Solvent-free esterification-distillation integrated process

The technology of esterification reaction and esterification reaction kettle is applied in the field of solvent-free esterification reaction-distillation integration process, which can solve the problems of increased production cost, poor compatibility, and higher requirements for esterification raw materials.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

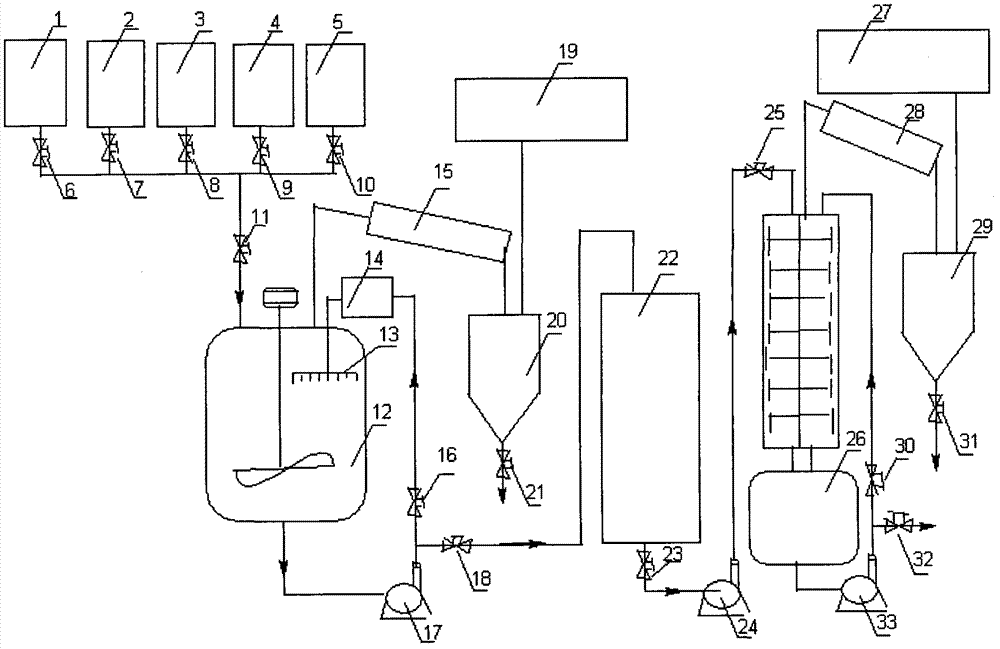

Image

Examples

Embodiment 1

[0021] Embodiment 1 (the synthesis of trimethylolpropane triheptanoate):

[0022] a. Add 134 kg of raw material trimethylolpropane and 2 kg of catalyst p-toluenesulfonic acid into the high-level feeding tank 1, add 400 kg of heptanoic acid into the high-level feeding tank 2, fill the high-level feeding tank 1 with nitrogen protection and start the heating system, so that the three Melt methylolpropane and p-toluenesulfonic acid, after the raw materials are fully melted, open the vacuum system 19, the vacuum pressure is 1000pa, close the valves 18 and 21 at the same time, open the valves 6, 7, 11 and 16, and the high-level feeding tanks 1 and 2 The raw materials inside are sucked into the esterification reactor 12 under the condition of negative pressure, and after the raw materials are completely sucked, the valve 11 is closed;

[0023] b. Turn on the vacuum system 19, turn on the condenser 15 and the high-temperature-resistant circulation pump 17 at the same time, and the mat...

Embodiment 2

[0025] Embodiment 2 (the synthesis of trimethylolpropane triheptanoate):

[0026] a. Add 134kg of raw material trimethylolpropane to the high-level feeding tank 1, add 400kg of heptanoic acid to the high-level feeding tank 2, fill the high-level feeding tank 1 with nitrogen protection and start the heating system to melt the trimethylolpropane. After the raw materials are fully melted, open the vacuum system 19, the vacuum pressure is 2000pa, close the valves 18 and 21 at the same time, open the valves 6, 7, 11 and 16, the raw materials in the high-level feeding tanks 1 and 2 are sucked into the In the esterification reaction kettle 12, after the raw materials are completely inhaled, close the valve 11;

[0027] b, open the vacuum system 19, open the condenser 15 and the high temperature resistant circulating pump 17 at the same time, the material is pumped out from the esterification reactor 12 through the high temperature resistant circulating pump 17, pass through the catalys...

Embodiment 3

[0029] Embodiment 3 (the synthesis of dumbbell-shaped product 2-trimethylolpropane-adipate-4-heptanoate):

[0030] a. Add 134kg of raw material trimethylolpropane to the high-level feeding tank 1, add 73kg of adipic acid to the high-level tank feeding 2, put 280kg of heptanoic acid into the high-level tank 3, fill the high-level feeding tanks 1 and 2 with nitrogen protection and start the heating system , to dissolve trimethylolpropane and p-toluenesulfonic acid. After the raw materials are fully dissolved, open the vacuum system 19, the vacuum pressure is 3000pa, close the valves 18 and 21 at the same time, open the valves 6, 7, 11 and 16, and the high-level feeding tank The raw materials in 1 and 2 are sucked into the esterification reactor 12 under the condition of negative pressure, and after the raw materials are completely sucked, the valve 11 is closed;

[0031] b, open the vacuum system 19, open the condenser 15 and the high temperature resistant circulating pump 17 at...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pour point | aaaaa | aaaaa |

| flash point | aaaaa | aaaaa |

| pour point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com