Live working insulator replacement tool for self-locking conductors with rear tension clamps

A technology of tension-resistant clamps and live work, which is applied in the direction of overhead lines/cable equipment, etc., can solve the problems of broken transmission lines, low operation safety, and no value, and achieves low manufacturing costs, convenient operation, and easy promotion and application Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

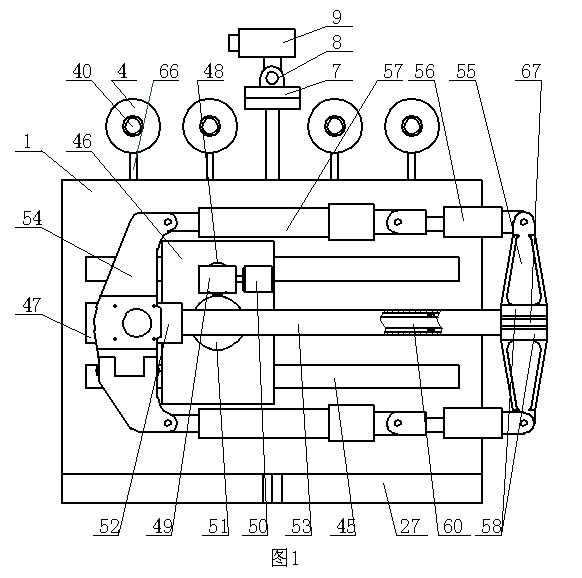

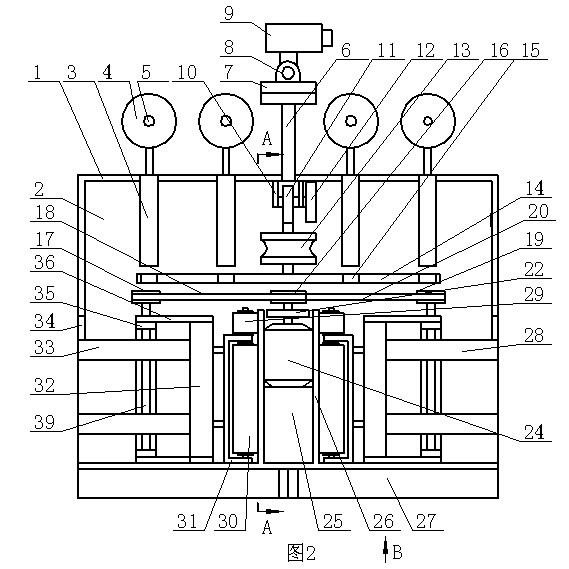

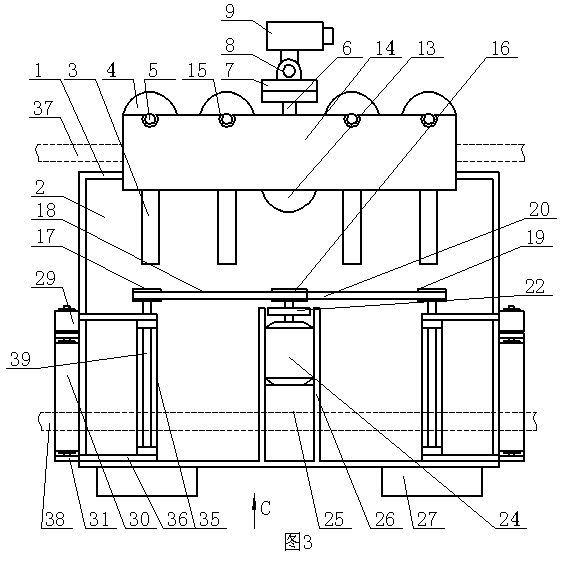

[0009] The live working insulator replacement tool for the self-locking wire of the post-tension clamp according to the present invention, such as figure 2 As shown, it includes a housing 1, an inner chamber 2 is provided in the housing 1, four first buffer rods 3 are fixedly installed on the upper part of the inner chamber 2, and the first guide rod 66 of each first buffer rod 3 extends out of the housing. 1 travel motor 40 is installed outside, and travel sheave 4 is installed on the output shaft of travel motor 40. For convenience, the replacement insulator tool is suspended on the overhead line by the walking sheave 4, such as Figure 5 and Figure 6 As shown, all the running sheaves 4 are located at the front top of the housing 1. Such as figure 2 As shown, the lower part of the inner cavity 2 is symmetrically installed with two barrier-crossing brackets 28 with the central axis of the inner cavity 2 as the midline. Such as figure 2 and Figure 6 Shown, each stra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com