Radial sampling device for thermal simulating furnace

A sampling device, radiation-type technology, applied in the sampling device and other directions, can solve the problems of sample limitation, sample extraction, and small number of samples.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

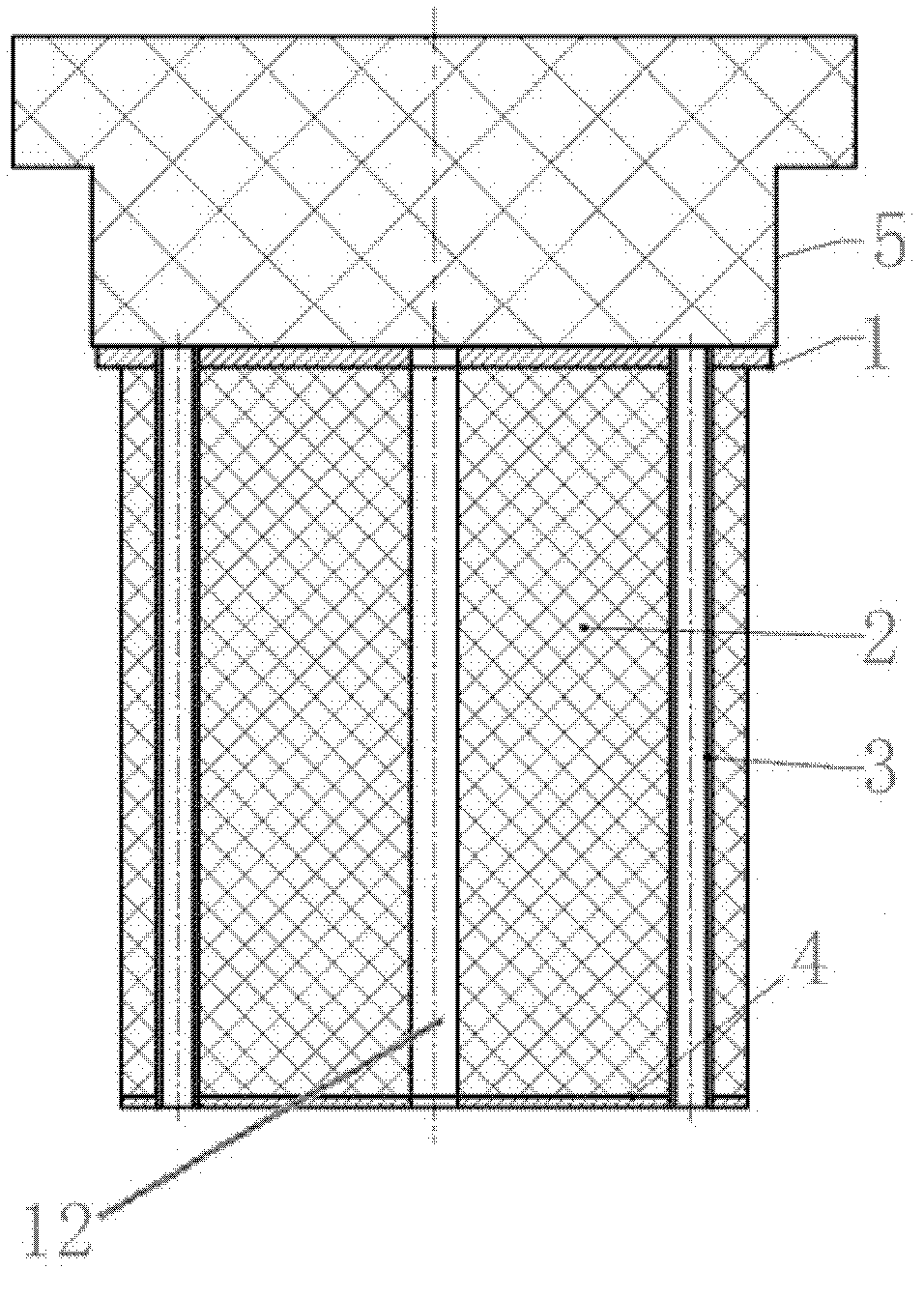

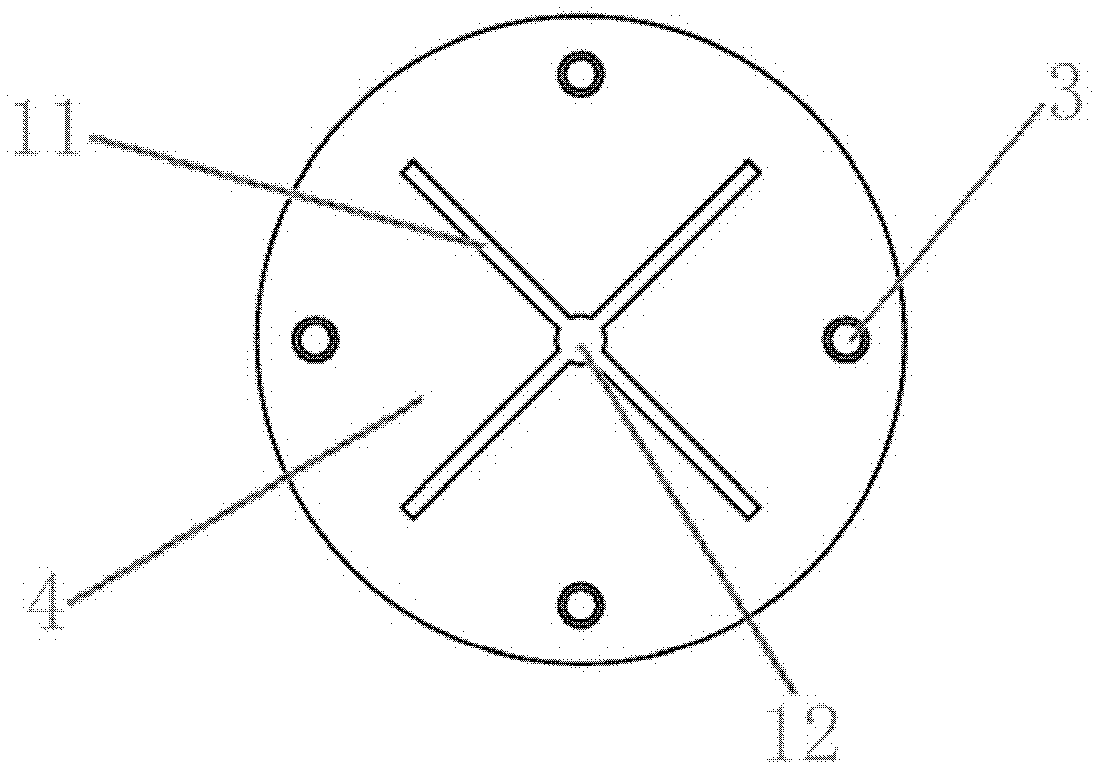

[0018] refer to figure 1 and figure 2 , the present embodiment includes a top plate 1, a refractory fiber 2, several steel pipes 3 and a bottom plate 4, the top plate 1 is fixedly connected to the bottom plate 4 through the steel pipe 3, the refractory fiber 2 is arranged between the top plate 1 and the bottom plate 4, and the top plate 1 An easy-to-detachable gland 5 is provided on the top plate; a cross groove 11 and a through hole 12 located in the center of the cross groove are arranged on the top plate 1, and the cross groove 11 and the through hole 12 run through the top plate 1 and the refractory fiber 2 from top to bottom And the bottom surface of the bottom plate 4.

[0019] In this embodiment: the compression amount of the refractory fiber 2 is 30%-40%. The number of the steel pipes 3 is four, and the steel pipes 3 are evenly distributed; both ends of the steel pipes 3 are welded to the top plate 1 and the bottom plate 4 respectively. The steel pipe is used not o...

specific Embodiment 2

[0023] The characteristics of this embodiment: the number of the steel pipes 3 is three, five, six, seven or eight. Others are the same as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com