Pneumatic vertical rotating suction machine and utility unit thereof

A technology of vertical rotation and suction cup machine, which is applied in the direction of load hanging components, transportation and packaging, etc. It can solve the problems of high risk factor, long vacuum time consumption, inconvenient shaking control, etc., and achieve high efficiency, damage protection, and increased safety. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

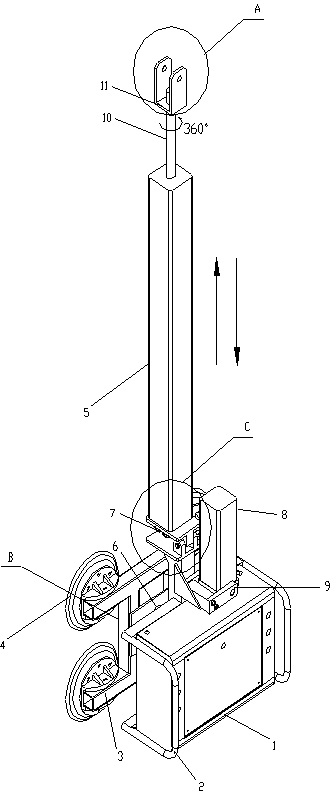

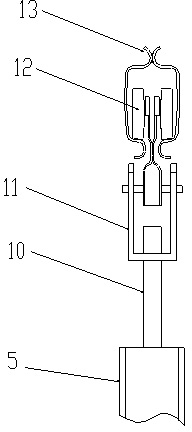

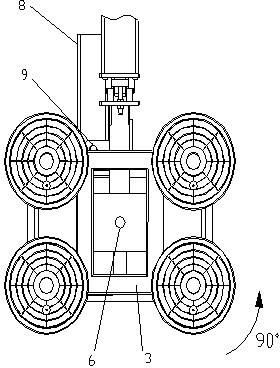

[0044] A pneumatic vertical rotary suction cup machine, which is composed of two sets of parts, one is the suspension part: column type or wall type cantilever crane (the fixed cantilever method is selected according to the characteristics of different sites of customers), the sliding trolley is suspended and slid in the Ω track; the other is Pneumatic vacuum suction cup machine, using the telescopic function of two cylinders and the mechanical cooperation of the mechanical shaft to realize the lifting and vertical rotation of the machine, using the high-efficiency and stable characteristics of the vacuum generator, the vacuum pressure is controlled by the ventilation valve, one-way valve, and pneumatic control components. During the conversion of flow control, the machine generates vacuum pressure to absorb the sheet in an instant. The suction...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com