Grinding needle head loading and unloading machine

A technology for loading and unloading machines and needles, which is applied in the field of needle grinding, can solve the problems of low loading and unloading efficiency, low degree of automation, etc., and achieves good economic value and promotion value, and the effect of high-efficiency loading and unloading of needles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

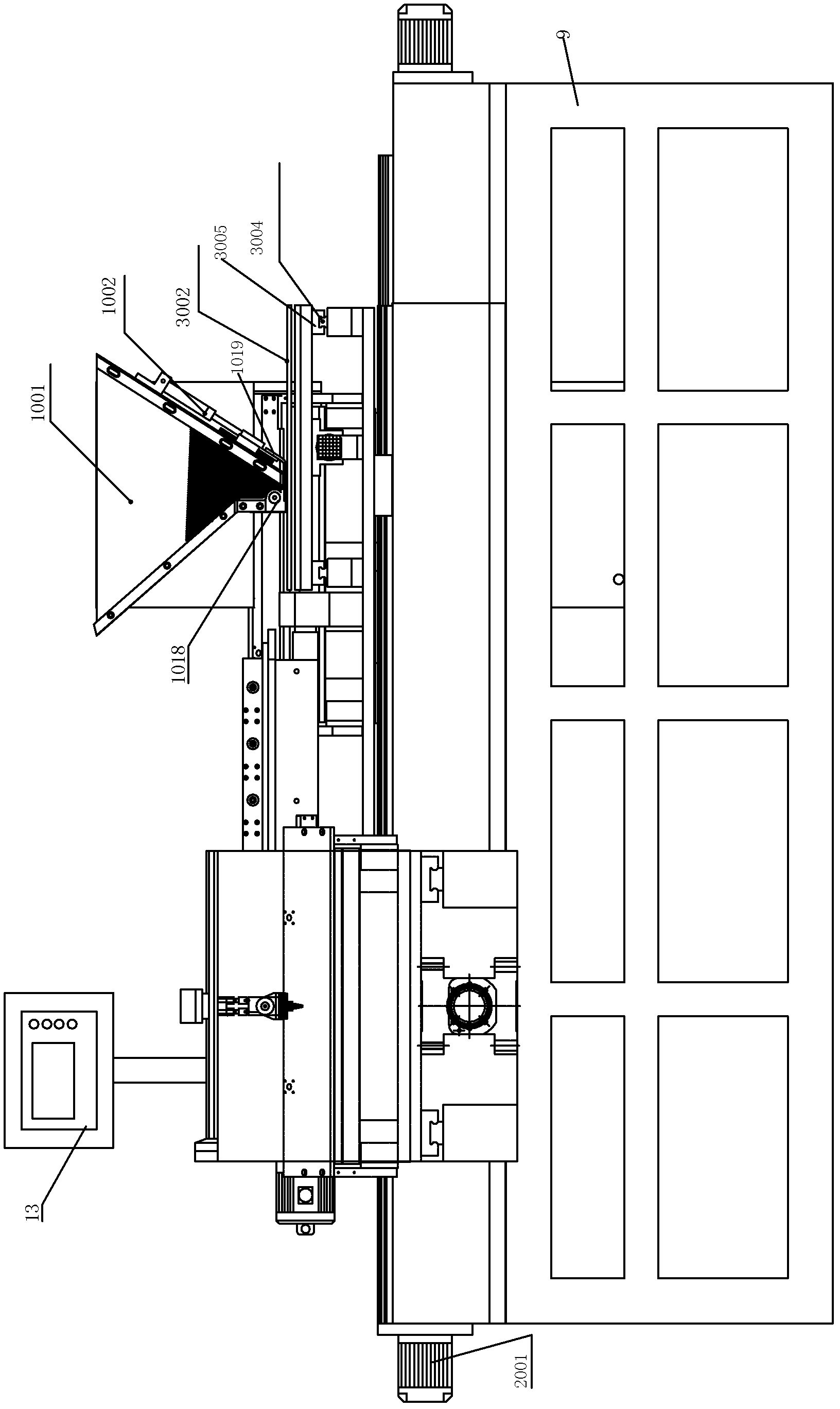

[0042] Next, a grinding needle loading and unloading machine of the present invention will be described in detail with reference to the accompanying drawings.

[0043] A grinding needle loading and unloading machine, the structure of which includes a frame 9; a mobile platform mechanism fixed on the frame 9 and a needle swing mechanism fixed on the frame 9 for placing needles; Neat flattening mechanism and needle clamping mechanism for clamping the neatly placed needles; both the bulldozing mechanism and the needle clamping mechanism are set on the mobile platform mechanism; the frame 9 is also provided with a main control The main controller 13 is electrically connected to and controls the moving platform mechanism, the needle swing mechanism, the flattening mechanism, and the needle clamping mechanism respectively. The needle swing mechanism mainly includes needle setting bucket 1001, needle setting cylinder 1002, swing needle servo motor 1003, swing needle screw rod 1005, s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com