Air suspension system applied to heavy truck

An air suspension, heavy-duty truck technology, applied in the direction of suspension, elastic suspension, vehicle components, etc., can solve the problems of reduced ride comfort, increased fuel consumption, damage to on-board cargo, etc., to improve comfort and ride comfort, Reliable working condition and the effect of reducing the weight of the vehicle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

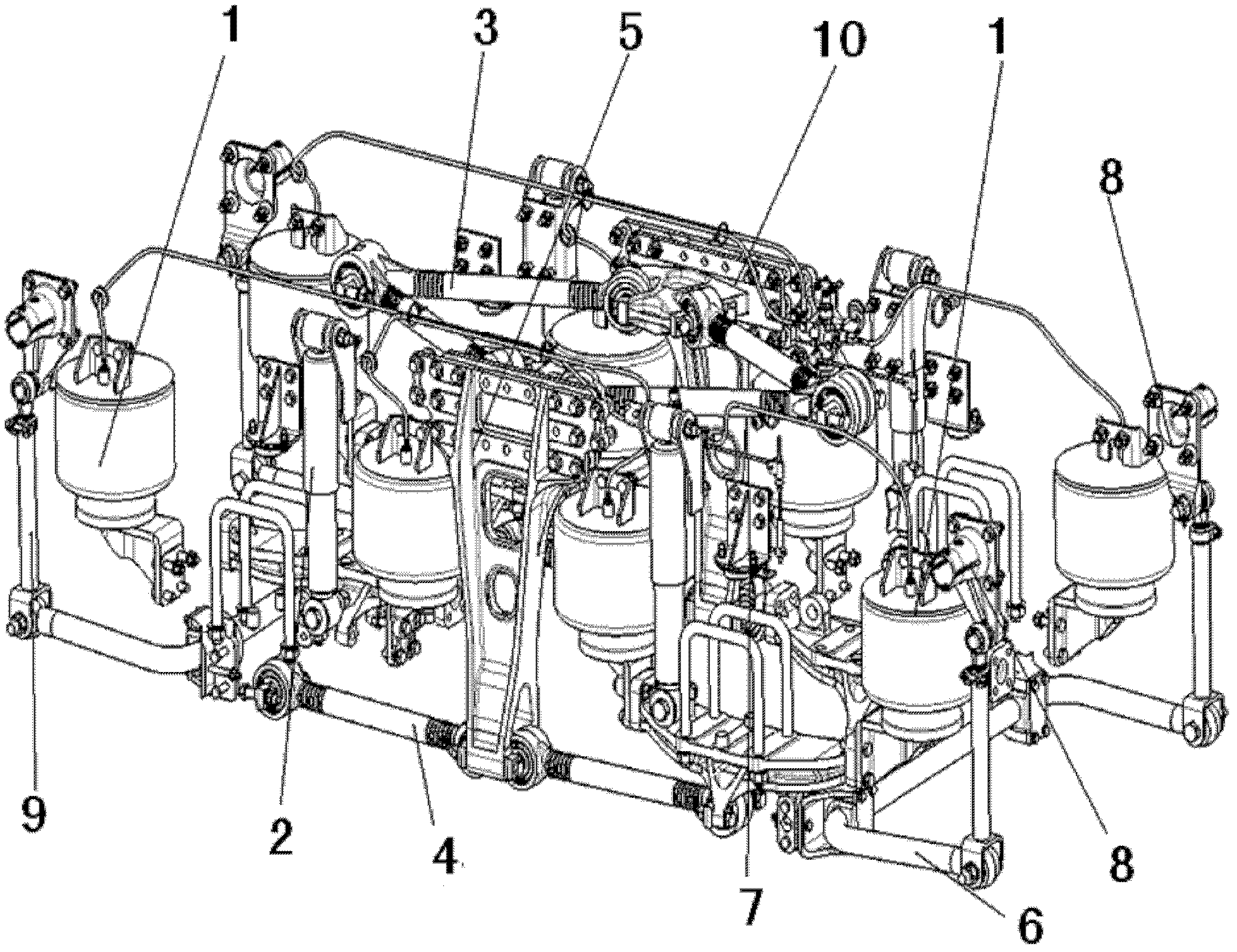

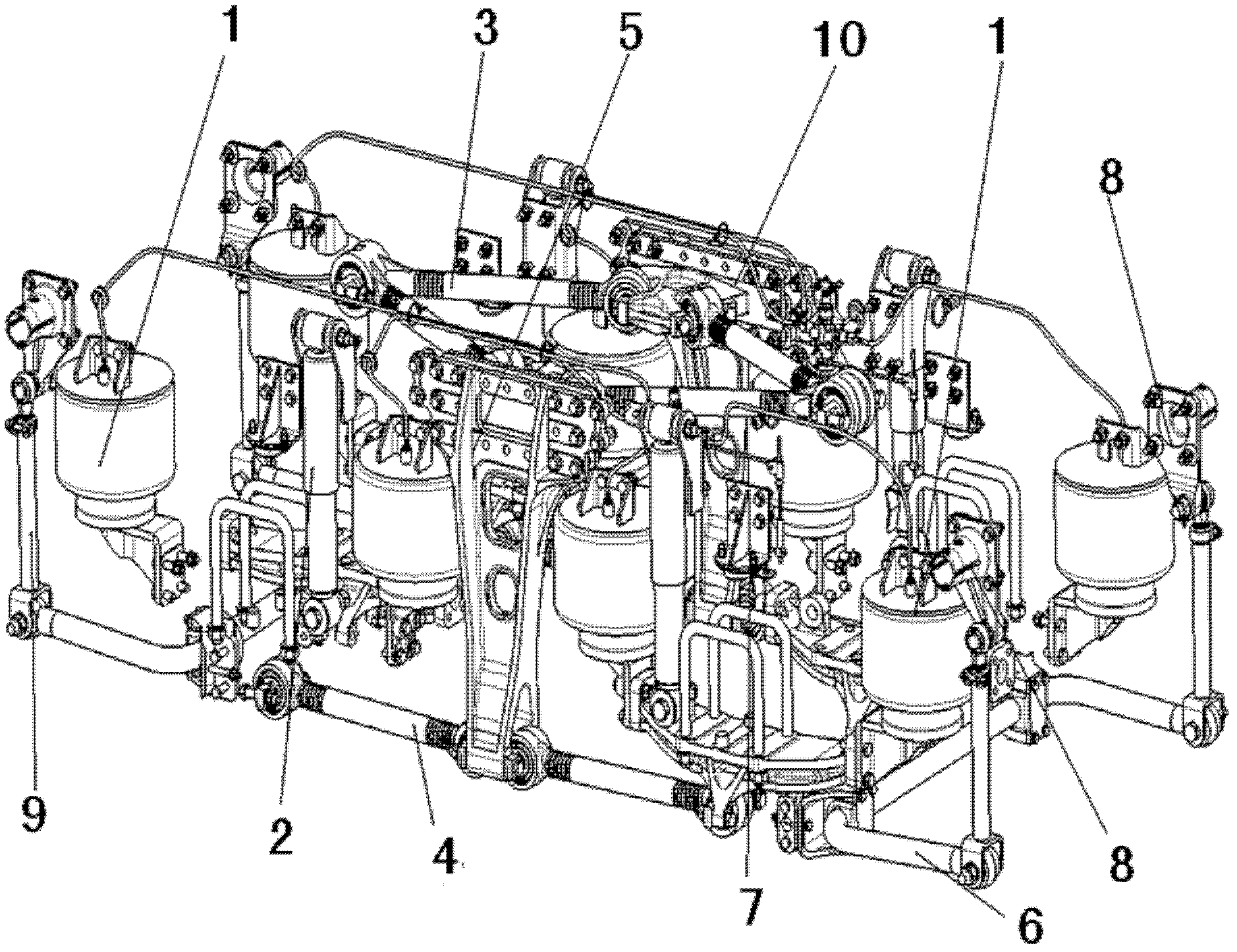

[0022] Such as figure 1 As shown, the technical solution provided by the present invention is an air suspension system applied to heavy trucks, including an equalizing beam, an axle, a vehicle frame, and an air spring assembly 1, and the overall opening of the equalizing beam is upward. C-shaped, the middle part of the equalizing beam is connected to the axle, and an air spring assembly 1 is respectively arranged on the upper side of both ends of the equalizing beam. The air spring assembly 1 is connected to the vehicle axle through the equalizing beam, and the equalizing beam is connected to the vehicle axle through U-shaped bolts. The air spring assembly 1 includes an airbag and an airbag bracket, and the equalizing beam is connected to the vehicle frame through the airbag bracket. The air suspension system also includes a straight thrust rod assembly 4, a longitudinal thrust rod assembly, a V-shaped thrust rod assembly 3, a rear shock absorber assembly 2, a rear stabilizer...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com