Acoustic method for judging damage to film and optical element

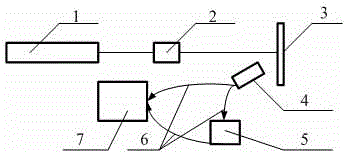

A technology of optical components and thin films, which is applied in processing the response signals of detection and analyzing solids by using sonic/ultrasonic/infrasonic waves, etc., can solve the problems of complex device, difficult to give, and inconsistent test results of different people, and achieves a simple structure. , relatively low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

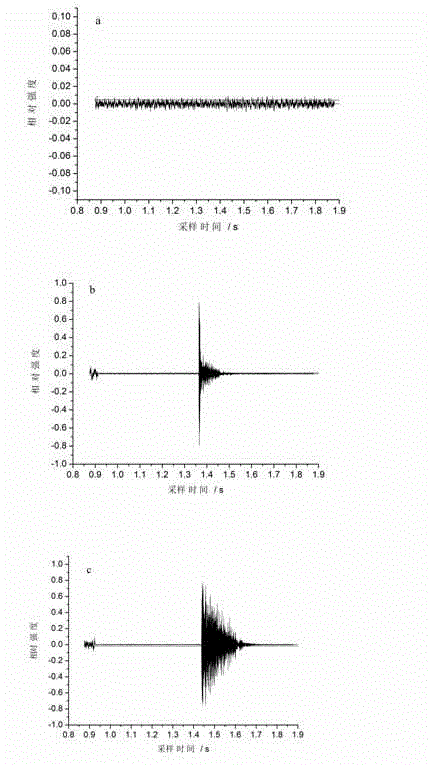

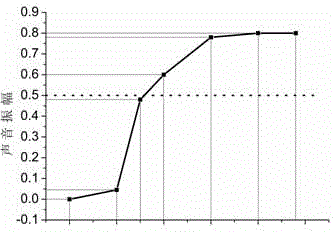

[0021] Embodiment 1: Utilize the method of the present invention to test the damage of film

[0022] figure 2 Given is the time-domain spectrum of the acoustic wave signal obtained when different laser pulse energies are collected when the film is damaged. Figure a is the time-domain curve of the acoustic signal obtained when the pulse damage energy is small, and the normalized amplitude intensity is 0.04; after increasing the laser pulse energy, the amplitude of the time-domain signal intensity increases to 0.6 as shown in Figure b; further With increasing energy, the time-domain signal strength amplitude increased to 0.8 (see panel c). The problem is how much the sound signal strength reaches, and it is considered that the membrane has been damaged, that is, the damage criterion is difficult to determine. The general practice is to measure the intensity of the acoustic signal under different damage pulse energies for a specific film, and make a curve of intensity peak an...

Embodiment 2

[0024] Embodiment 2: Utilize the method of the present invention to test the damage of optical element

[0025] Figure 5 The time-domain spectrum of the acoustic signal obtained when different laser pulse energies are collected when the optical element is damaged is given. Figure a is the time-domain curve of the acoustic signal obtained when the pulse damage energy is small, and the normalized amplitude intensity is very weak; after increasing the laser pulse energy, the amplitude of the time-domain signal intensity increases to 0.8 as shown in Figure b. There remains the question of how to identify damage. For this reason, we obtained frequency-domain spectrograms of time-domain signals under two different energies through the acoustic signal frequency-domain positioning system 5, as shown in Image 6 (a) and (b), in Image 6 In (b), there is obviously a sequentially enhanced spectral density around 4500 Hz, while Image 6 In (a), there is no obvious characteristic freq...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com