A forced unloading drill bucket

A drilling bucket and soil drilling technology, which is applied to earth-moving drilling, drill bits, drilling equipment, etc., can solve problems such as unfavorable soil unloading, affecting the use of drilling buckets, and failing to overcome disadvantages, so as to improve reliability, avoid damage, impact force, etc. smooth effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

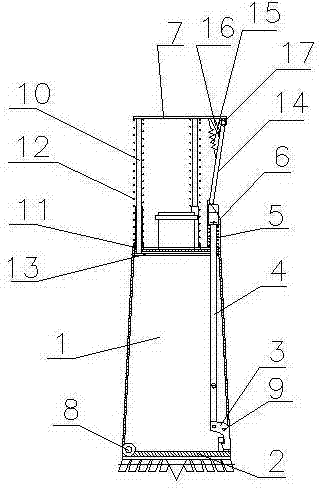

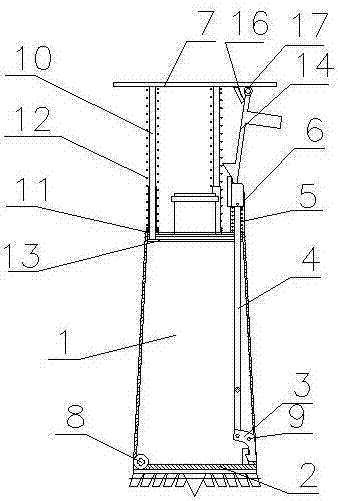

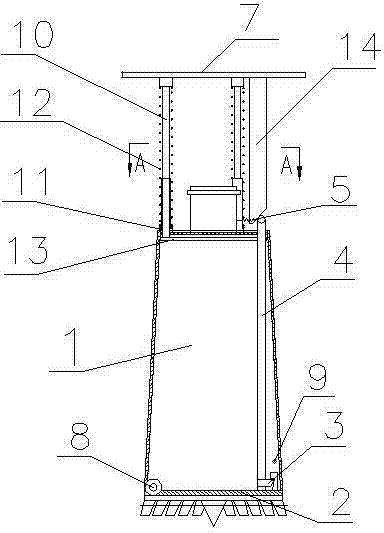

[0020] Below in conjunction with accompanying drawing, the present invention is described in further detail:

[0021] exist figure 1 In the embodiment of the forced soil unloading drill bucket shown, the drill bucket includes a drill bucket body 1, a door opening mechanism, a soil unloading device, and a bottom door 2 of the drill bucket. The bottom door 2 of the drill bucket is located at the lower port of the drill bucket body 1. One end of the bottom door 2 is provided with a lock catch, which is matched with the bucket door hook 3 of the door opening mechanism. The other end of the bottom door 2 of the drilling bucket is hinged with the bucket body 1 by the bucket door hinge 8. The bulldozer plate 13 in the inner cavity of the bucket body 1, the push plate 7 located on the upper part of the drill bucket body 1, and the bulldozer pressure rods 10 connected to the bulldozer plate 13 and the push plate 7 at both ends respectively, the bulldozer pressure rod 10 passes through ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com