Magnetic conductive bath specifically for electroplating of insertion-type light-emitting diode (LED) support

A technology of LED bracket and in-line technology, applied in the direction of plating tank, etc., can solve the problems of easy oxidation conductive contact, peeling, large consumption of copper sheet, etc., and achieve the effect of enhancing the conductive effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific illustrations.

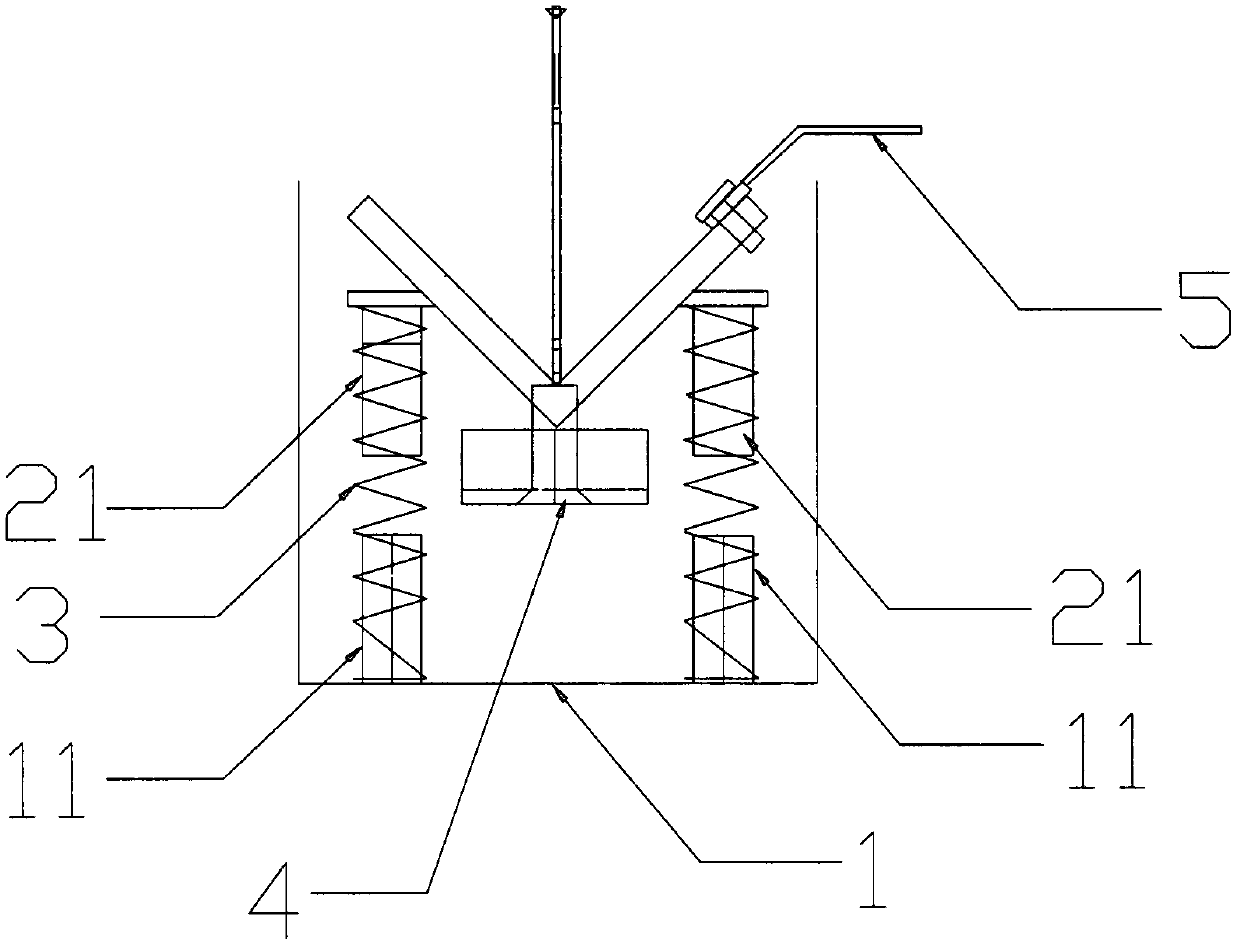

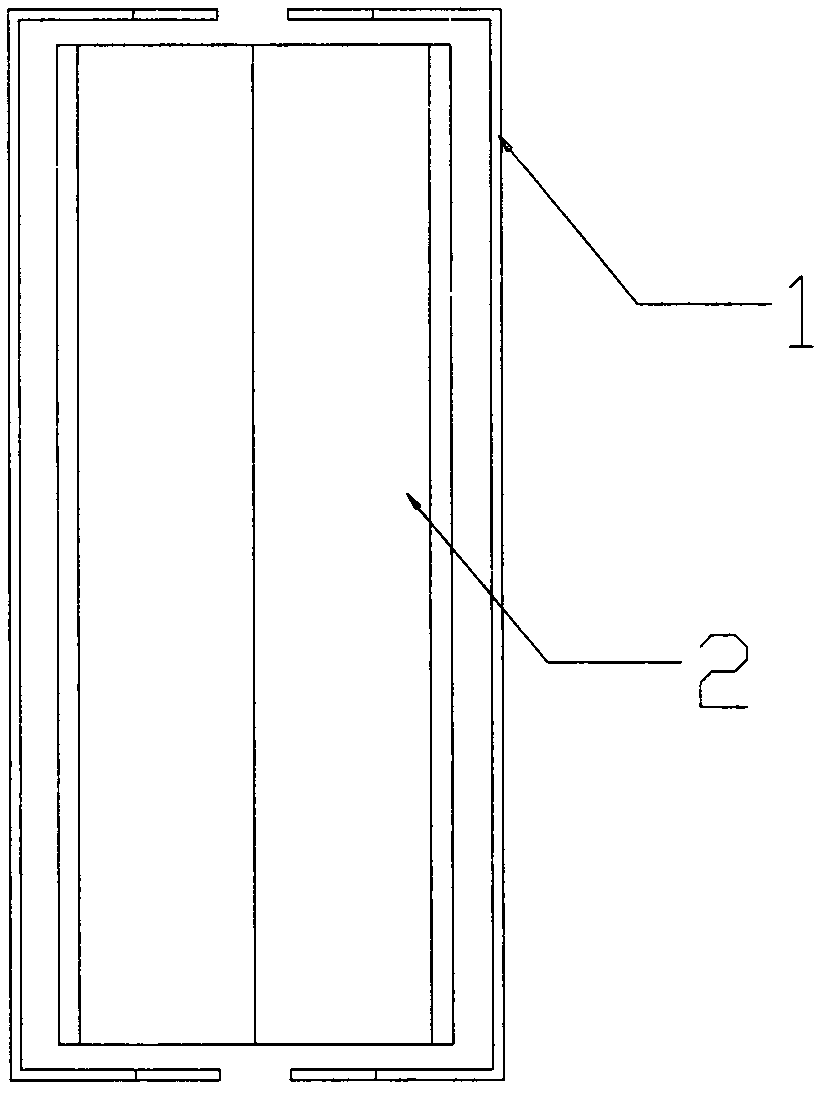

[0018] Such as figure 1 and figure 2 As shown, the electroplating special-purpose magnet conduction groove of in-line LED bracket of the present invention, it comprises rectangular stainless steel conduction seat 1, " V " shape groove 2, spring 3 and permanent magnet 4; The inner bottom of described rectangular stainless steel conduction seat 1 is provided with There are plural pairs (usually two or more pairs are provided according to actual needs) of lower fixing columns 11 symmetrically distributed. The lower fixing column 11 corresponds to the upper fixing column 21 arranged below the "V"-shaped groove 2, and the "V"-shaped groove 2 and the rectangular stainless steel conductive seat 1 are connected by the outer spring 3 between each pai...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com