Compound, polymer comprising the same and chemically amplified resist composition comprising the polymer

A polymer, a representative technology, applied in the fields of organic chemistry, optics, patterned photoplate process, etc., can solve problems such as unsatisfactory research results and decreased photosensitive speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

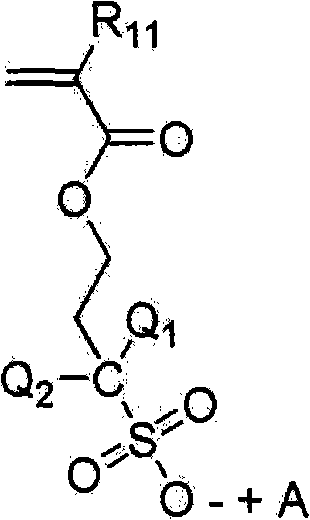

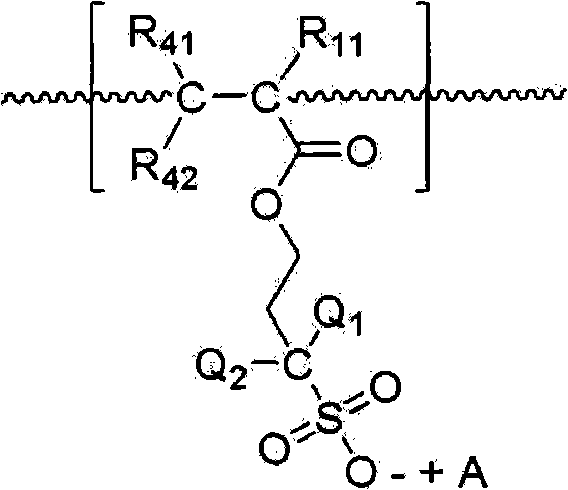

Method used

Image

Examples

Synthetic example

[0185] 1) Synthesis of sodium salt of difluorohydroxypropane sulfonate

[0186] In an ice bath, 83 g of ethyl 3,3-difluoro-3-sulfopropionate sodium salt was dissolved in 160 mL of methanol and 1.2 L of tetrahydrofuran (THF), and 44 g of sodium borohydride was slowly added dropwise to the solution . After the dropwise addition was complete, the reaction mixture was taken out from the ice bath and heated to 60°C. The reaction mixture was stirred at this temperature for about 4 hours.

[0187] The reaction mixture thus stirred was quenched with distilled water, and then the solvent was removed. The reaction mixture obtained after removing the solvent was redissolved in distilled water, and the obtained solution was acidified to pH 5-6 with concentrated hydrochloric acid.

[0188] The acidified reaction mixture was concentrated again, and methanol was added thereto to obtain a slurry. The slurry was filtered to remove inorganic salts, and the filtrate was washed twice with hex...

Embodiment 1

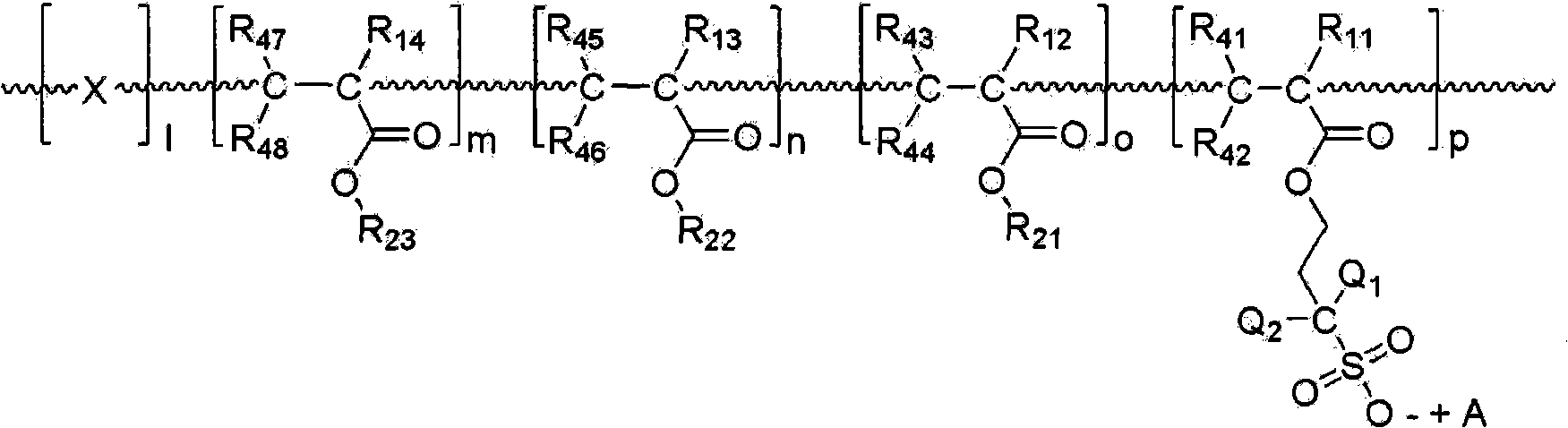

[0210]As polymerized monomers, 13 g of 2-methyl-2-adamantyl acrylate, 8.4 g of γ-butyrolactone methacrylate, 11.6 g of 3-hydroxy-1-adamantyl methacrylate and 1 g 2-Methacrylic acid-2,2-difluoro-2-sulfopropyl ester diphenyltolylsulfonium salt represented by the formula [D] in the above Reaction Scheme 3 was dissolved in 58 g of 1,2-dichloroethane In order to prepare the monomer mixture.

[0211] A reaction bath was obtained by adding 3.7 g of norbornene, 2.5 g of azobisisobutyronitrile (AIBN) as a polymerization initiator, and 117 g of 1,2-dichloroethane as a polymerization solvent into a 250-mL flask, And nitrogen gas was introduced into the reaction bath. The mixture was stirred for 1 hour while maintaining the temperature at 15°C to 25°C.

[0212] While keeping the temperature of the reaction bath at 65° C., slowly drop the above monomer mixture into the reaction bath within 1 hour to prepare a reaction mixture, and allow the reaction mixture to react for 16 hours. After ...

Embodiment 2

[0217] Polymers were prepared in the same manner as in Example 1 except that the values of l, m, n, o and p in formula (11) were changed by adjusting the amount of each monomer used for polymerization. The l, m, n, o, and p values of the polymer in formula (11) of Example 2 were 0.24 for l, 0.25 for m, 0.30 for n, 0.18 for o, and 0.03 for p.

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com