Leakage blocking device for leaking oil well

A technology for oil wells and oil leakage, which is applied in the field of plugging devices for oil leaking oil wells. It can solve the problems of poor plugging effect and rapid plugging of non-leakage positions, so as to achieve good plugging effect and avoid huge pollution.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

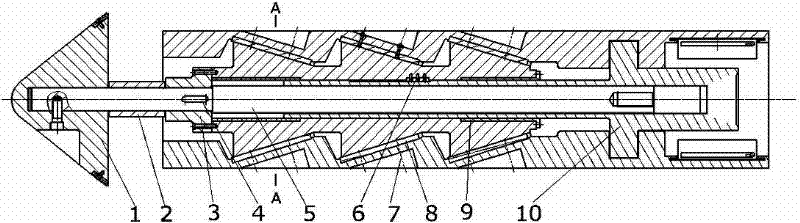

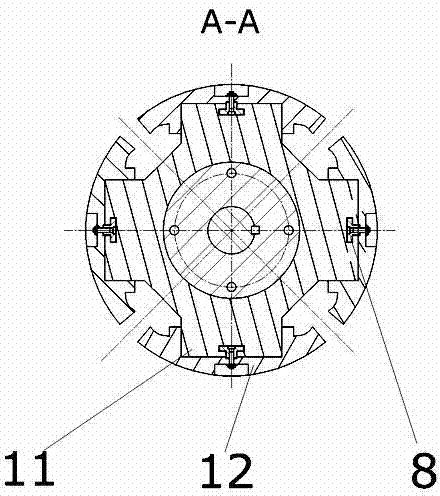

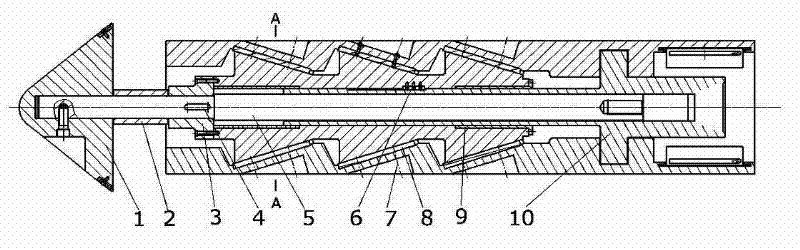

[0018] like figure 1 As shown, the plugging device for oil spilled oil wells of the present invention includes a casing 10, and an expansion cone 11 that can slide axially along the casing is set on the left end of the casing 10, and the outer peripheral surface of the expansion cone 11 is evenly provided with a A group of axially inclined wedge-shaped surfaces, the expansion cone 11 is provided with a group of axially arranged and radially expandable sector blocks 12, such as figure 2 As shown, the sector block 12 has a wedge-shaped inner surface that fits with the wedge-shaped surface of the expansion cone 11, and the two matching wedge-shaped surfaces are connected to the chute through the axially arranged slider 8, and the chute can be a T-shaped chute, the T-shaped chute can be arranged axially on the wedge-shaped surface along the expansion cone, the slider is an independent slider that can be matched with the T-shaped chute, the slider 8 is connected to the sector thro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com