Frication hinge

A friction hinge, hinged technology, used in door/window fittings, folding panels, buildings, etc., can solve problems such as opening dead spots

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

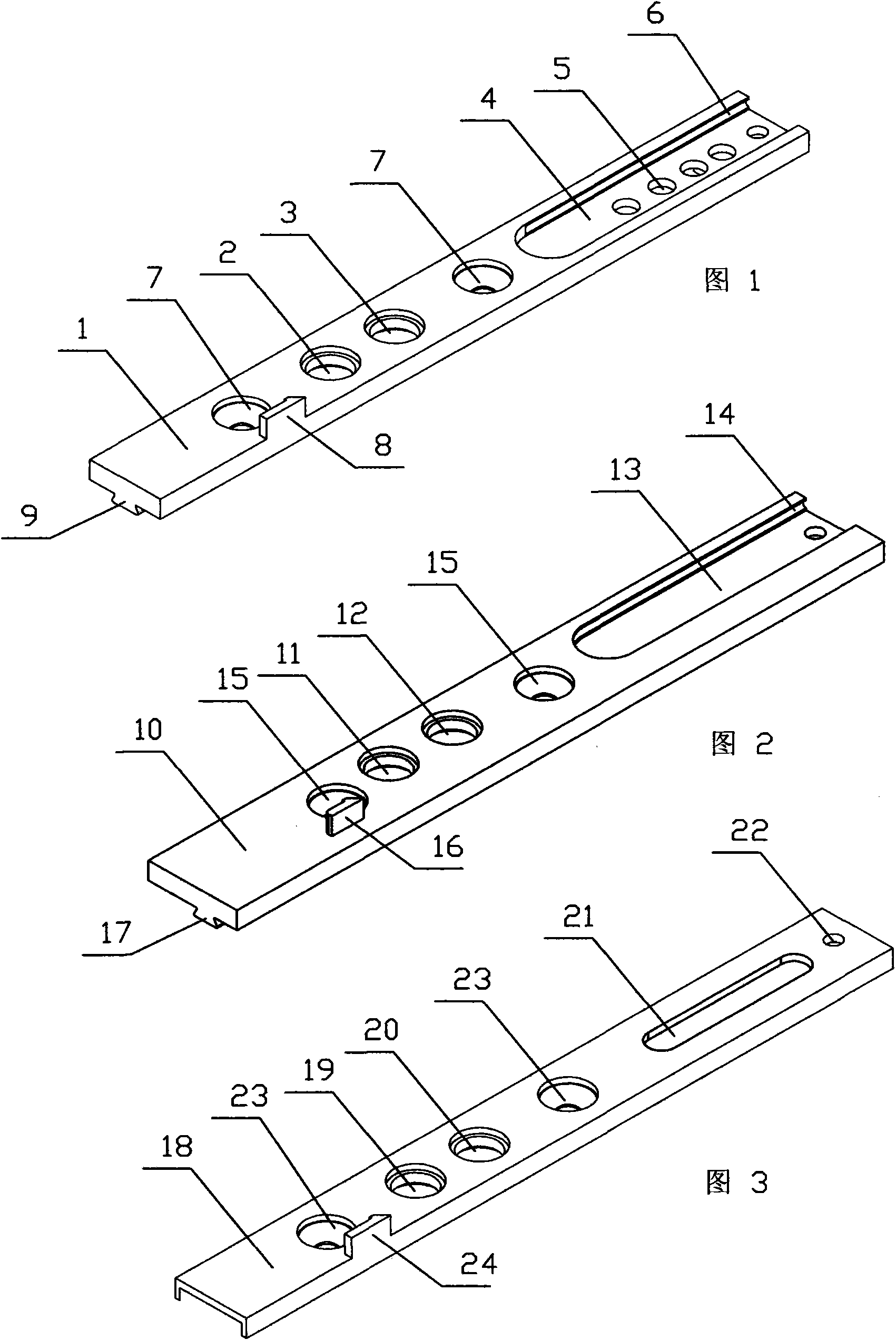

[0045] The three-dimensional structure diagram of a friction hinge hole positioning slider frame connecting plate is as follows figure 1 As shown, wherein: 1 is the friction hinge hole positioning frame fixing plate, 2 is the hinge hole of the support plate, 3 is the hinge hole of the middle support plate, 4 is the strip groove of the frame fixing plate, and 5 is the positioning hole of the strip groove of the frame fixing plate, The 6th, the frame fixing plate bar-shaped guide groove, the 7th, the frame fixing plate fixing hole, the 8th, the opening spring fixing plate, and the 9th, the dovetail tenon.

Embodiment 2

[0047] The three-dimensional structure diagram of a friction hinge limit wrench slider frame connecting plate is as follows figure 2 As shown, wherein: 10 is the friction hinge frame connecting plate, 11 is the hinge hole of the support plate, 12 is the hinge hole of the middle support plate, 13 is the strip-shaped groove of the frame fixing plate, 14 is the strip-shaped guide groove of the frame fixing plate, and 15 is the frame Fixed plate fixing hole, 16 is to open spring fixed plate, and 17 is dovetail tenons.

Embodiment 3

[0049] The three-dimensional structure diagram of a friction hinge chute frame fixing plate is as follows image 3 As shown, among them: 18 is the friction hinge chute frame fixing plate, 19 is the hinge hole of the support plate, 20 is the hinge hole of the middle support plate, 21 is the strip-shaped chute of the frame fixing plate, and 22 is the end of the strip-shaped chute of the frame fixing plate Fixed hole, 23 is frame fixed plate fixed hole, and 24 is to open spring fixed plate.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com