Water cannon mud bag and its method for sealing coal mine blasthole

A technology of popping mud and bag body, which can be used in blasting and other directions to solve the problems of large dust and harmful gases from gun smoke.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

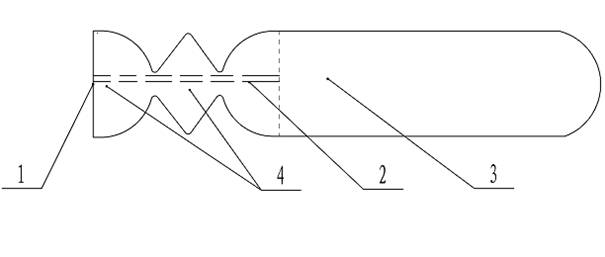

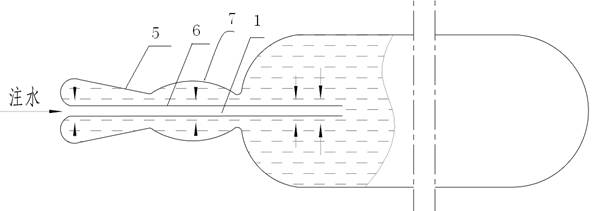

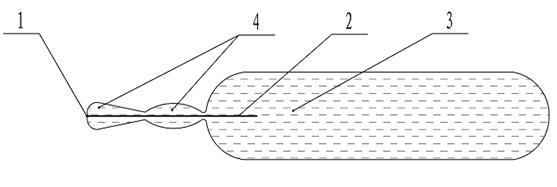

[0028] refer to figure 1 , 2 , 3, a kind of mine foam mud bag, comprise bag body 3 and the water inlet nozzle 7 that soft material is made, water inlet nozzle 7 reversely stretches in, when bag body is filled with liquid, because the pressure of the liquid in the bag body is greater than Outside atmospheric pressure, the water inlet nozzle 7 wall surfaces are pressed and fitted together to close the water inlet nozzle.

[0029] In this embodiment, the water inlet 7 is composed of inner and outer layers, the outer layer 5 is connected to the bag body at the beginning, the outer layer 5 is connected to the end of the inner layer 6, and the inner layer 6 is deep inside the bag body, and the inner layer 6 can be attached under pressure combine.

[0030] The water inlet 7 includes a water inlet 1 communicating with the bag body and a pressure chamber 4 located on the periphery of the water inlet 1. The water inlet 7 can form a sealing port 2 under the action of liquid pressure. W...

Embodiment 2

[0042] Reference attached Figure 4 , The section of the water inlet nozzle 7 is rectangular, and the others are the same as in Embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com