Pump casing position detection method and inspection tool

A detection method and technology of position degree, applied in the direction of measurement device, mechanical device, mechanical measurement device, etc., can solve the problems of high requirements for inspection personnel and low efficiency of pump casing position degree, and achieve simple operation and low comprehensive detection cost. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

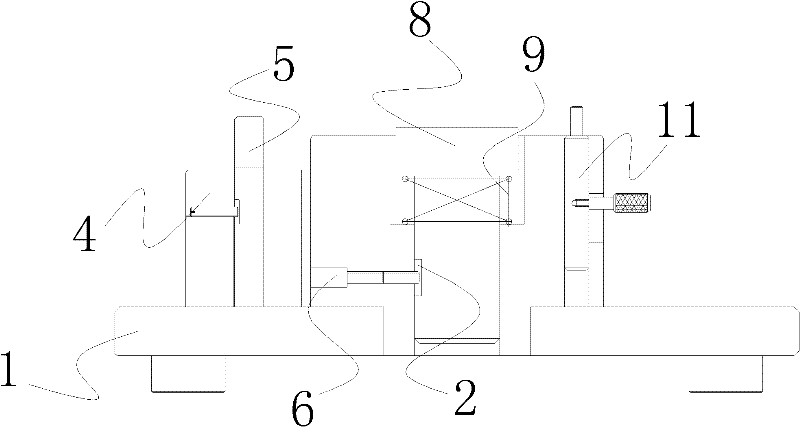

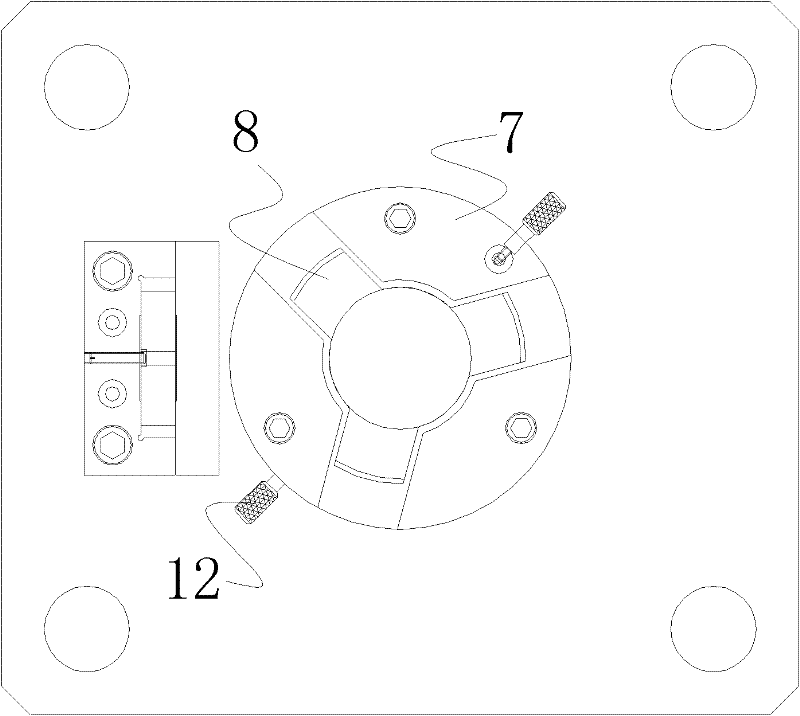

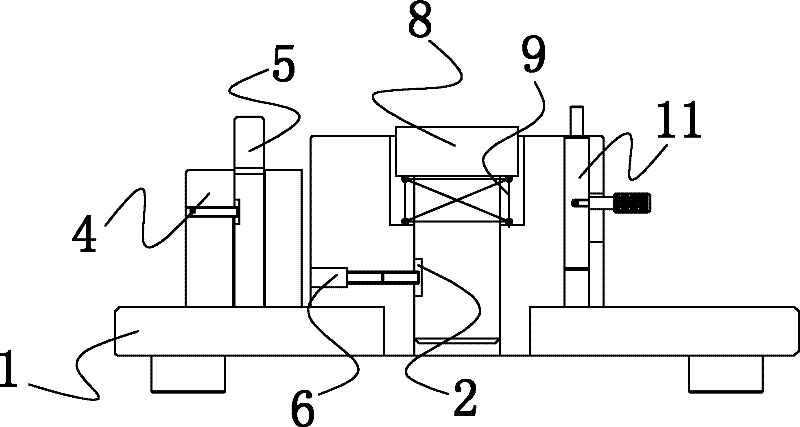

[0019] The present invention is described in detail below in conjunction with accompanying drawing, as figure 1 , figure 2 Shown:

[0020] The method for detecting the position of the pump casing includes the following steps:

[0021] 1] Snap the casing of the pump casing under test into the matching casing detection mechanism to complete the preliminary positioning and detection of the pump casing under test. If the casing can be snapped into the casing detection mechanism, the measured The inner diameter of the pump casing meets the requirements. If it cannot be stuck into the casing detection mechanism, the inner diameter of the pump casing under test does not meet the requirements;

[0022] 2] After step 1 is completed, perform angular positioning of the parts to detect whether the threaded holes and connecting pipes of the pump casing under test meet the requirements;

[0023] 2.1] After the angular positioning is completed, the position of the threaded hole of the te...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com