Screw for fixing resonant bar, cavity filter and communication equipment

A technology of cavity filter and resonant rod, which is applied in the direction of screws, mechanical equipment, waveguide devices, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

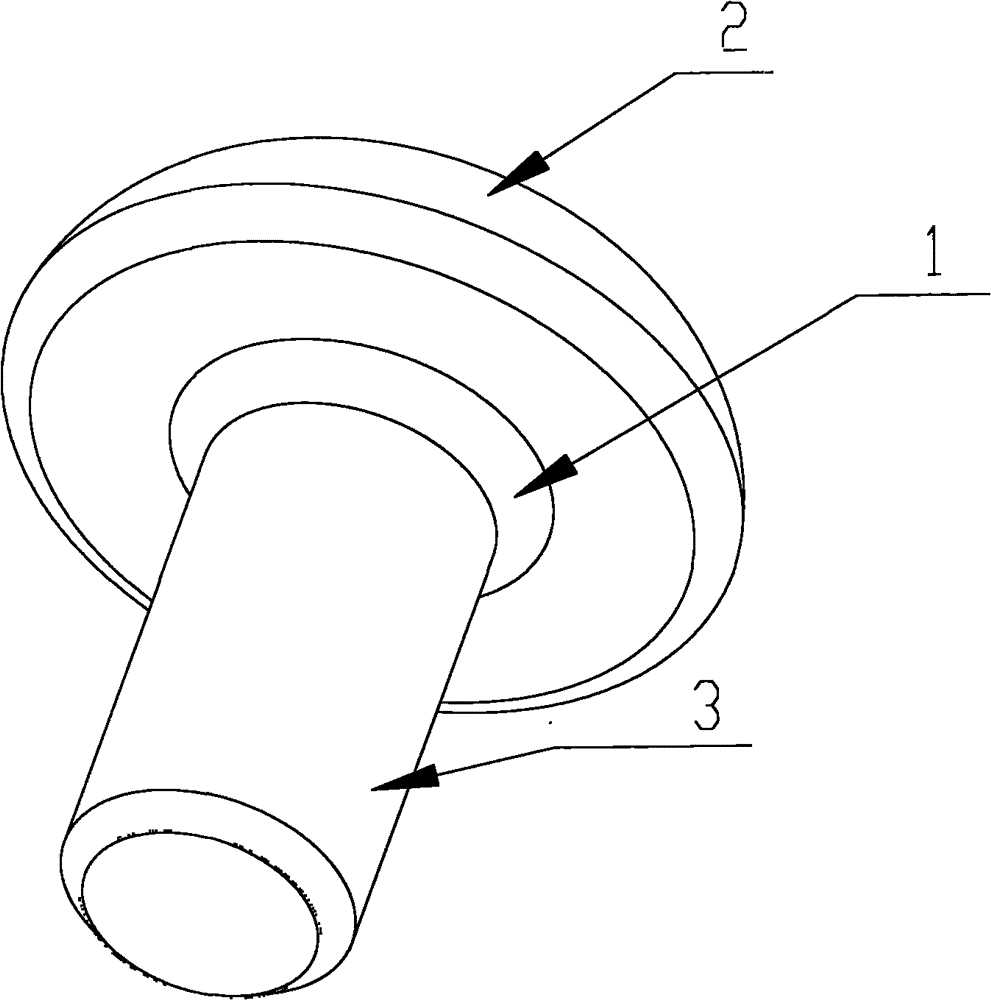

[0026] Embodiment one, as Figure 4 with Figure 5 As shown, a screw for fixing a resonant rod has a shank 23 with at least partial threads, one end of the shank is a screw head 21, and a transition zone 22 is between the screw head 21 and the shank 23 , there is an annular groove 24 around the transition zone 22 with the rod portion 23 as the center, the transition zone 22 is sunk in the groove 24, the depth of the groove is greater than the height of the transition zone, and the fixed resonance When the rod is connected, the top surface 25 of the groove exerts pressure on the bottom of the resonant rod to fix the resonant rod. The screw head 21 may be round, square or other shapes, the shape of the screw head is not enough to limit the present invention.

[0027] The end of the shank 23 of the screw in contact with the bottom surface of the screw head is a fixed end, and the end far away from the screw head is a free end. There are threads on the screw shank, and the dist...

Embodiment 2

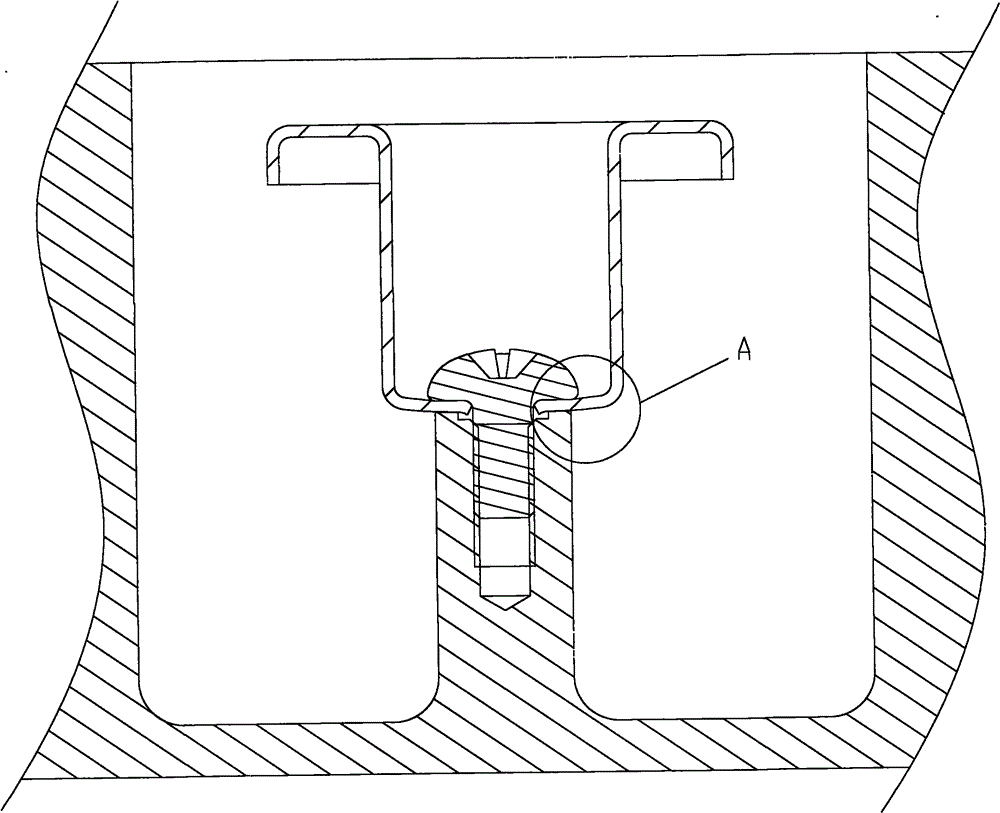

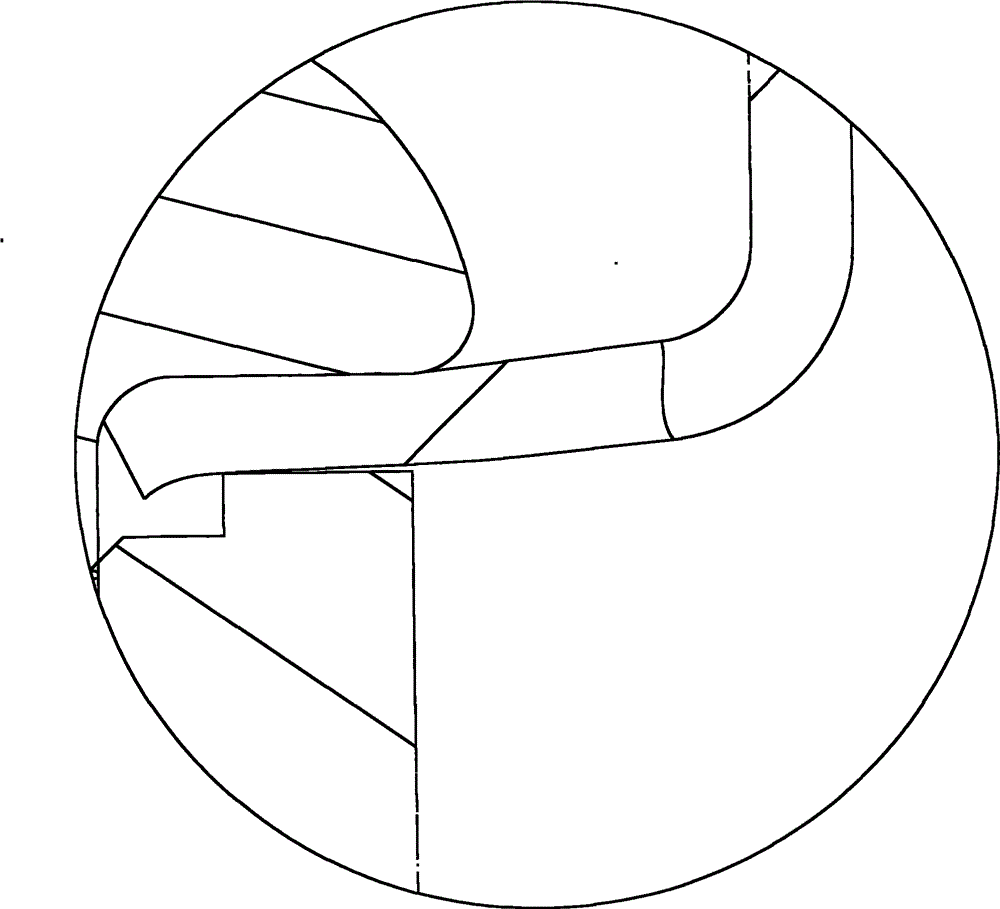

[0032] Embodiment 2. A cavity filter provided by this embodiment, such as Image 6 with Figure 7Shown are the sectional view and partial enlarged view of the cavity filter provided by this implementation, including a cavity 31, a resonant tube 32 and a screw 33, a support seat 34 is provided in the cavity, and a support seat 34 is provided on the bottom surface of the resonant tube 32. There is a through hole, and the screw passes through the through hole to fix the resonant tube 32 on the support seat 34 in the cavity 31. The screw 33 has a shank with at least a part of thread, and one end of the shank is a screw head There is a transition area between the screw head and the shank, and there is an annular groove around the transition area with the shank as the center, the transition area is sunk in the groove, and the groove depth is greater than the When fixing the resonant rod, the top of the groove exerts pressure on the bottom of the resonant rod to fix the resonant rod...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com