Fire cover for gas cooker, burner and gas cooker with the same fire cover

A gas stove and fire cover technology, which is applied to gas fuel burners, burners, combustion methods, etc., can solve the problems of insufficient distribution of fire holes in the inner side, no effective solution to heating, insufficient heating of the bottom of the pot, etc. The effect of uniform phenomenon, saving cooking time and material saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] In order to make the object, scheme and beneficial effect of the present invention more clear, the present invention will be further described below in conjunction with the accompanying drawings and preferred embodiments.

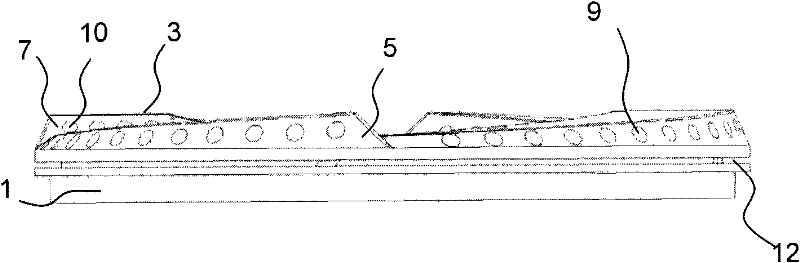

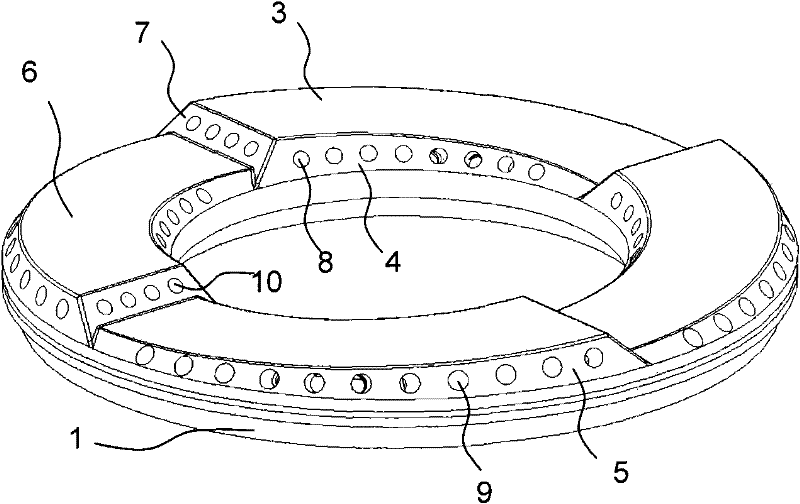

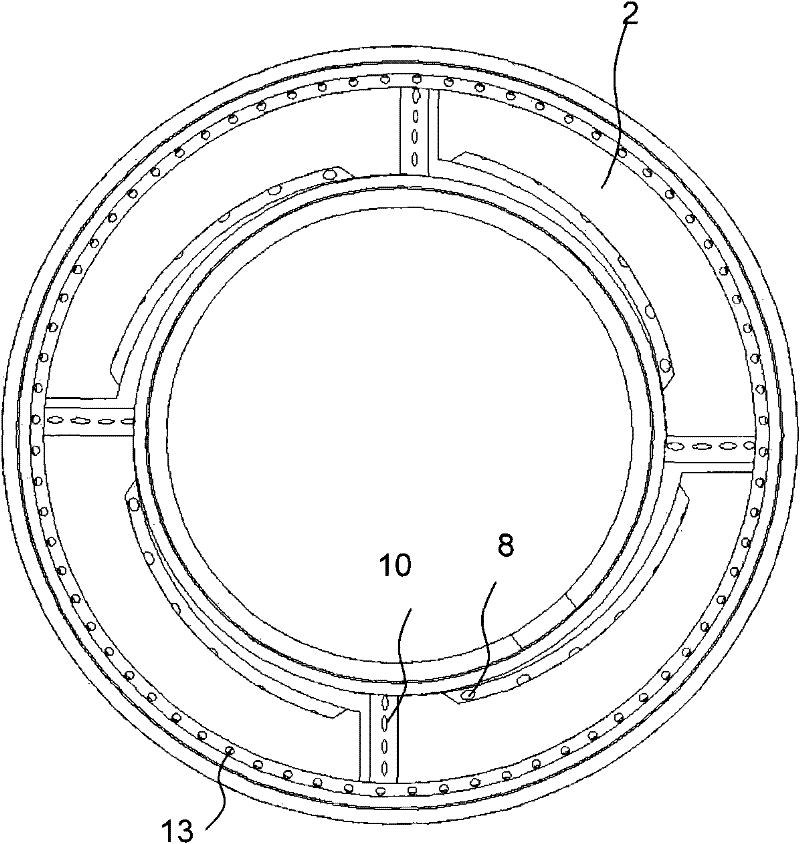

[0041] An embodiment of a fire cover for a gas stove proposed by the present invention Figures 1 to 5 As shown, the burner cover for a gas stove includes a substantially ring-shaped cover body 1 , and the lower surface of the cover body 1 is concave to form an air-containing cavity 2 . Four bosses 3 are arranged on the upper surface of the cover body 1 , and the bosses 3 are hollow structures, and the hollow parts communicate directly with the air chamber 2 . The heights of the four bosses 3 increase gradually along the same direction of the circumference of the cover body 1, that is, the thickness of the bosses 3 increases uniformly, that is, the upper surface 6 of the bosses 3 generally rises obliquely along a fixed angle. Furthermore, an angle θ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com