Liquid Line Evacuation Antifreeze

A technology of antifreeze device and liquid pipeline, which is applied in the direction of valve device, heating device, solar heat device, etc., to achieve the effect of reliable operation, convenient and practical control, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

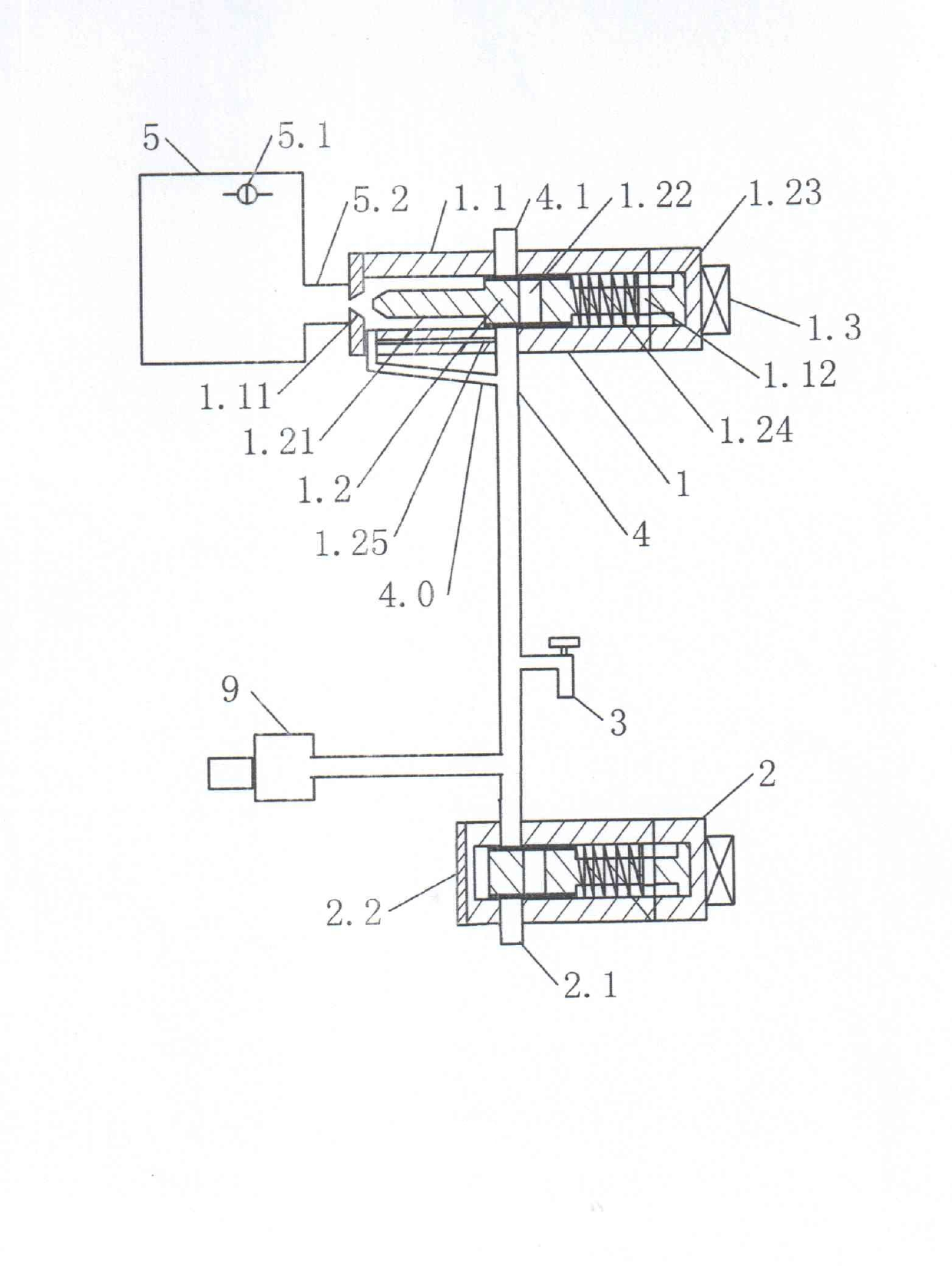

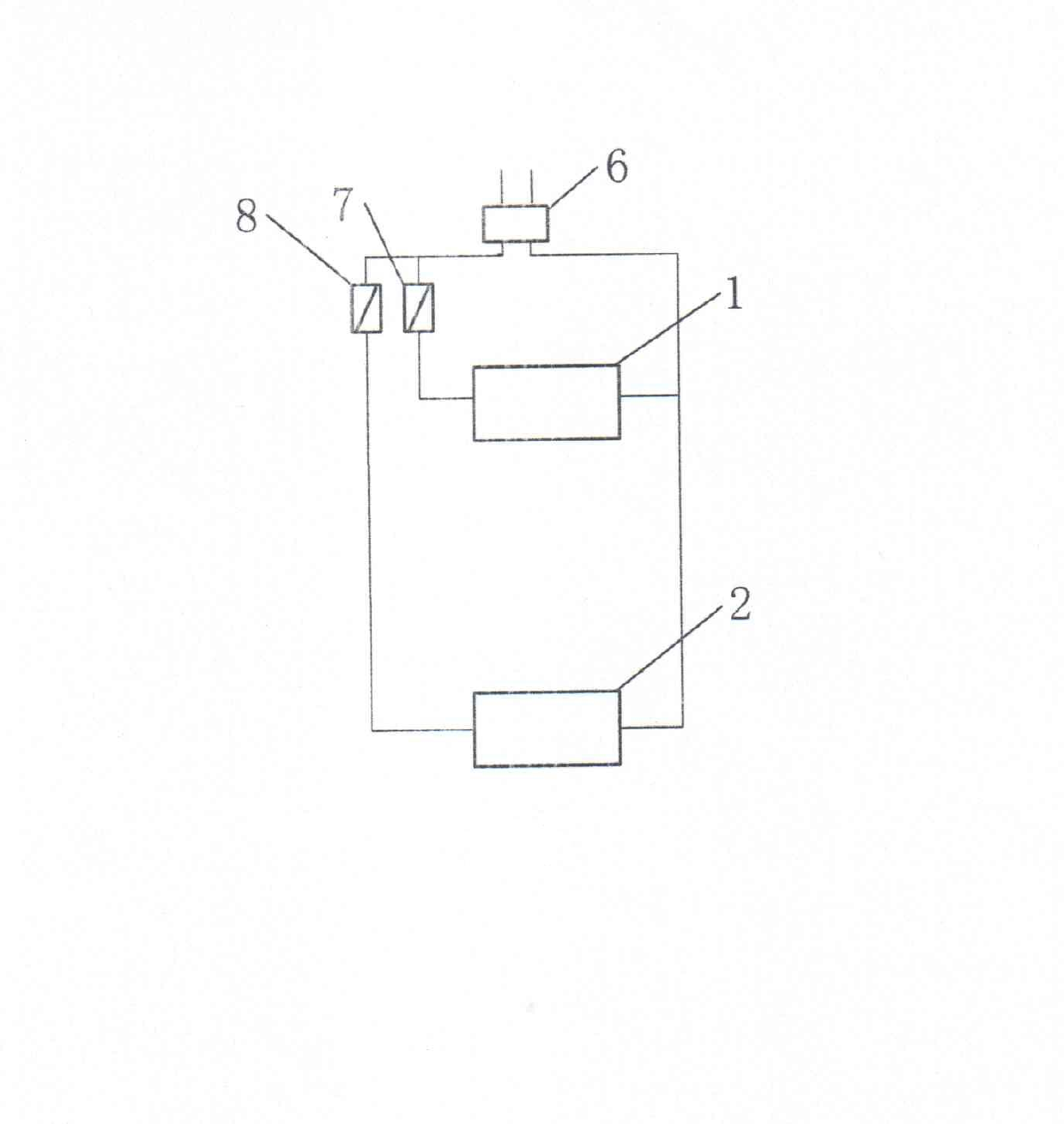

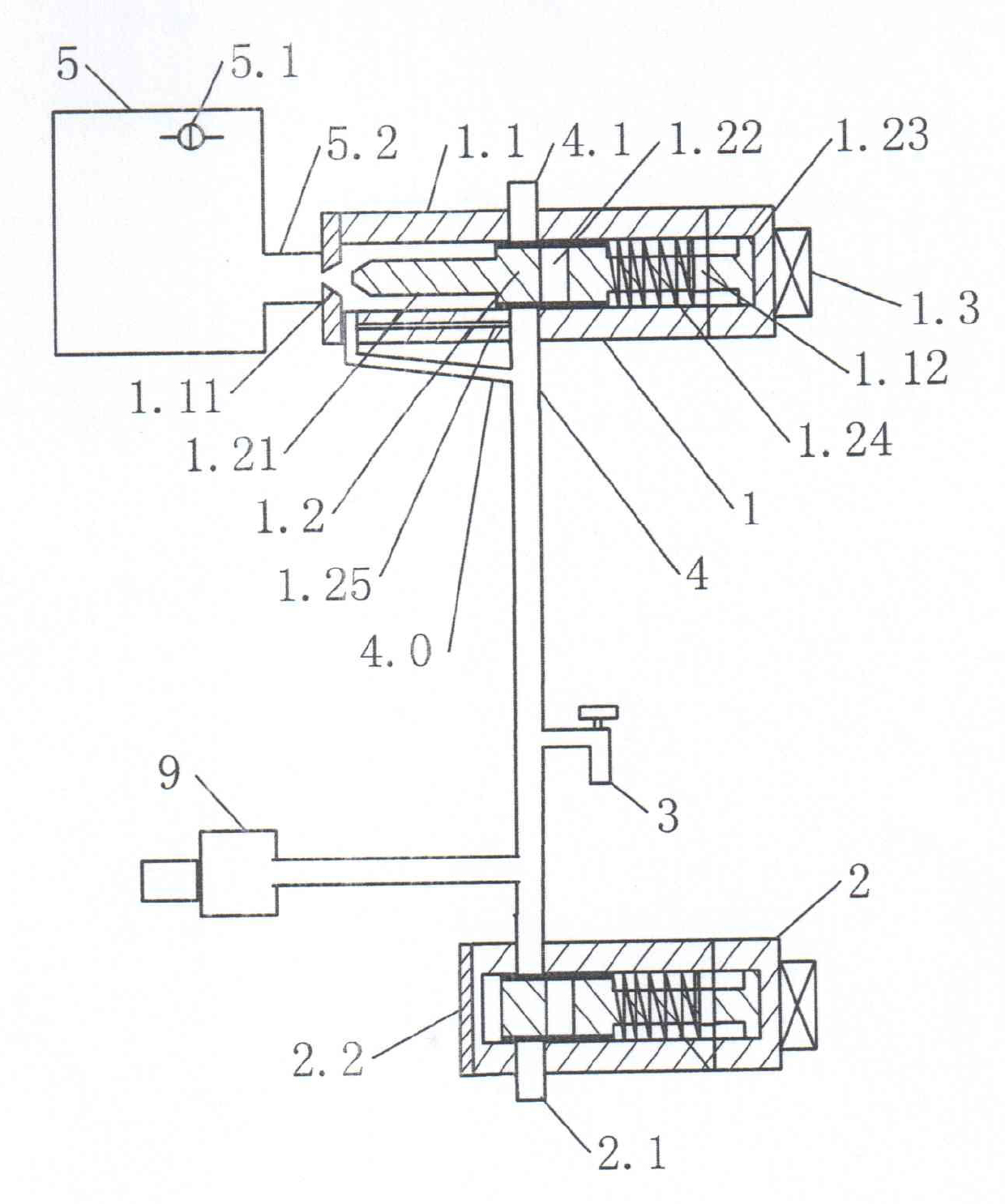

[0013] according to figure 1 As shown, the upper end of the water pipe is connected with a water injection and discharge solenoid valve 1, one side of which is connected to the water container 5 through a connecting pipe 5.2, a water level sensor switch 5.1 is installed in the water container, and the water injection and discharge solenoid valve is installed at the lower end through a water pipe 4. Water discharge solenoid valve 2 is arranged, and water discharge nozzle 3 is installed on the water pipe, and water supply solenoid valve 9 is installed by running water pipe on the water pipe between the water discharge solenoid valve and the water filling water discharge solenoid valve.

[0014] The structure of the water injection and discharge solenoid valve is: the valve body 1.1 of the water injection and discharge solenoid valve is a tubular structure, a valve seat 1.11 is arranged at the connecting pipe end, an electromagnetic driver 1.3 is installed at the other end of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com