Automatic thickness gauge and automatic thickness measuring system

A thickness gauge, automatic technology, applied in the field of machinery, can solve the problems that the thickness of packaging materials cannot be accurately measured, the thickness measurement work cannot be carried out effectively, and the high sampling frequency cannot be met, so as to facilitate analysis and judgment, improve test efficiency, and compact structure Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

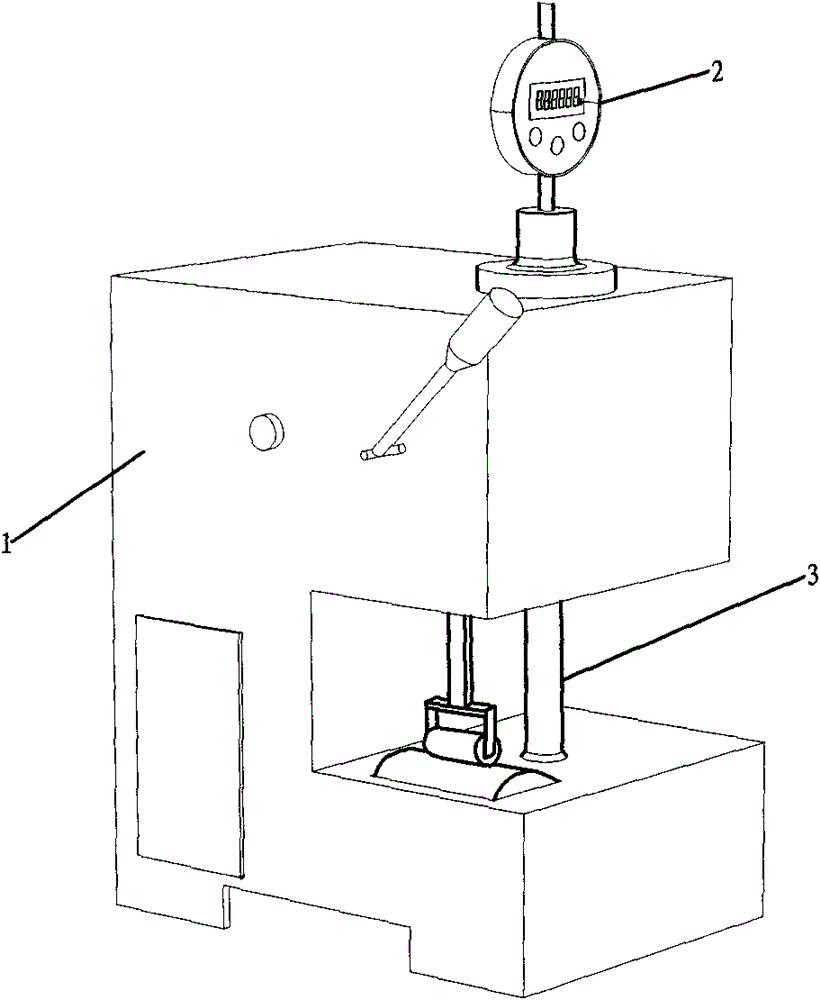

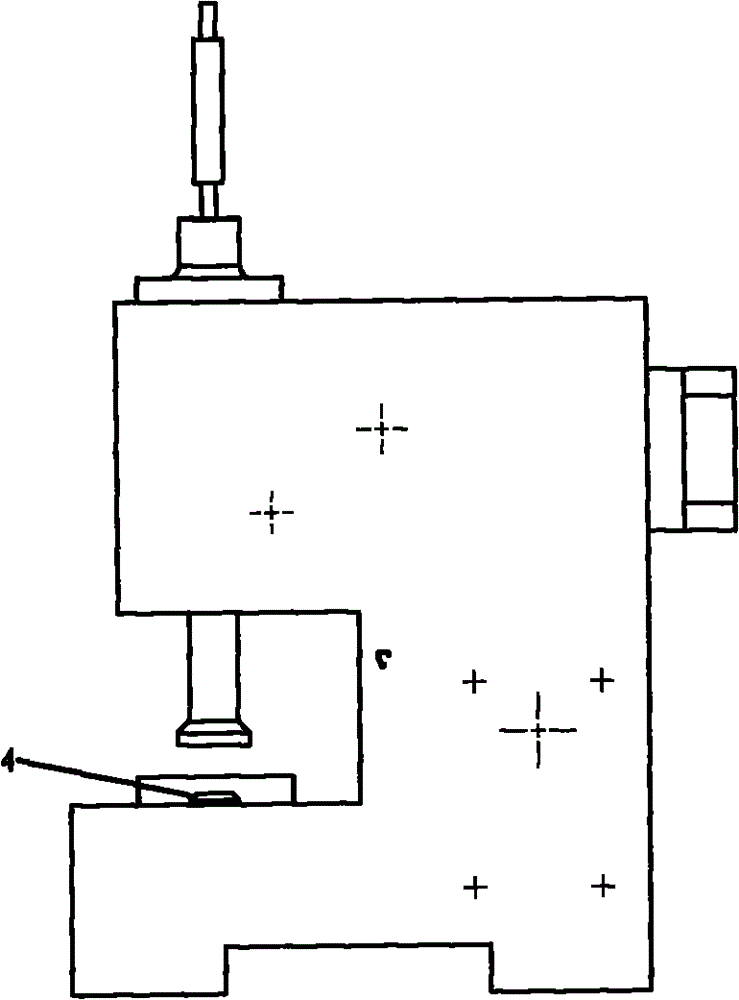

[0032] The invention will be described in further detail below in conjunction with the accompanying drawings and the embodiments thereof.

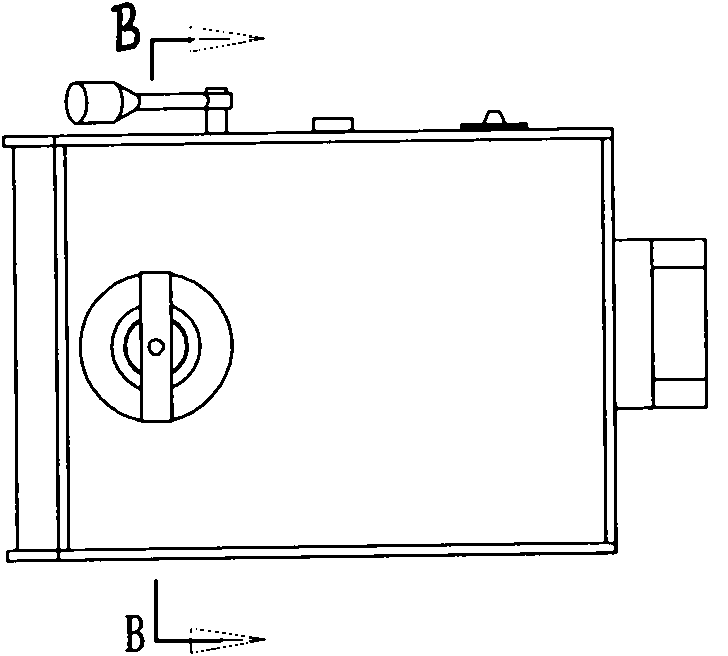

[0033] Refer to attached Figure 1-12 As shown, the present invention is an automatic thickness gauge, comprising a casing 1, an electronic dial indicator 2 is arranged in the casing 1, and the electronic dial indicator 2 is fixedly connected to the measuring rod 3; the measuring rod 3 is located in the casing 1 The position directly below is provided with a measuring platform 4; the control switch 5 of the electronic dial indicator 2 is provided in the casing 1;

[0034] A motor 6 is also fixed inside the casing 1, and three cams are fixed on the rotating shaft of the motor 6, including a measuring rod up and down movement cam 7, a signal cam 8 and a paper feeding movement cam 9; On one side, the signal cam 8 is located on the side of the control switch 5 of the electronic dial indicator 2, and the paper-feeding action cam 9 is located o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com