Control method for inhibiting deflagration of high volatile coal

A control method and high volatile content technology, applied in the direction of program control, computer control, general control system, etc., can solve the problems that cannot be fully adapted to the blending of new coal types, increased fuel procurement costs, and great threats to production safety, etc., to reduce Fuel cost, solution to deflagration phenomenon, and convenient management

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

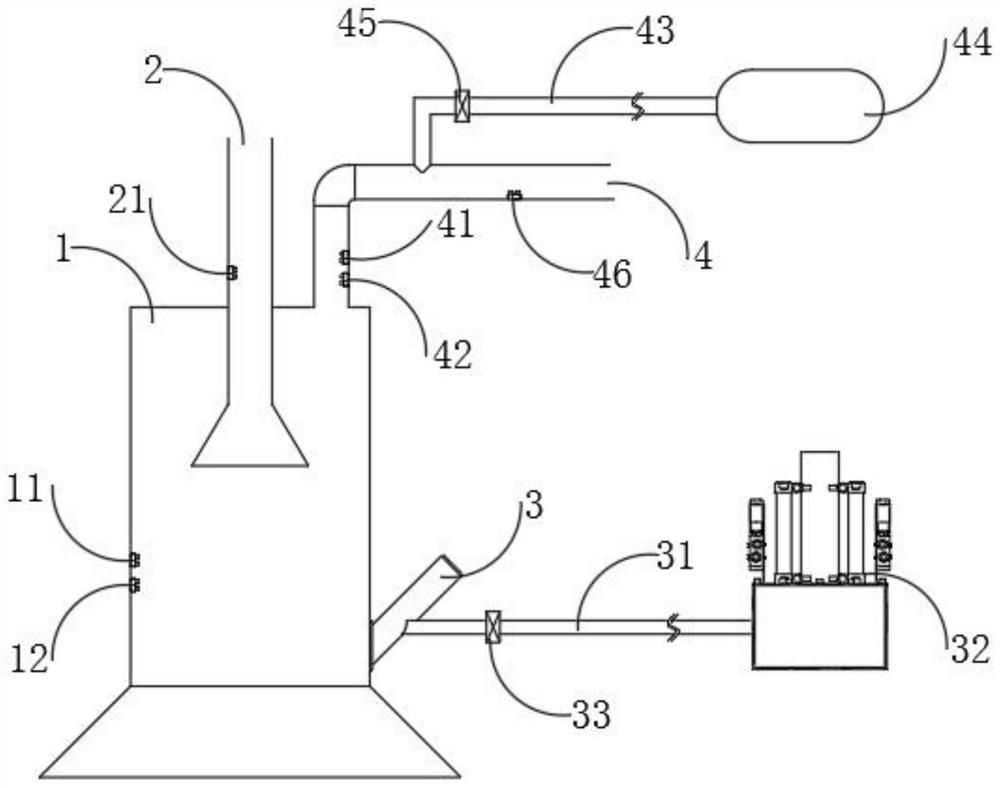

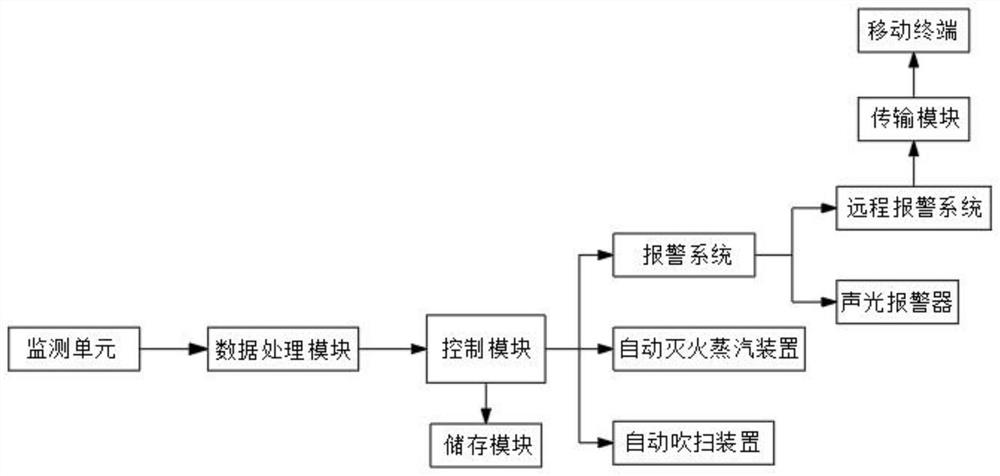

[0031] like Figure 1 to Figure 5 As shown, the present embodiment suppresses the control method of high volatile coal deflagration, and the control method includes the following measures:

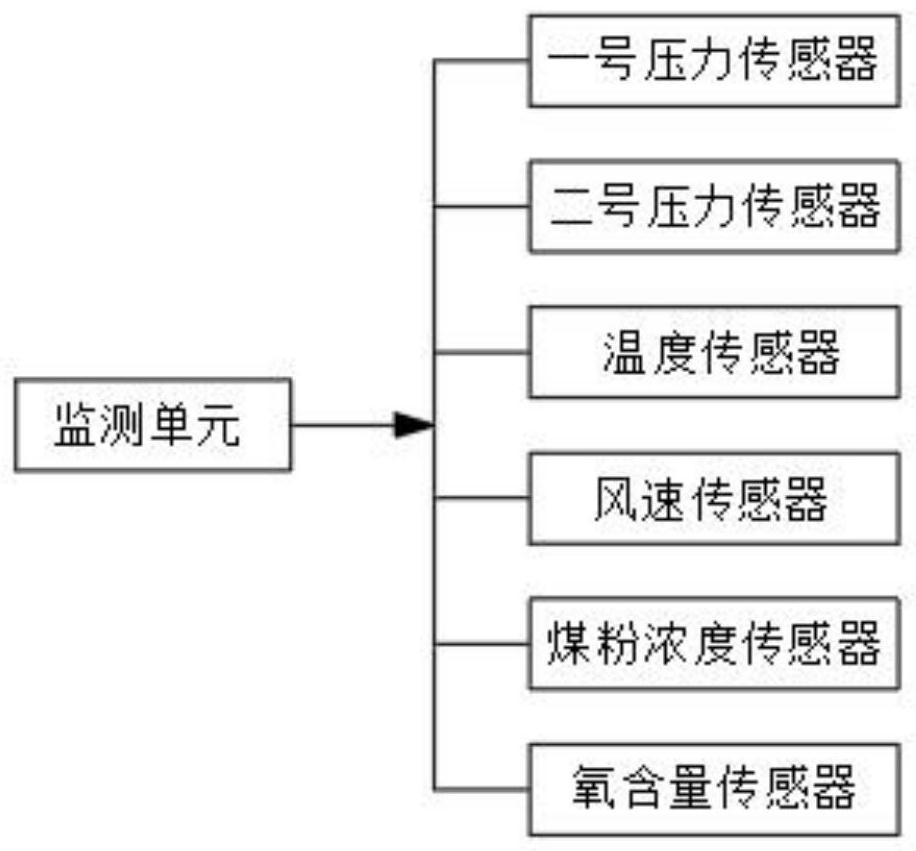

[0032] Measure 1. Judgment and automatic treatment of coal mill deflagration accidents: monitor the pressure at the inlet and outlet of the coal mill and the temperature at the outlet of the coal mill. The coal mill deflagration accident alarm system is triggered and the coal mill automatic fire extinguishing steam device is automatically started;

[0033] Measure 2. Automatic purge of coal mill and pulverized coal pipe: Monitor the wind speed of any coal pulverizer outlet pulverized pipe. Purge the pulverizer outlet powder pipe;

[0034] Measure 3. Wind speed monitoring of pulverized coal pipeline: add wind speed measuring points to the pulverized coal pipeline, and the position of the measuring point is 2.5 meters away from the shrinkable elbow of the pulverized coal pipeline;

[0035...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com