Preheating device of round bar mold insert used for cast

A preheating device and insert technology, applied in the field of casting, can solve problems such as unfavorable production continuity and affecting the consistency of round bar preheating temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

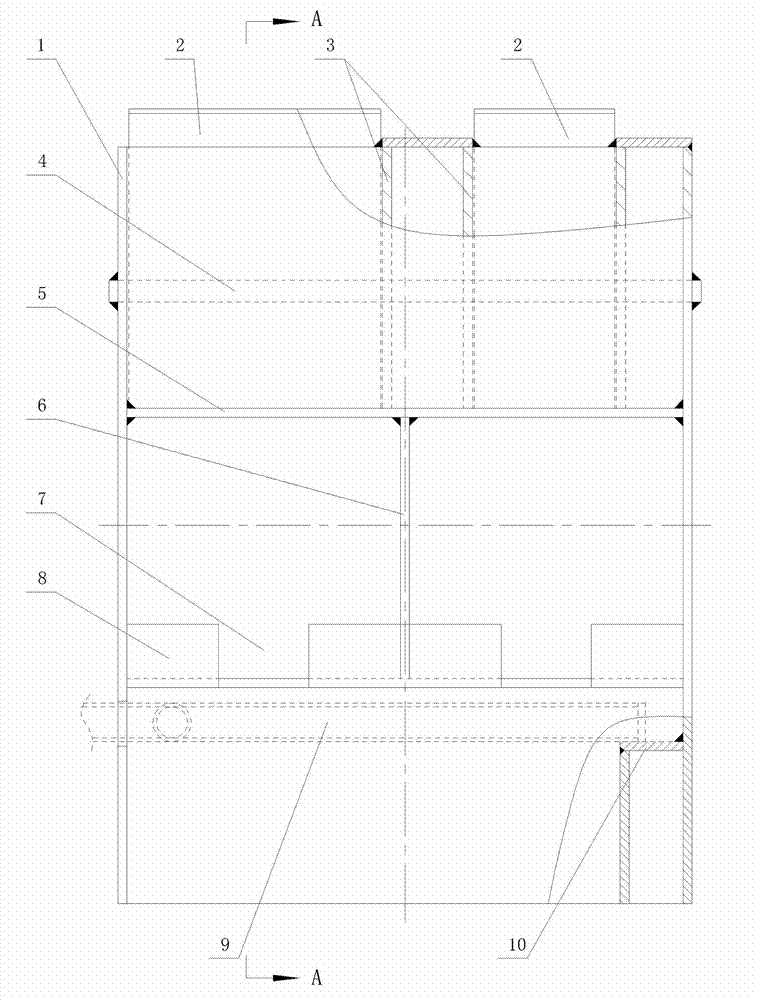

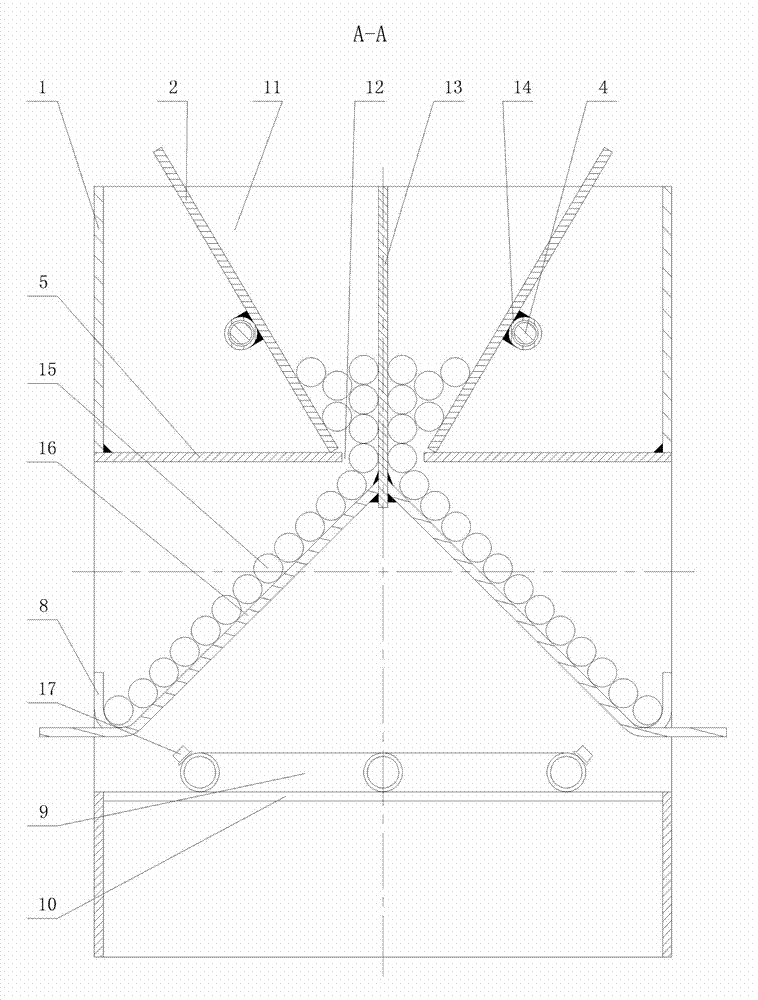

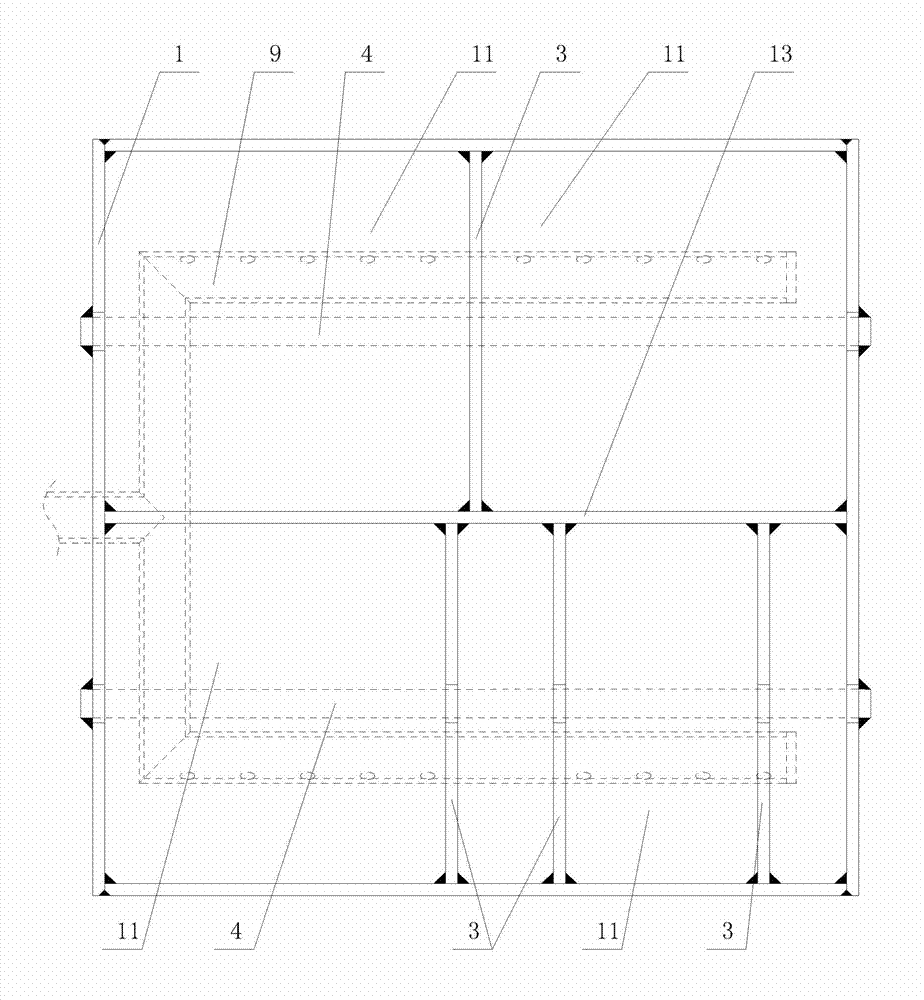

[0024] Depend on Figure 1 to Figure 5 As can be seen from the structural schematic diagram of the preheating device of the round bar insert for casting of the present invention, it includes a heating mechanism and a bracket with upper, middle and lower layers, the heating mechanism is located at the lower layer of the bracket, and the upper layer of the bracket is The discharge chamber 11, the middle layer of the support has an inclined blanking plate 16, the upper end of the blanking plate 16 is connected with the blanking opening 12 at the lower end of the discharging chamber 11, and the transverse dimension of the blanking opening 12 is larger than a circle The diameter of the rod insert 15 is less than the sum of the diameters of the two round rod inserts 15, and the lower end of the blanking plate 16 is a material intake.

[00...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com