Carrier structure for drum brakes and method for assembling the carrier structure

A drum brake and carrier technology, applied in drum brakes, hydraulic drum brakes, mechanically driven drum brakes, etc., can solve the problems of inefficient assembly of drum brakes, limited accessibility and pre-assembly range, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] figure 1 A motor vehicle 1 according to one embodiment of the invention is shown schematically. The vehicle exemplified here is a heavy vehicle in the form of a truck. The vehicle has a powered rear axle X connected to the traction rear wheels and equipped with a configuration for rear axle drum brakes in the form of a carrier structure. In alternative embodiments, the invention may also be used on non-traction, non-steering wheels.

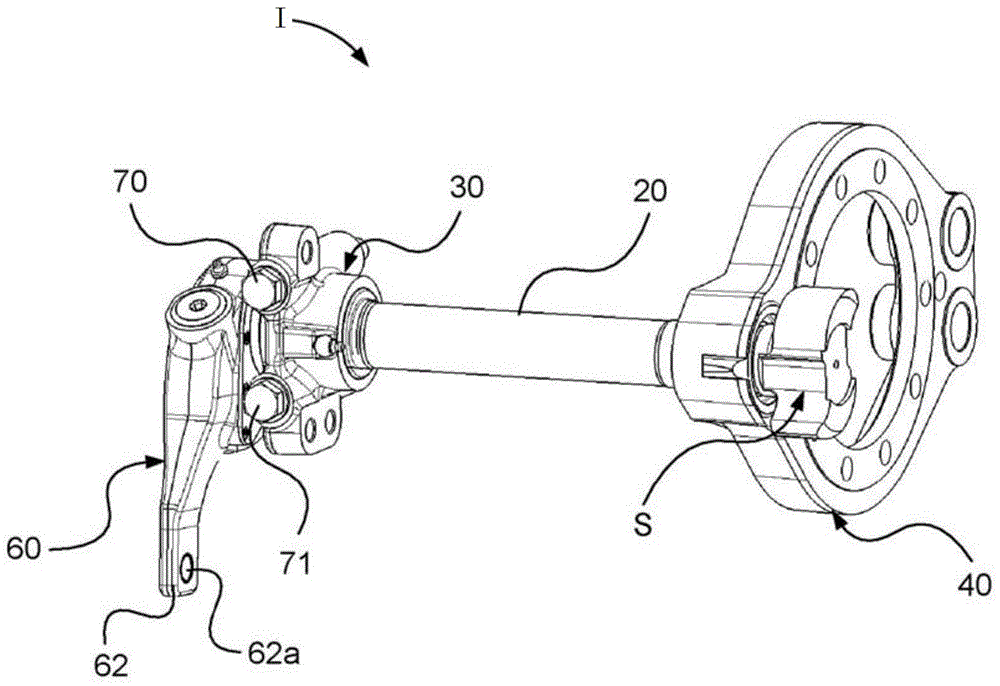

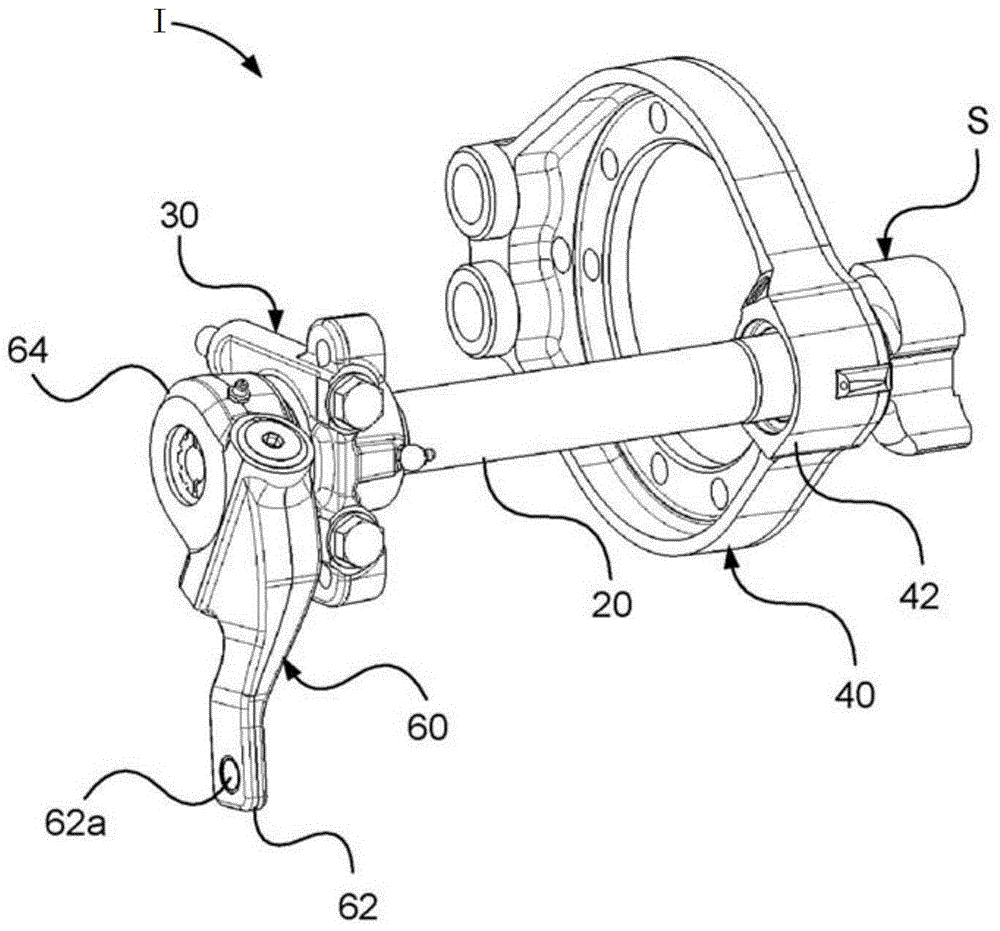

[0022] Figure 2a-2b are different schematic perspective views of a part of a rear axle X with a part of a drum brake comprising a carrier structure for a drum brake of a motor vehicle according to the invention; and Figure 3a -b is Figure 2a - Different schematic side views of the carrier structure in b with the brake cylinder 10 and the eccentric shaft 20 .

[0023] The carrier structure is configured to fasten the eccentric shaft 20 of the drum brake and fasten the brake cylinder 10 of the drum brake in a journal-fitting manner. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com