A wiring structure of an induction layer

A wiring structure and sensing layer technology, which is applied in the field of wiring structure of a single-layer sensing layer, can solve the problems affecting the linearity and poor matching of the touch screen, and achieve the effect of improving linearity and good matching

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

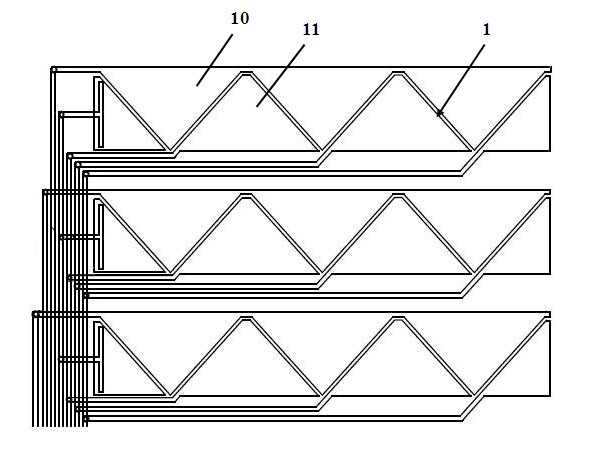

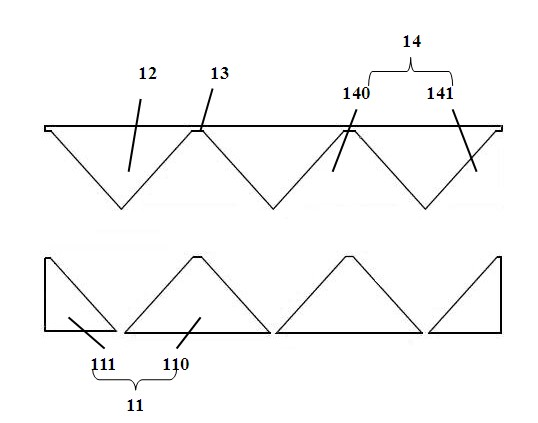

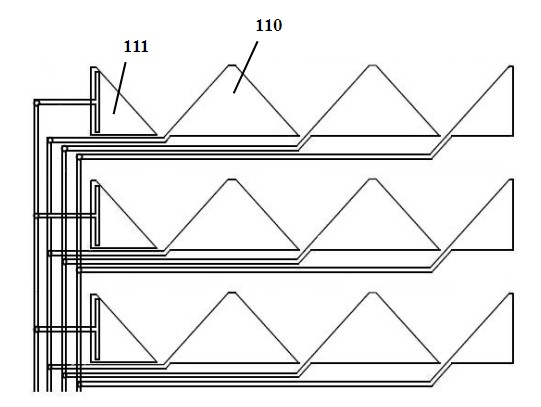

[0012] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

[0013] Please refer to figure 1 and figure 2 , the wiring structure of the sensing layer involved in the present invention, the sensing layer includes a plurality of touch electrode groups 1 arranged vertically, each of the touch electrode groups 1 includes a first touch electrode 10 and a plurality of second touch electrodes The electrodes 11, the first touch electrodes 10 and the second touch electrodes 11 are led out through wires. The first touch electrode 10 includes a plurality of fingers 12 , a main body 13 connecting the fingers and a plurality of notches 14 arranged laterally, and the second touch electrode 11 extends into the notches 14 . The notch 14 includes a middle notch 140 and an edge notch 141 , the edge notch 141 is located on both sides of the middle notch 140 , and the middle notch 140 is formed between two adjacent fingers ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com