Rolling Force Presetting Method of Ultra Thin Plate Tempering Mill

A technology of temper rolling and rolling force, which is applied in the field of rolling force pre-setting of ultra-thin plate tempering machine, which can solve the problems of inaccuracy and achieve the effect of strong applicability and fast calculation speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

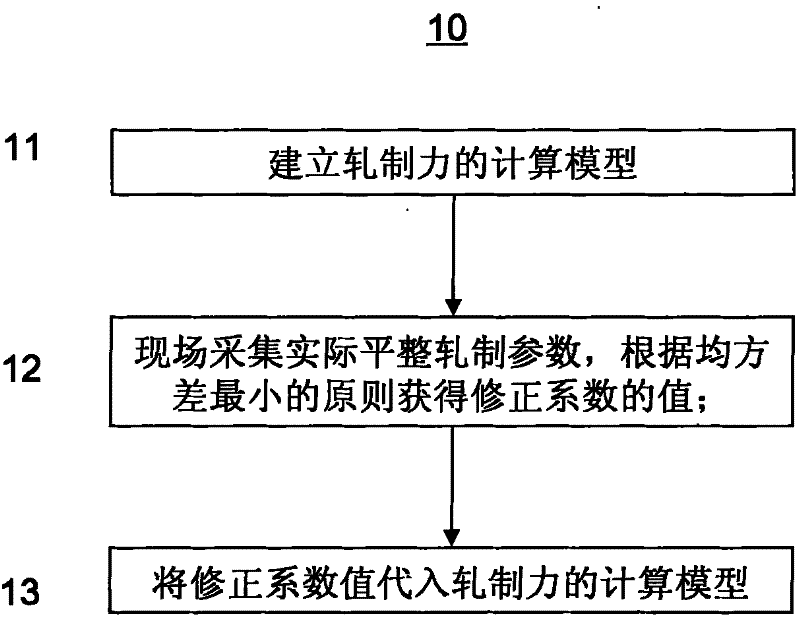

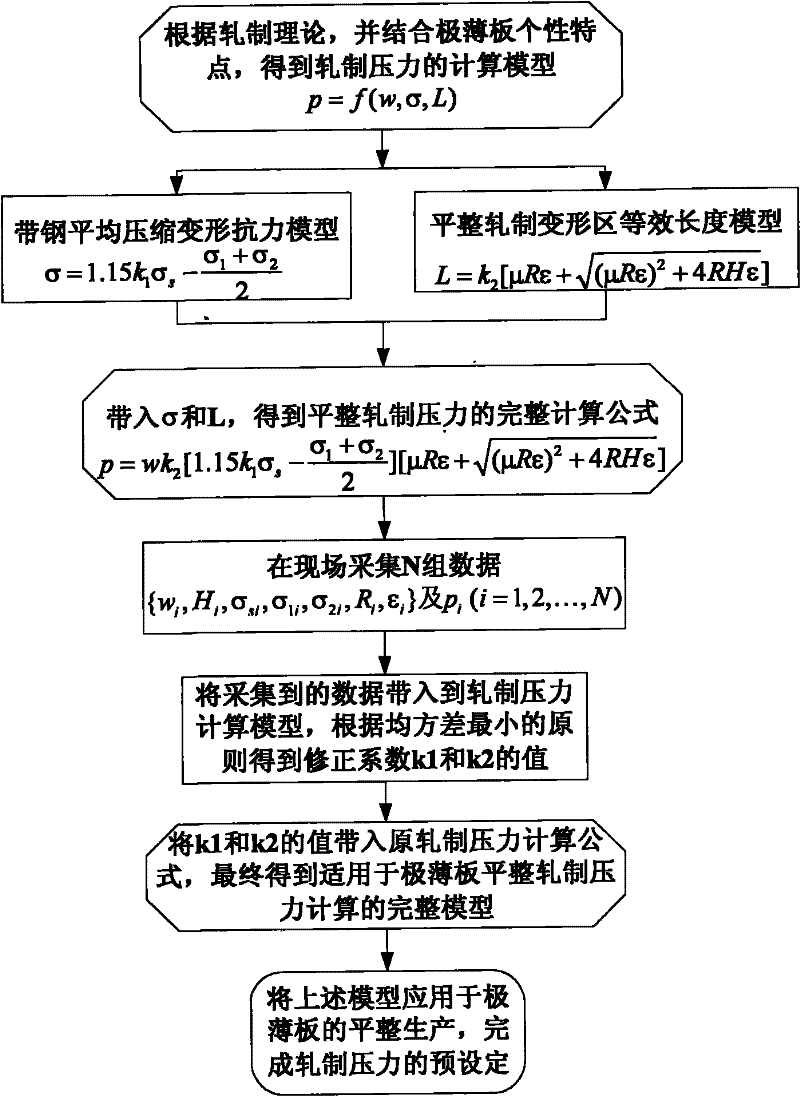

Method used

Image

Examples

Embodiment 1

[0071] Now refer to figure 2 The flow chart of pre-setting the temper rolling pressure is shown, taking the softest steel DC06 as an example to illustrate the process and effect of pre-setting the temper rolling pressure.

[0072] First, 100 groups (N=100) of temper rolling process parameters and corresponding actual temper rolling pressures of DC06 strip were collected on site.

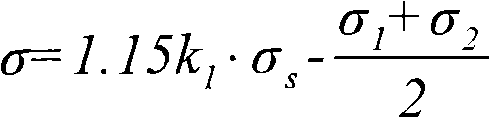

[0073] Then, determine the strip average compression deformation resistance correction coefficient k 1 Correction factor k for equivalent length of deformation zone in temper rolling 2 value. For DC06 strip steel, k 1 =3.55,k 2 =2.76.

[0074] Subsequently, the value of the coefficient of friction constant is determined. Here, μ=0.10 is taken.

[0075] Finally, according to the calculation formula (3), the calculated value of the temper rolling pressure is obtained. Comparing it with the actual value, the error between the two is less than 17%, which meets the requirements of engineering pra...

Embodiment 2

[0077] Taking the medium-strength steel BLCJD3 as an example, and combining with the method for presetting the temper rolling pressure introduced in the present invention, the realization process of the temper rolling pressure presetting will be further described.

[0078] First, 66 groups (N=66) of temper rolling process parameters and corresponding actual temper rolling pressures of BLCJD3 strip were collected on site.

[0079] Then, determine the strip average compression deformation resistance correction coefficient k 1 Correction factor k for equivalent length of deformation zone in temper rolling 2 value. For BLCJD3 strip steel, k 1 = 3.5,k 2 =4.73.

[0080] Subsequently, the value of the coefficient of friction constant is determined. Here, μ=0.10 is taken.

[0081] Finally, according to the calculation formula (3), the calculated value of the temper rolling pressure is obtained. Comparing it with the actual value, the error between the two is less than 12%, whic...

Embodiment 3

[0083] The following takes the high-strength steel B410LA as an example to illustrate the realization process of presetting the temper rolling pressure.

[0084] First, 50 groups (N=50) of temper rolling process parameters and corresponding actual temper rolling pressures of B410LA strip steel were collected on site.

[0085] Then, determine the strip average compression deformation resistance correction coefficient k 1 Correction factor k for equivalent length of deformation zone in temper rolling 2 value. For B410LA strip steel, k 1 = 1.6,k 2 =2.60.

[0086] Subsequently, the value of the coefficient of friction constant is determined. Here, μ=0.10 is taken.

[0087] Finally, according to the calculation formula (3), the calculated value of the temper rolling pressure is obtained. Comparing it with the actual value, the error between the two is less than 15%, which meets the requirements of engineering practice.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| friction coefficient | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com