Efficient antifreeze water source heat pump device

A water source heat pump and water pump technology, applied in the field of heat exchange, can solve the problems of freezing damage of heat pump unit coils, equipment damage, affecting the use efficiency of water source heat pumps, etc., and achieve the effects of increasing heat, improving efficiency, and improving the protection temperature of water outlet.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

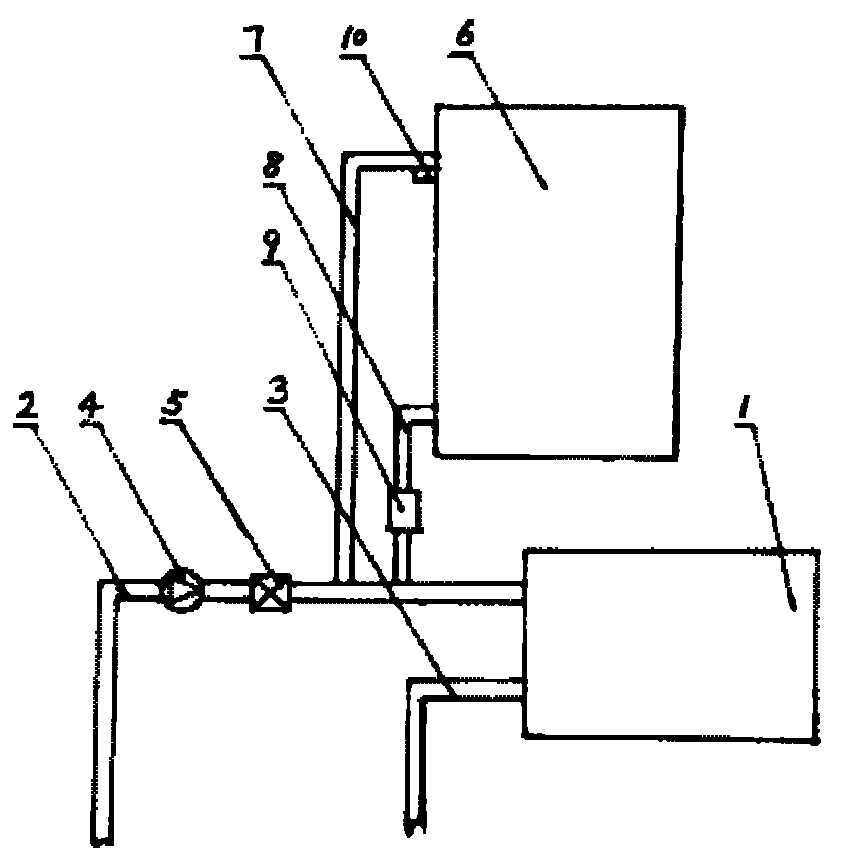

[0010] The present invention is composed of a heat pump unit 1, a water inlet pipe 2, a drain pipe 3 and a water pump 4. A check valve 5 is installed on the water inlet pipe 2 between the water pump 4 and the heat pump unit 1, and a high-level water tank 6 is installed above the heat pump unit 1. The upper water tank 6 is equipped with an upper water pipe 7 and a lower water pipe 8. The other ends of the upper water pipe 7 and the lower water pipe 8 are connected to the inlet pipe 2 between the one-way valve 5 and the heat pump unit 1, and the lower water pipe 8 is equipped with an unconventional The solenoid valve 9 is equipped with an automatic control valve 10 at the entrance of the upper water pipe 7 of the high-level water tank 6.

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap