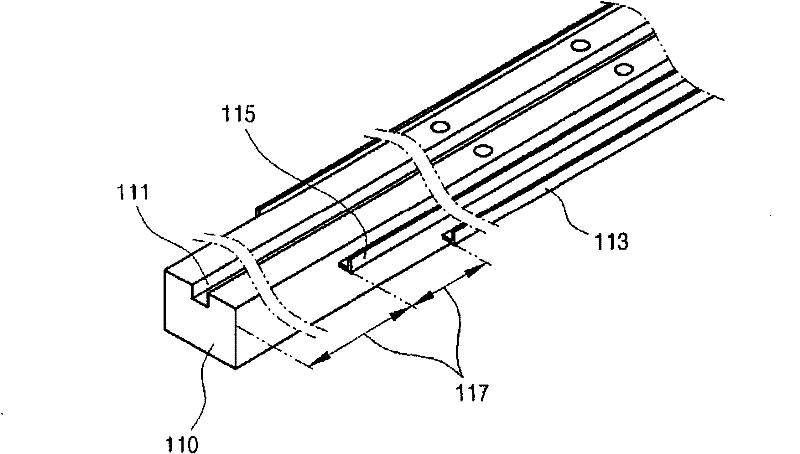

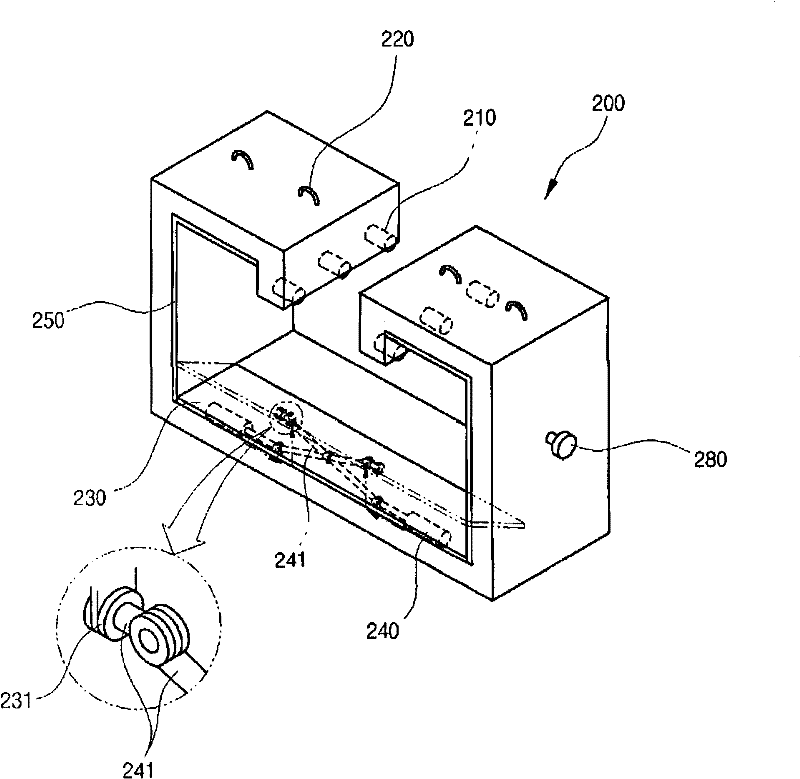

[0047] figure 1 is a side view showing the lifting system for precast pier caps of the present invention; figure 2 It is a side structural view showing the mid-level support platform structure of the lifting system for the precast pier cap of the present invention; image 3 It is an oblique view...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com