Remote monitoring system for hollow axle flaw detector

A remote monitoring system and remote monitoring technology, applied in transmission systems, electrical components, etc., can solve problems such as the stability and security threats of hollow axle flaw detectors, and achieve the effect of ensuring security

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described in detail below in conjunction with the accompanying drawings, so that those skilled in the art can implement it with reference to the description.

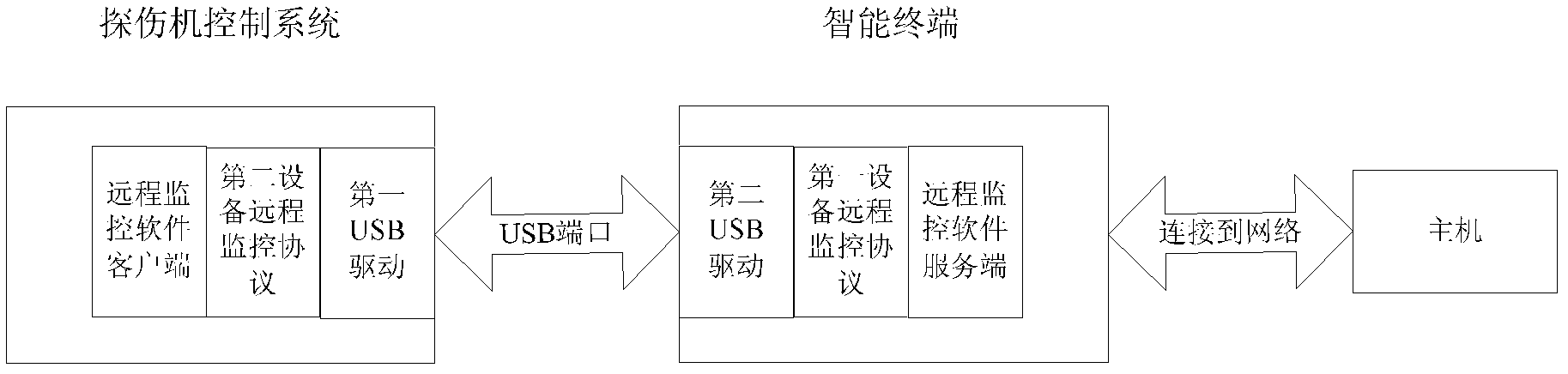

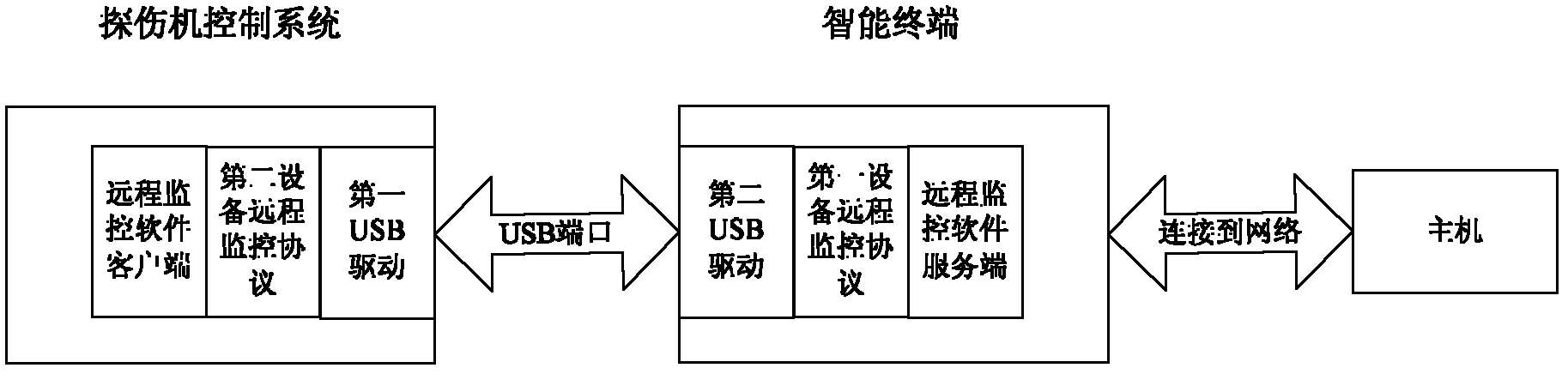

[0019] like figure 1 As shown, the present invention provides a remote monitoring system for a hollow axle flaw detector, including: remote monitoring software, which includes a client and a server, the client is set in the flaw detector control system, and the flaw detector is controlled After the system is turned on, the client is turned on, wherein the client is connected to the server through a port; the smart terminal is provided with the first remote monitoring protocol module and the server, and the smart terminal is turned on Afterwards, the server is opened, and the port between the client and the server is opened at the same time. After the port between the client and the server is opened, the server is connected to the server. The port between the client and the c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com