A flexible reinforced structure anti-drag rubber sheath flexible cable

A technology of strengthening structure and flexible cable, applied in the direction of insulated cable, bendable cable, cable, etc., can solve the problems of long-term normal use of the cable, discount of bending performance, affecting bending and winding performance, etc., to improve the bending performance. Towing performance, extended service life, reduced energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

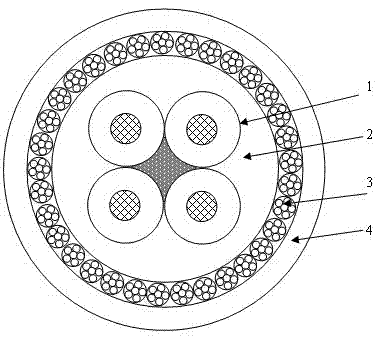

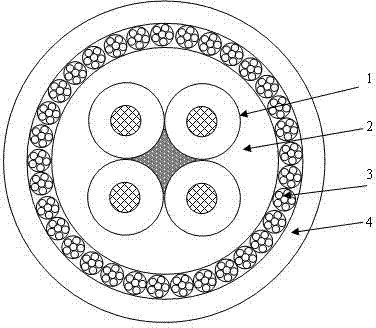

[0010] Such as figure 1 As shown, a flexible reinforced structure anti-drag rubber-sheathed flexible cable according to the present invention includes a cable core 1 located in the center of the cable. The cable core in this embodiment is formed by twisting four insulated wire cores. It can be combined by several insulated wire cores. The inner sheath 2 is extruded outside the cable core 1, and then the reinforcement rope 3 is evenly wound and stranded on the outer surface of the inner sheath to form a reinforcement layer, and then the outer sheath 4 is tightly extruded outside the reinforcement layer.

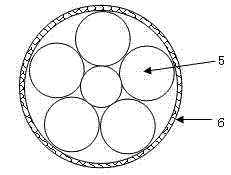

[0011] Such as figure 2 , the reinforcing rope 3 is an aramid yarn reinforcing rope, and its structure is to twist and twist several strands of aramid yarn 5 together, and then weave a layer of aramid yarn 6 on the outer surface of the twisted aramid yarn. The invention replaces the single sheath structure of the traditional cable, that is, after the rubber insulated wire c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com