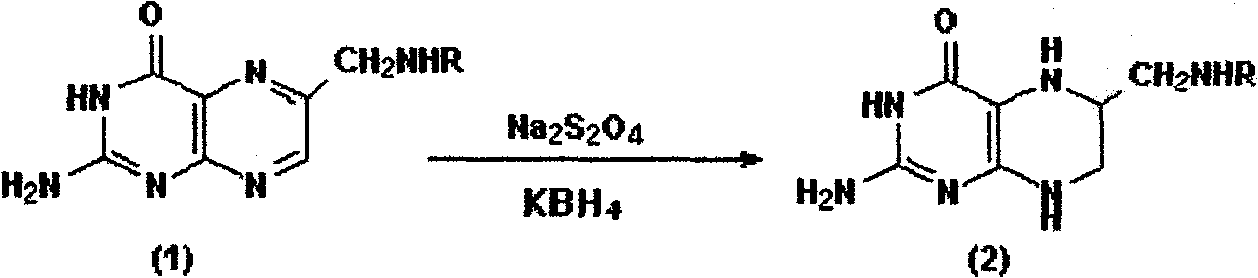

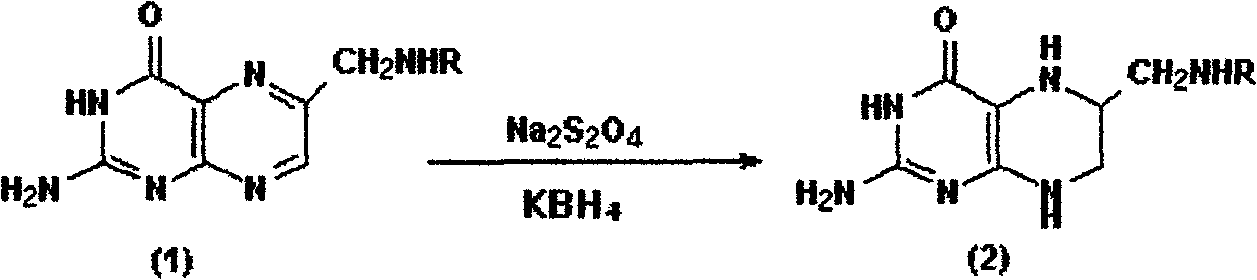

Preparation method of tetrahydrofolic acid

A technology of tetrahydrofolate and dihydrofolate, applied in the direction of organic chemistry and the like, can solve the problems of incomplete reduction reaction, large loss, low yield, difficult separation, etc., and achieves no by-product generation, low raw material consumption, and short process route. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0016] A preparation method of tetrahydrofolate, the steps are as follows:

[0017] 1. Dissolve 10g of sodium dithionite (sodium dithionite) in 150ml of pure water, and use a 250ml Erlenmeyer flask as the reaction vessel;

[0018] 2. Put 10g of folic acid into 1, add 2.4g of sodium hydroxide to dissolve the folic acid, at this time the pH is 9.0, and the solution is brownish red;

[0019] 3. Seal the mouth of the bottle with plastic wrap, pierce 2 pinholes to exhaust air, and synthesize for 3 hours; control the synthesis temperature at 15-20°C;

[0020] 4. Put 7g of potassium borohydride into 3, seal the mouth of the bottle with plastic wrap, pierce 2 pinholes to exhaust air, and synthesize at 15-20°C for 3 hours; the synthetic liquid is light brown, pH 10.50;

[0021] 5. Use 3M hydrochloric acid to adjust the pH of the synthetic solution to 3.5; filter under nitrogen to obtain off-white crystals, and the mother liquor is colorless;

[0022] 6. The wet product was washed thr...

Embodiment 2

[0024] A preparation method of tetrahydrofolate, the steps are as follows:

[0025] 1. Add 1200ml of pure water to a 3000ml beaker, add 24g of sodium hydroxide and 96g of dithionous acid under stirring, and stir to dissolve them completely;

[0026] 2. Weigh 120g of folic acid, add it to 1, stir to dissolve it completely, transfer it to a 3L glass synthesis kettle, start the synthesis kettle to stir, the rotation speed is 150rmp, the temperature is 25°C; the synthesis is 4 hours, and the pH is 5.50 at this time;

[0027] 3. Weigh 60g of potassium borohydride, add it to 2 in batches, and react at 20-25°C for 120 minutes, the synthetic liquid is light brown, pH 7.5;

[0028] 4. Mix the liquid with 3M hydrochloric acid at pH 3.0, filter it under the protection of nitrogen to obtain off-white crystals, and the mother liquor is colorless;

[0029] 5. Stir and wash the crystals with 1500ml of deionized oxygen-free ice water for 3 times, and filter under nitrogen protection to obtai...

Embodiment 3

[0032] A preparation method of tetrahydrofolate, the steps are as follows:

[0033] 1. Add 300L of pure water to a 500L stainless steel synthesis kettle, add 6kg of sodium hydroxide and 24kg of dithionous acid under stirring, and stir to dissolve them completely;

[0034] 2. Add 30kg of folic acid into the kettle, stir to completely dissolve, control the reaction temperature at 25-30°C, synthesize for 5 hours, and the pH at this time is 5.5;

[0035] 3. Add 18kg of potassium borohydride to 2 in batches, and react at 25-30°C for 2 hours, the synthetic liquid is light brown, pH 8.5;

[0036] 4. Mix the liquid with 3M hydrochloric acid at pH 3.0, filter it under the protection of nitrogen to obtain off-white crystals, and the mother liquor is colorless;

[0037] 5. Stir and wash the wet product with 300L deionized oxygen-free ice water to wash the crystals, and filter under the protection of nitrogen to obtain off-white crystals;

[0038] 6. Place the wet product in a vacuum fr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com