Oscillating mechanism of tower-type fan

A fan and tower-type technology, applied in the field of shaking head mechanism, can solve the problems of power cord damage, low safety, fire, etc., and achieve the effect of reducing internal friction damage, eliminating cross-winding, and simple assembly structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The patent of the present invention will be further described below in conjunction with the accompanying drawings and examples of implementation.

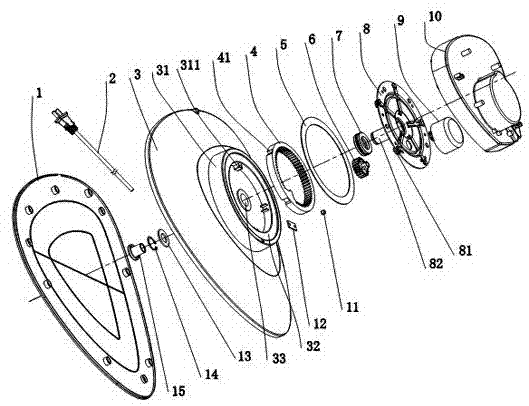

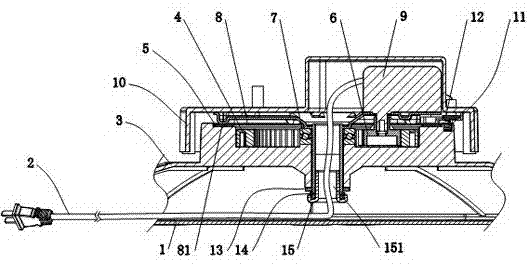

[0016] like figure 1 , 2 As shown, the present invention is an oscillating mechanism of a tower fan, which includes a support plate 10 that drives the body of the tower fan to rotate, a fixed plate 8 installed on the support plate 10, a synchronous motor 9 installed on the fixed plate 8 and Hall sensor 12, driving gear 6 installed on the extension shaft of synchronous motor 9, driven gear 4 meshed with driving gear 6, base 3 for installing driven gear 4, magnet 11 installed in the groove of base 3 And the bottom plate 1 installed on the base 3; the fixed plate 8 is provided with a hollow shaft 82, the center of the base 3 is provided with a fixed hole 33, the lower end of the hollow shaft 82 is inserted into the fixed hole 33 and Axial positioning; the Hall sensor 12 is installed on the support plate 10 and cooperates with...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com