Welding wire cleaning device

A technology of cleaning device and welding wire, which is applied in the direction of metal extrusion cleaning equipment, metal processing equipment, manufacturing tools, etc., can solve the problems of black surface color of welding wire, affecting welding quality, normal use of welding equipment, and inability to clean welding wire, etc. good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

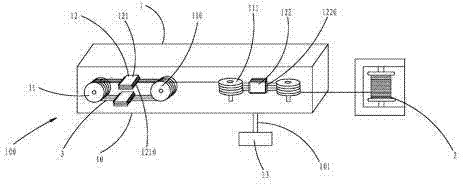

[0009] see figure 1 , a welding wire cleaning device 100, the welding wire cleaning device 100 includes: a cleaning unit 1 and a wire take-up machine 2, the cleaning unit 1 includes a machine base 10, a wire passing wheel 11 and a clamp 12 installed on the machine base 10, The wire passing wheels 11 include a pair of vertical wire passing wheels 110 and a pair of horizontal wire passing wheels 111, the axis of the vertical wire passing wheels 110 is parallel to the horizontal plane, and the axis of the horizontal wire passing wheels 111 Perpendicular to the horizontal plane, the clamp 12 includes a first clamp 121 and a second clamp 122, at least one first clamp 121 is arranged between the pair of vertical wire passing wheels 110, and the pair of horizontal wire passing wheels At least one second clamp 122 is provided between 111. In this embodiment, two first clamps 121 are provided between the pair of vertical wire passing wheels 110, and one of the pair of horizontal wire p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com