Liquid pressure transmission engine and driving method thereof

A pressure and engine technology, applied in the field of liquid pressure transmission engine and its drive, can solve the problems of high cost, inability to attract consumers' willingness to buy, and users' troubles in use.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The implementation of the present invention is described below with reference to specific examples, and those skilled in the art can easily understand other advantages and effects of the present invention from the content disclosed in this specification.

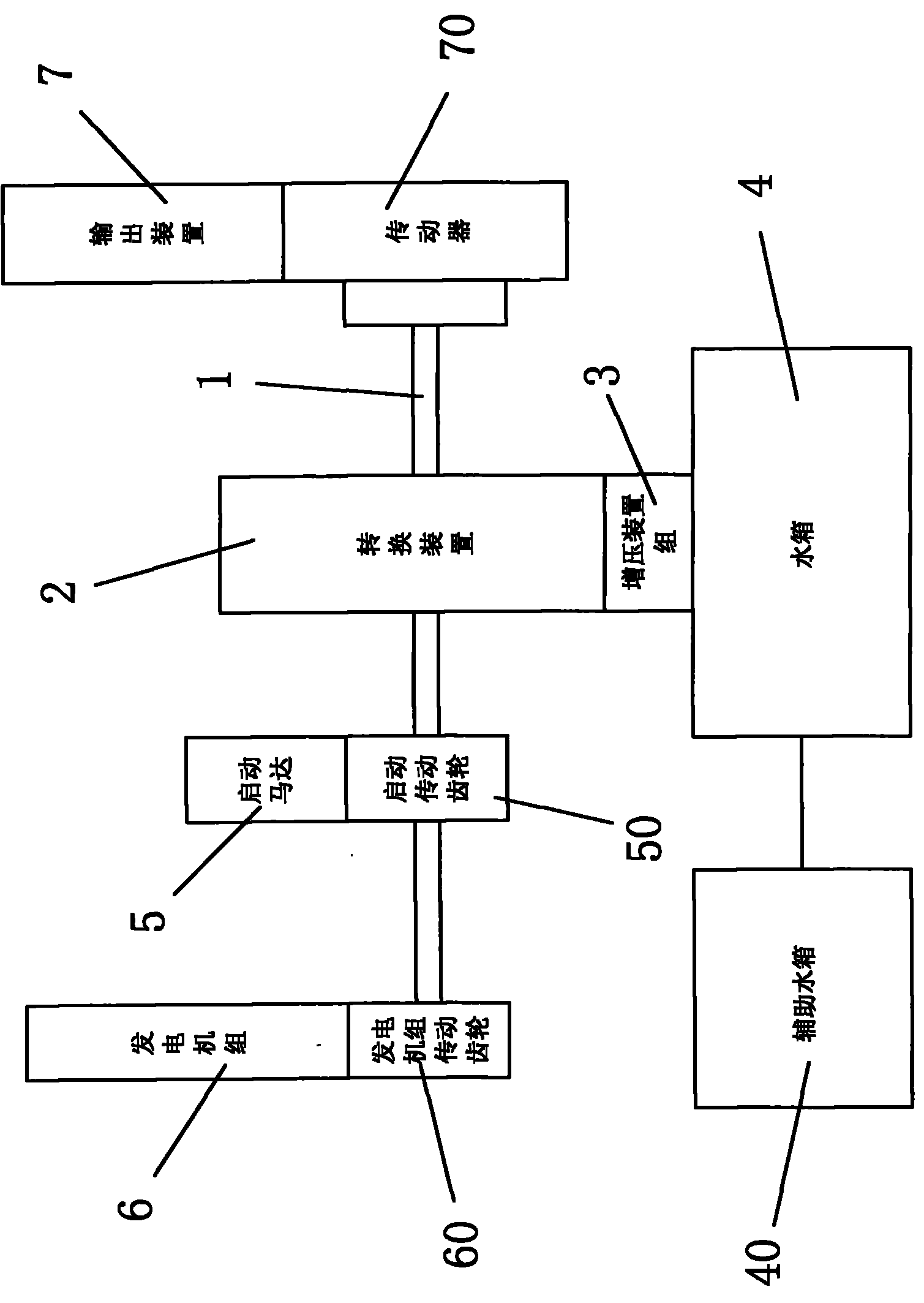

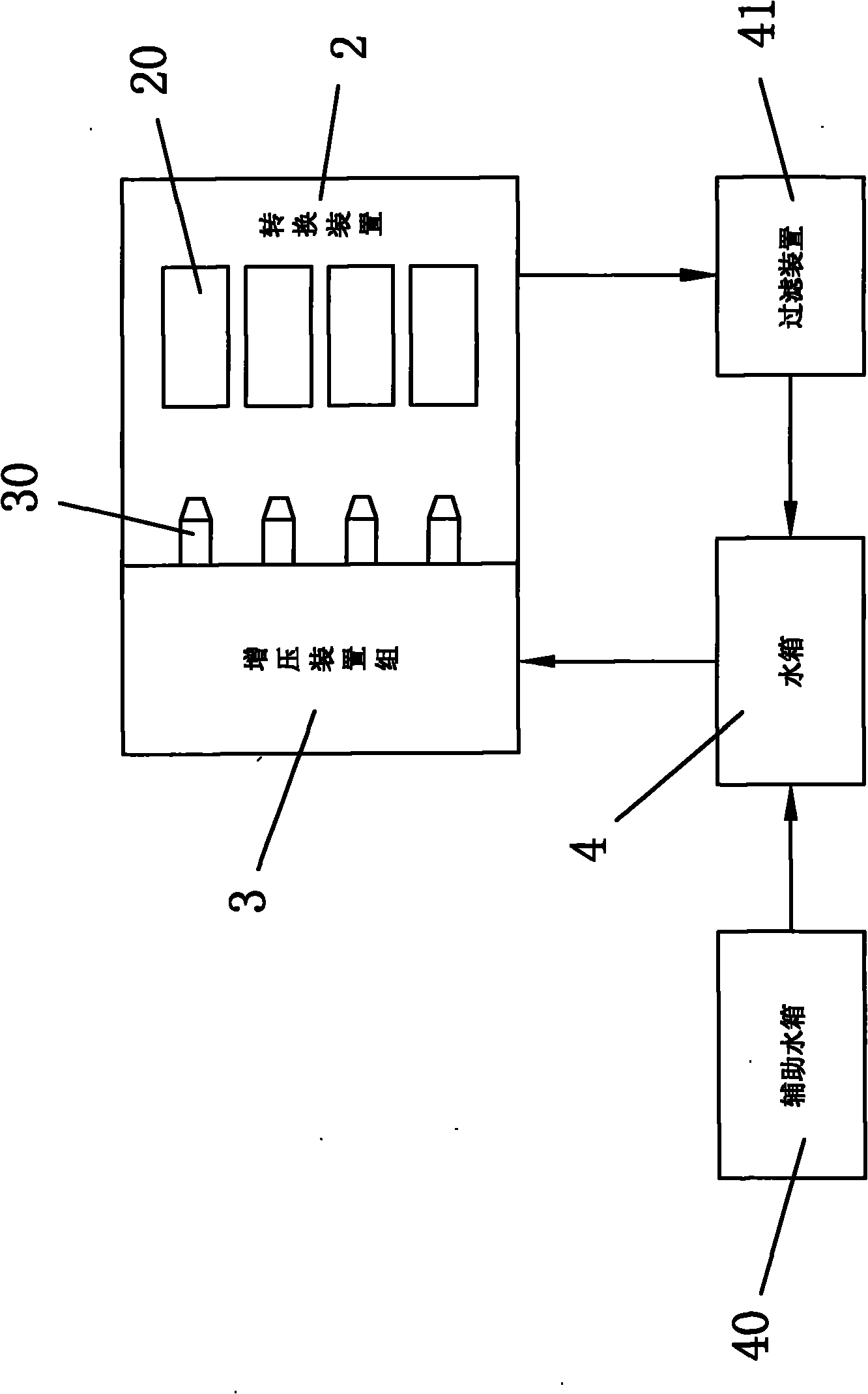

[0033] The present invention provides a driving method of a hydraulic pressure transmission engine, which includes the following steps:

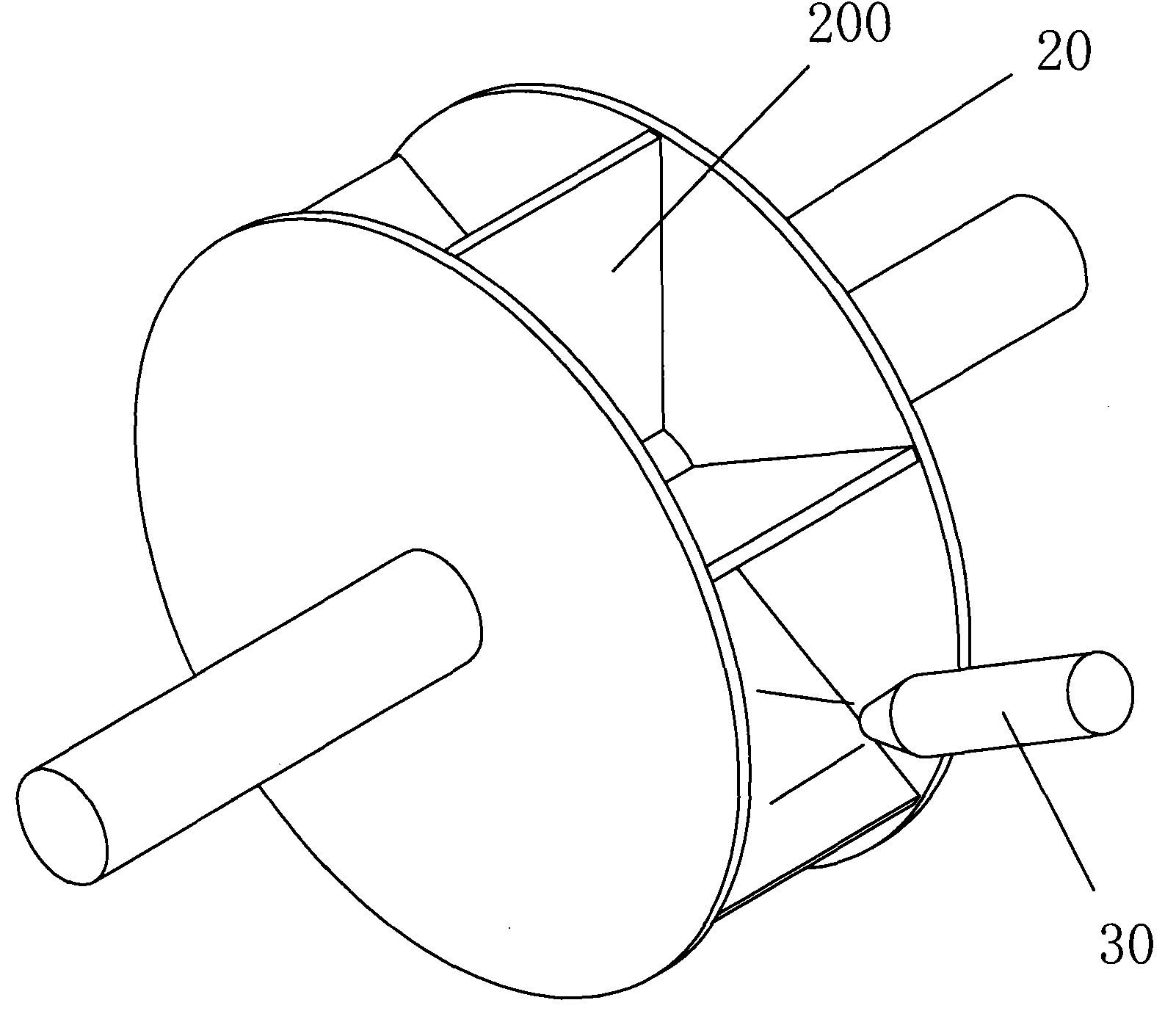

[0034] A. Pressurize the liquid into one of high-pressure liquid or ultra-high-pressure liquid, and then spray the pressurized liquid into a conversion device. For example, for the general industry, if the liquid pressure exceeds 200psi, it can be regarded as high pressure A liquid, if the pressure of the liquid exceeds 20,000 to 30,000 psi or more, it is an ultra-high pressure liquid.

[0035] B. The conversion device converts the pressure of the injected pressurized liquid into power and outputs it.

[0036] C. The power can drive a device equipped with a hydraulic pressure trans...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com