Capacitor gummed paper winding and cutting device

An adhesive tape and capacitor technology, applied in capacitors, capacitor manufacturing, circuits, etc., can solve problems such as being unable to keep up with the production speed, affecting the quality of products shipped, and misapplying adhesive tapes, reducing manual labor and avoiding leakage. , the effect of improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

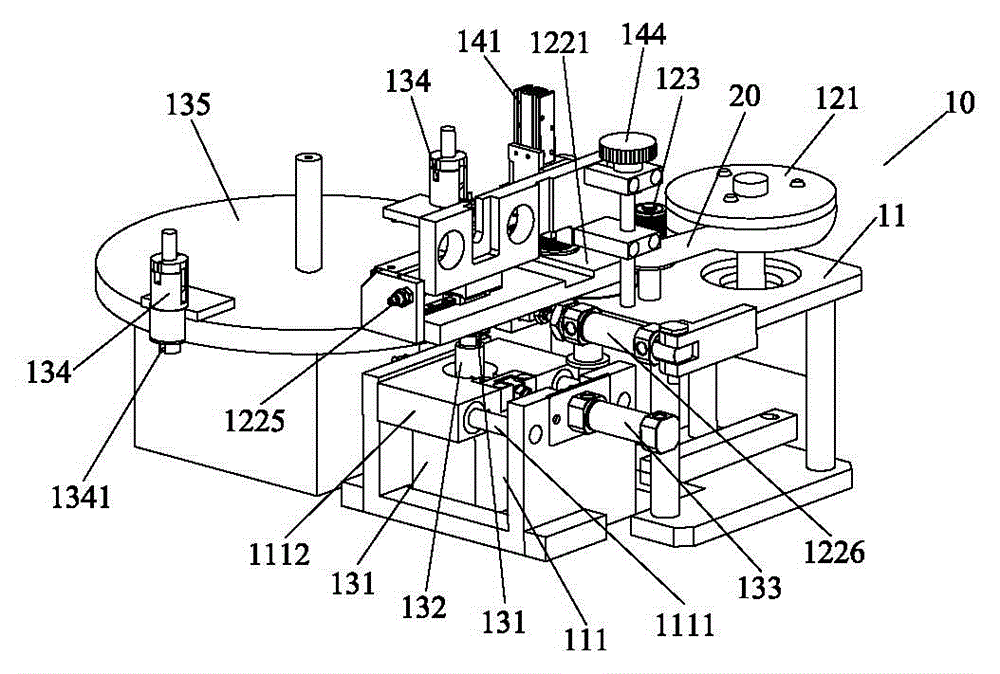

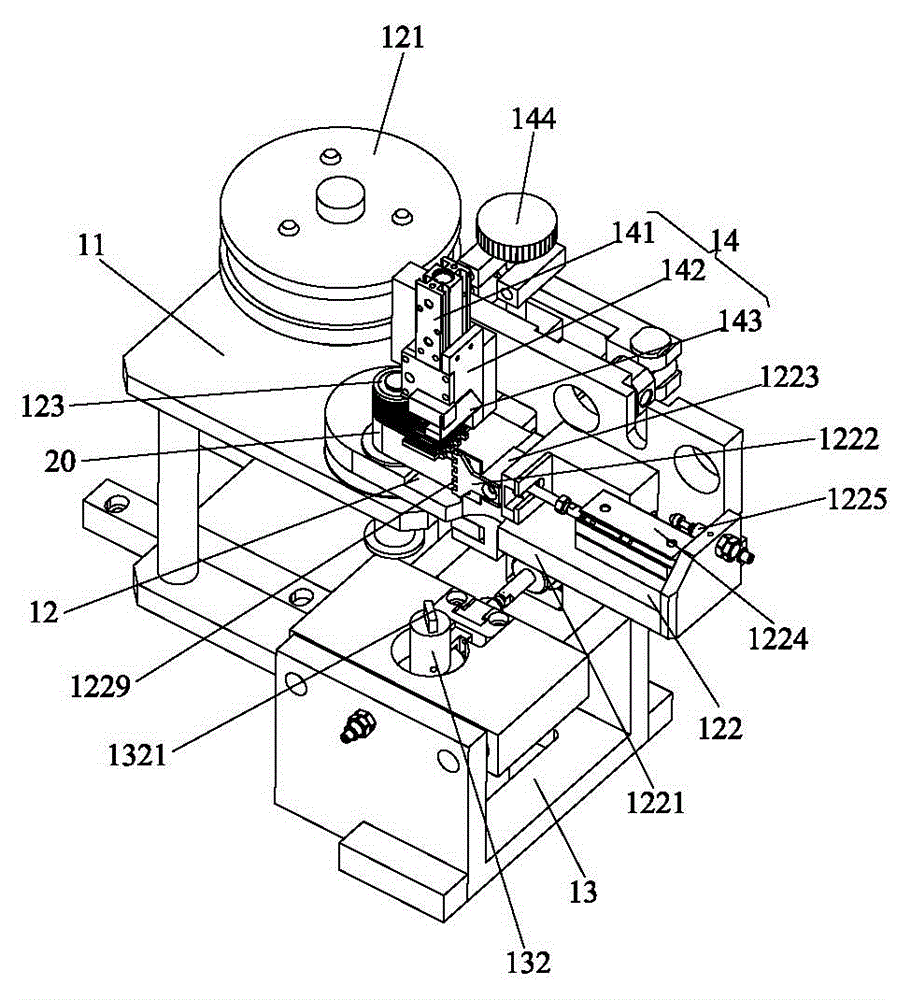

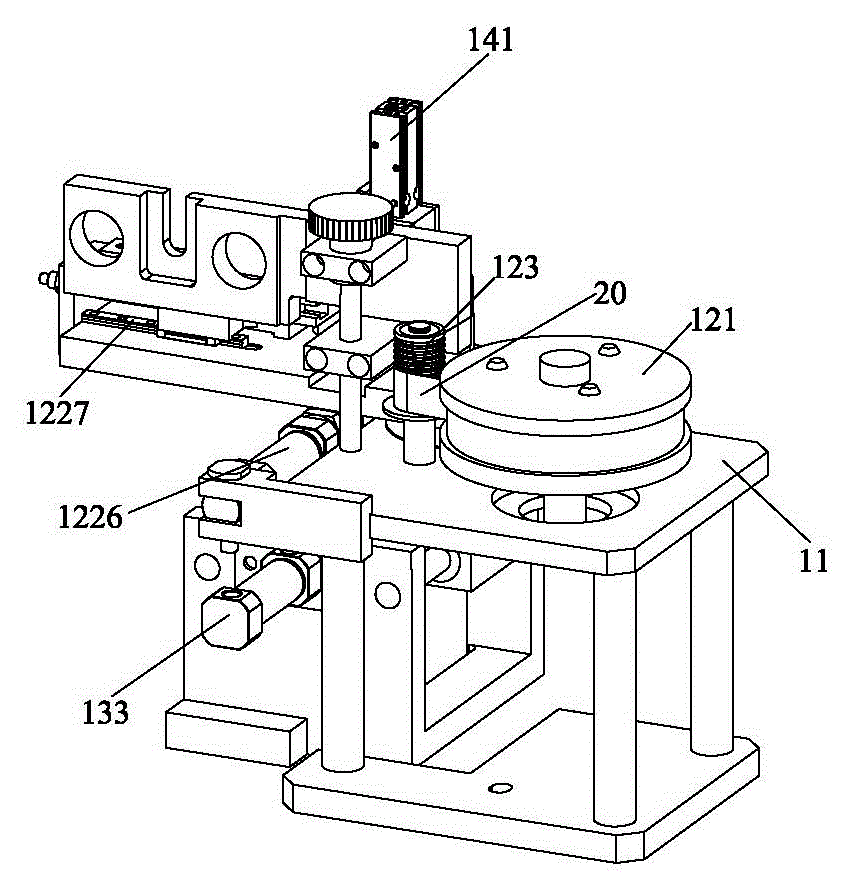

[0035] The present invention as Figure 1 to Figure 4 As shown, a capacitor-coated paper cutting device includes a base 11, a tape conveying mechanism 12 installed on the base 11, a tape winding mechanism 13 and a tape cutting mechanism 14, wherein:

[0036] The tape conveying mechanism 12 includes a tape tray 121, a tape pulling assembly 122 and a plurality of tensioning wheels 123 for tensioning the tape 20 to be wound. The tape tray 121 is rotatably mounted on the base 11, The glued paper assembly 122 includes a substrate 1221, a laminated paperboard 1222 mounted on the substrate 1221, a laminated paper cylinder 1223, a glued paper cylinder 1224, a distance sensor 1225 for sensing the pulling distance, and a distance sensor 1225 for pushing the substrate 1221 to rotate to The indexing cylinder 1226 close to the above-mentioned capacitor fixing seat 134, the base plate 1221 is provided with a guide rail 1227, and a side seat 1228 is slidably installed on the guide rail 1227,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com