Waterway shunting device for pipeline and using method

A diversion device and pipeline technology, which is applied in the direction of water supply equipment, cleaning sewer pipes, sewer pipe systems, etc., can solve the problems of inconvenient use, time-consuming and laborious, inconvenient disassembly and assembly of pipeline flushing equipment, etc., to save water resources and avoid excessive use Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

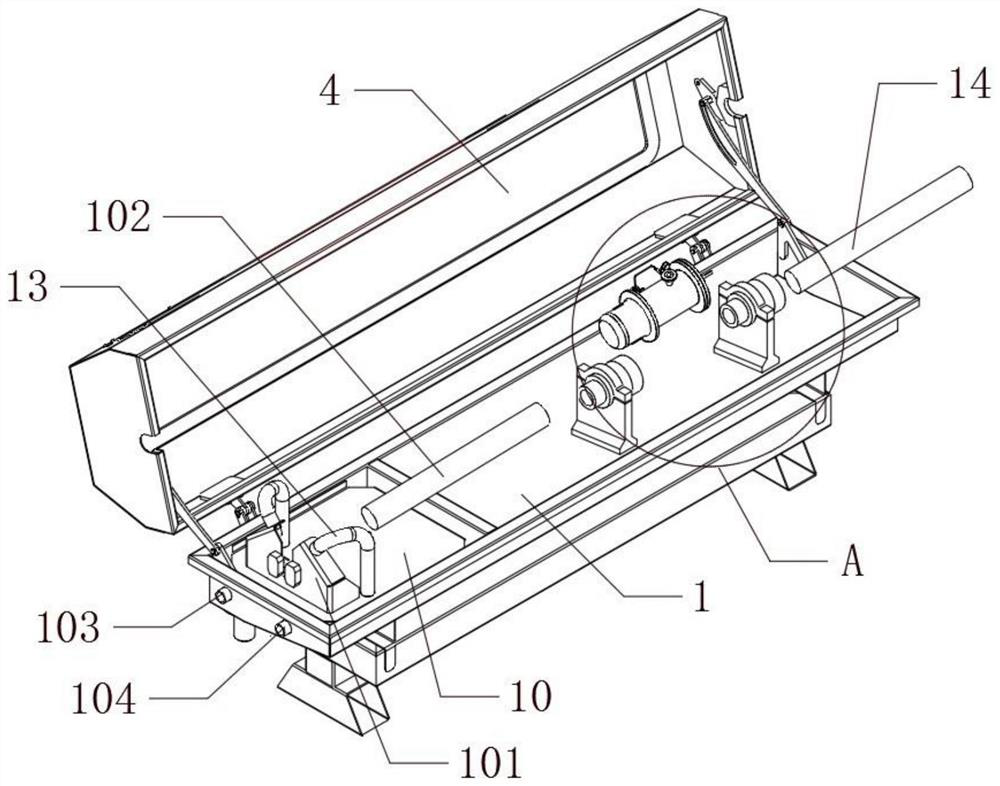

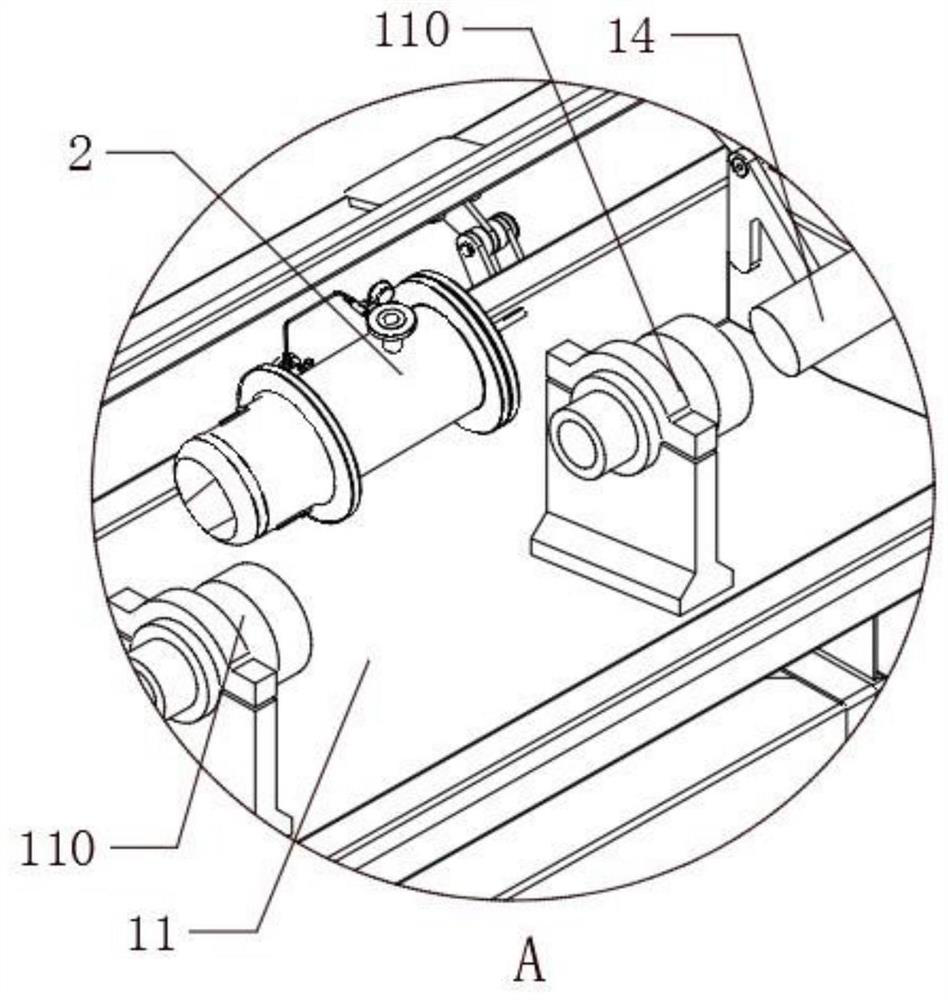

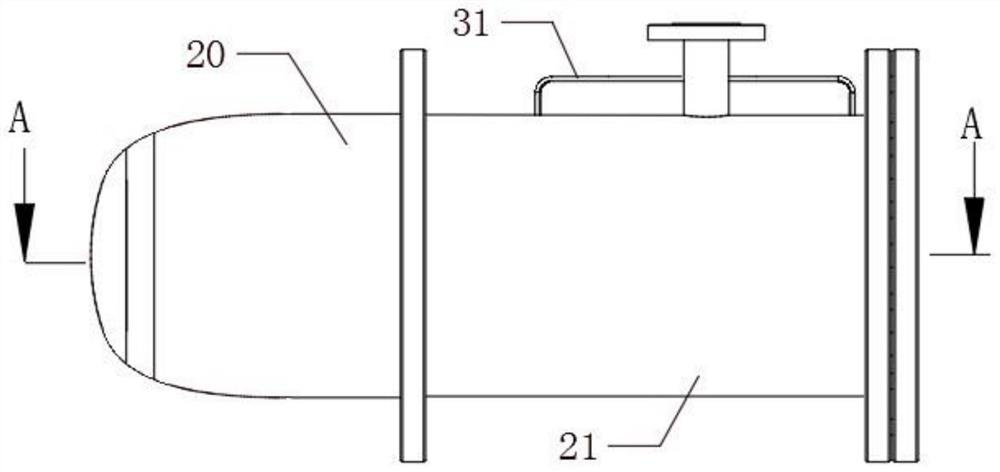

[0041] Such as Figure 1-7 As shown, a water diversion device for pipelines of the present invention includes an operation console 1, a liquid inlet area 10 arranged on the upper end of the operation console 1, and a pipeline joint area 11. The liquid inlet area 10 has a liquid inlet junction 101, Connect the hose 102, the connecting hose 102 cooperates with the liquid inlet joint 101 to connect the liquid inlet area 10 with the pipeline joint area 11, and the side of the pipeline joint area 11 away from the liquid inlet area 10 is connected to the pipeline 14 to be flushed, and the inlet The liquid area 10 and the pipe joint area 11 are designed to be divided into multiple sections for the multiple pipes to be flushed by the pipe 14 to be flushed, which is more convenient to use.

[0042] The outside of the console 1 is provided with a first liquid inlet 103 and a second liquid inlet 104. Two liquid inlet pipes 13 are connected to the liquid inlet joint 101. The first liquid ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com