A machining method for shaft keyway

A processing method and keyway technology, applied in metal processing equipment, metal processing mechanical parts, manufacturing tools, etc., can solve the problem of difficult to ensure the accuracy of the keyway position, and achieve the effect of simple structure, cost saving, and guaranteed shape and position tolerance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be described in detail below with reference to the drawings and specific embodiments.

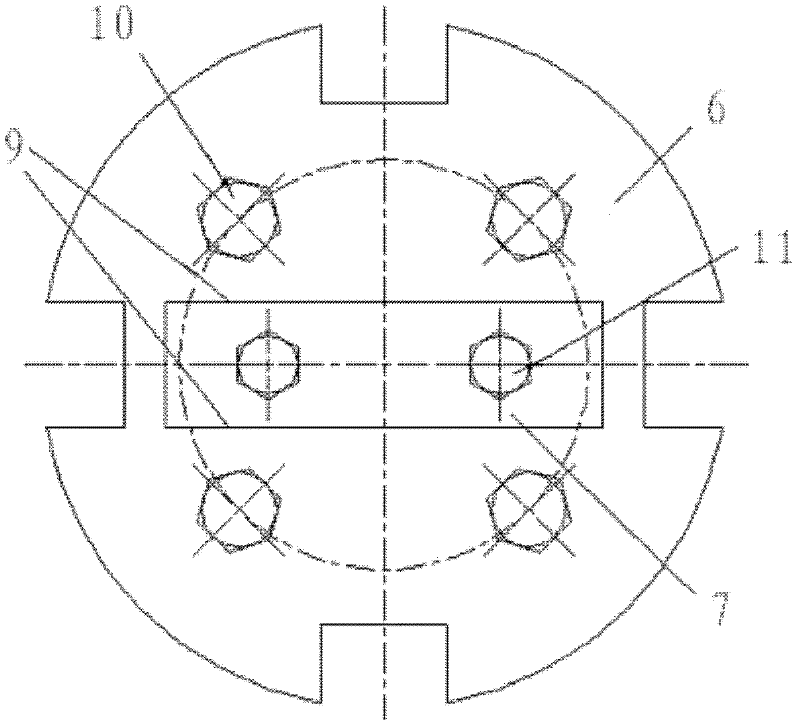

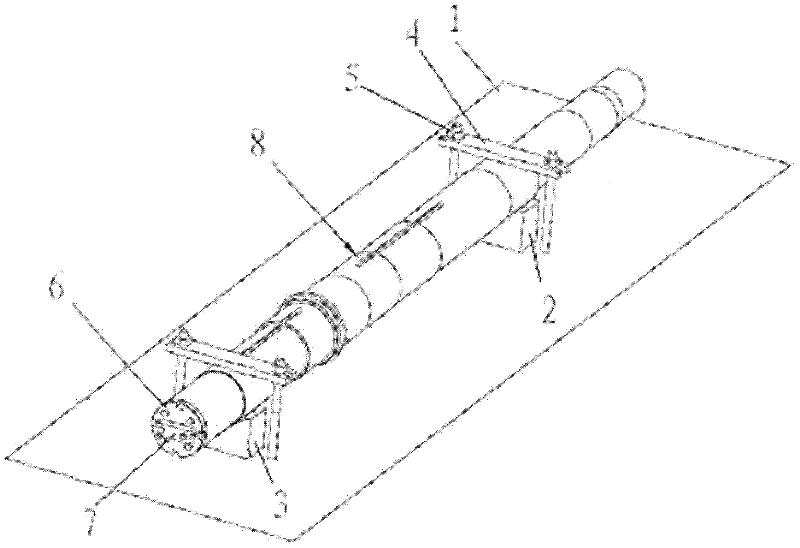

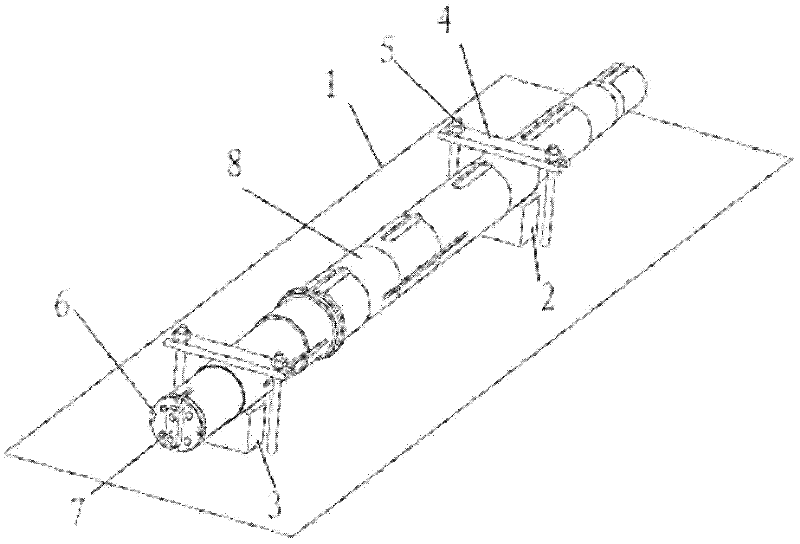

[0019] Such as figure 1 , Is the structural diagram of the connecting plate 6 and the alignment block 7 used in the method of processing the shaft keyway of the present invention. The connecting plate 6 is provided with four bolts and one mounting hole, and the four screws and one mounting hole are evenly arranged on the same circumference On the line, the four screws, one mounting hole, and the four bolts one 10 provided on the shaft end of the workpiece shaft 8, ensure the concentricity of the connecting disk 6 and the workpiece shaft 8; the connecting disk 6 faces the upper edge of the alignment block 7 Two bolt two 11 are provided diametrically symmetrically, two bolt two mounting holes are symmetrically opened on the longitudinal center line of the aligning block 7, and the two bolt two mounting holes are correspondingly set with the two bolt two 11 on the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com