Safety power supply device of set battery

A power supply device and battery technology, which is applied to battery pack components, secondary battery repair/maintenance, circuits, etc., can solve the maintenance and management loopholes of collective batteries, cannot stack multiple collective batteries, and cannot directly visually observe the single battery. Problems such as abnormal appearance of a secondary battery

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

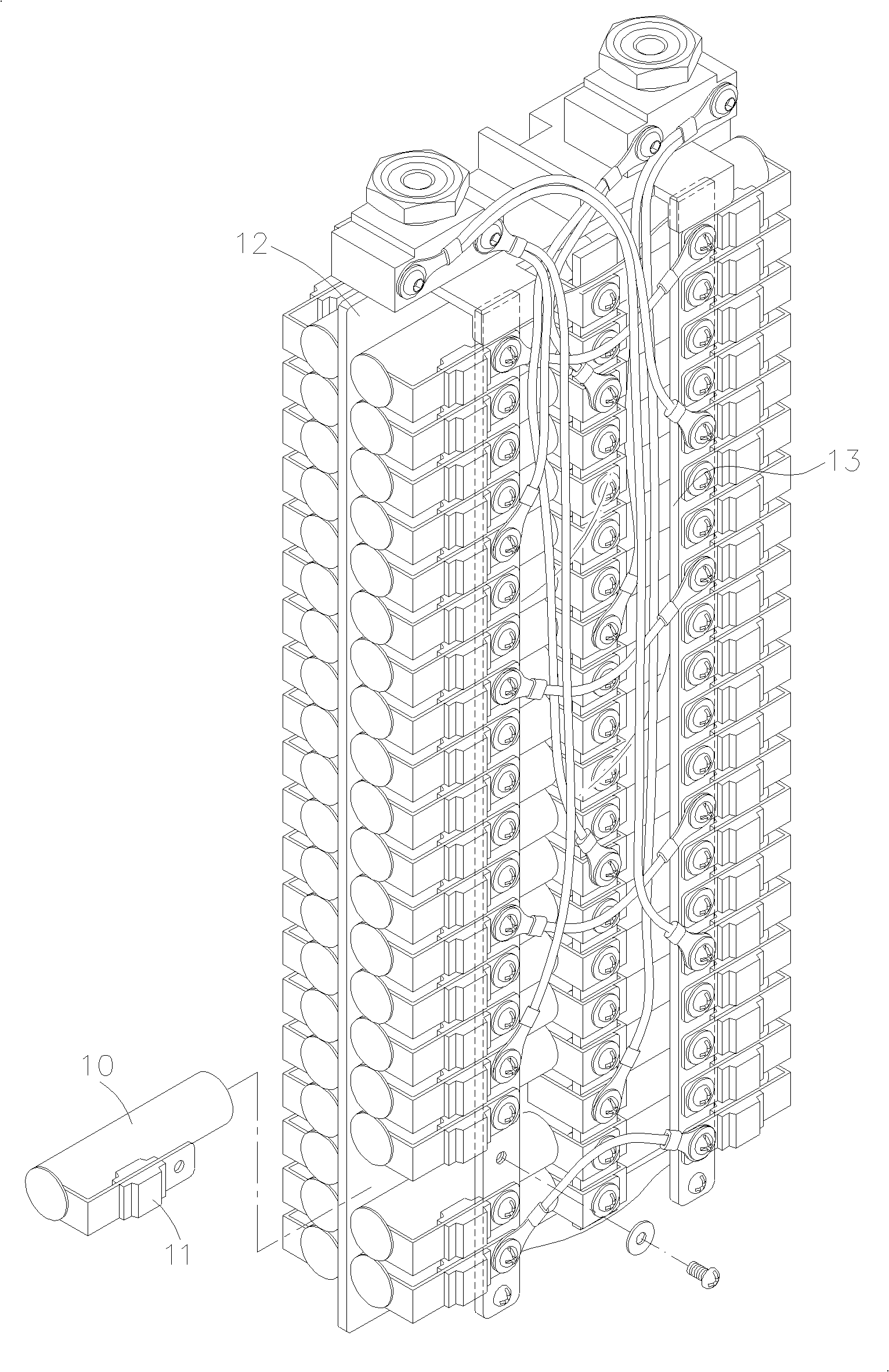

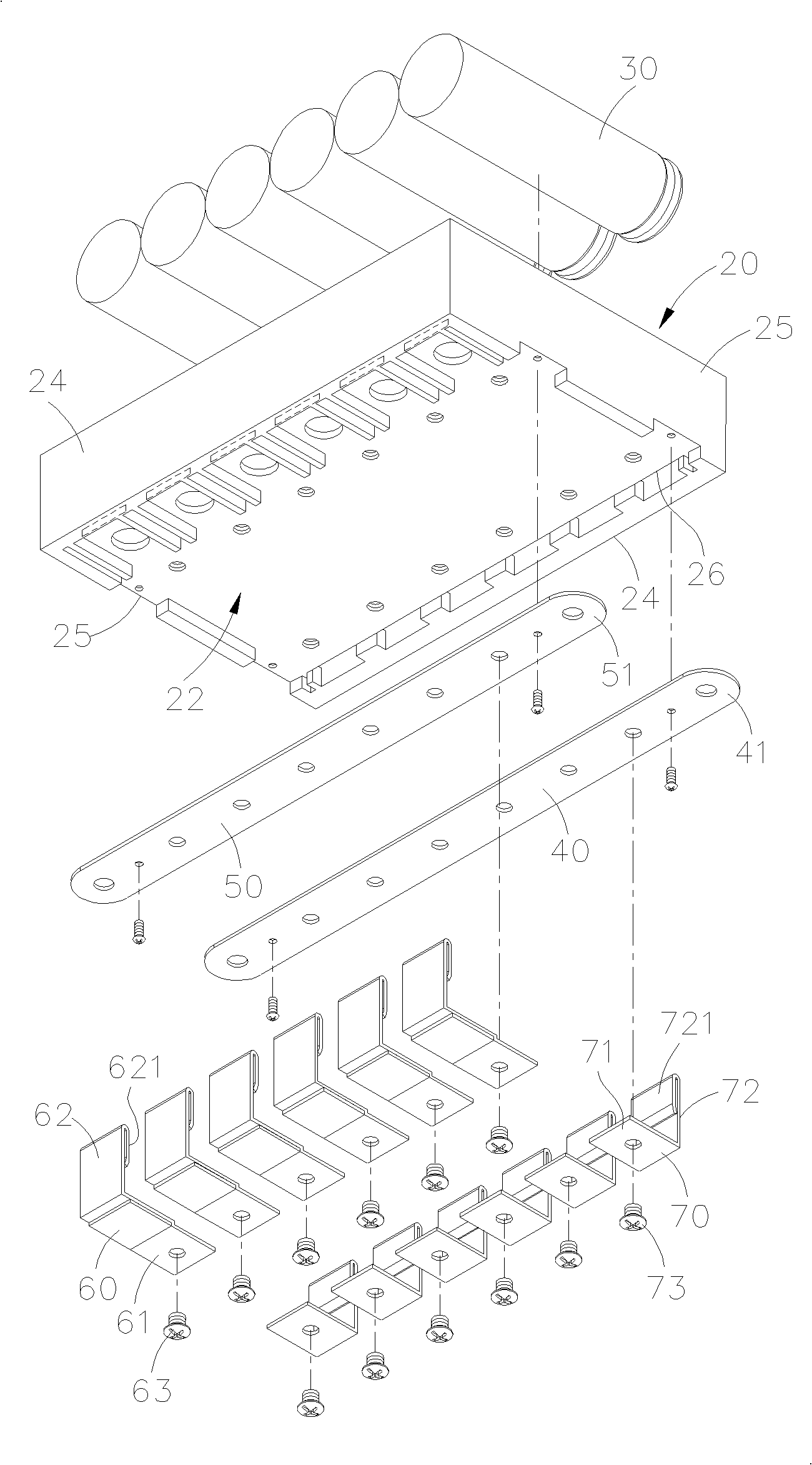

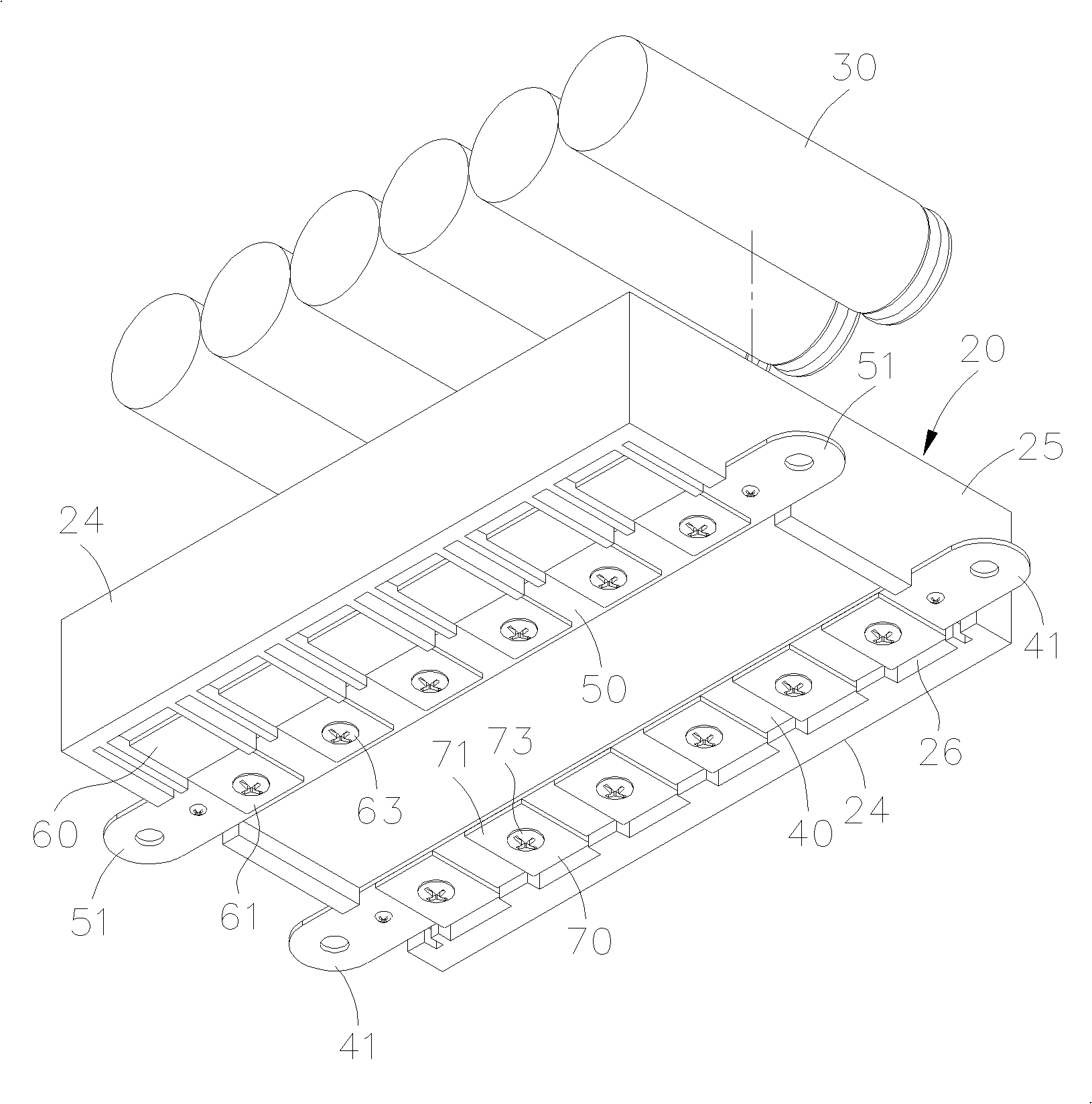

[0042] First, please refer to figure 2 , 3 As shown in and 4, a safety power supply device for an assembled battery provided by an embodiment of the present invention is mainly provided with a plurality of single secondary batteries on one side of a frame, and a positive electrode is installed on the other side of the frame Conductive strips, a negative conductive strip and multiple fuses, each single secondary battery is connected to the positive and negative conductive strips through multiple connectors and fuses, so that each single secondary battery is individually connected to a fuse , thus forming a collection battery.

[0043] Its specific structure is: the frame 20, the corresponding two sides are respectively formed into a housing groove 21 and a set of surface 22, the housing tank 21 is a quadrilateral structure with four side frames, and the housing tank 21 The back side of the bottom 23 is the aforementioned assembling surface 22, wherein, the two sides correspo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com