Method for manufacturing through hole pad on step structure of printed circuit board (PCB) and PCB

A technology of a ladder structure and a PCB board, which is applied to the formation of electrical connection of printed components, electrical connection of printed components, printed circuit components, etc., can solve the problems of complex manufacturing methods and high costs, and achieve simple manufacturing methods, low costs, and manufacturing methods. simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

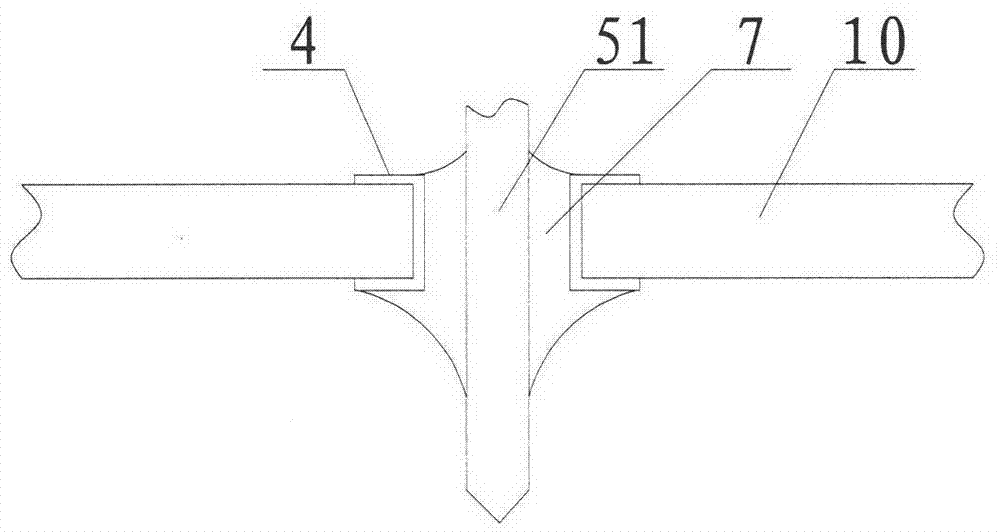

[0051] The method for manufacturing the through-hole pad at the step structure on the PCB provided by the embodiment of the present invention at least includes the following steps:

[0052] S1. Fabrication and lamination of each inner layer;

[0053] The steps of making and laminating the inner layers in this embodiment are the same as the steps of making and laminating the inner layers in the method for making a multi-layer PCB in the prior art, and will not be repeated here. When actually manufacturing the through-hole pads on the PCB, the laminated substrate can be used directly. Of course, if the substrate is a single-layer board, the steps of making and laminating each inner layer can also be omitted.

[0054] S2, making through holes:

[0055] in such as Figure 7 A through hole 2 is processed at a preset position on the substrate 1 shown, and the opening diameter of the through hole 2 on the bottom surface 12 of the substrate 1 (the diameter refers to the inner diame...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com