A non-foaming fast-curing high-strength polyurethane plugging and waterproof grouting material

A grouting material and polyurethane technology, applied in the field of building materials, can solve the problems of inability to achieve long-term waterproofing and reinforcement of concrete, and achieve the effects of good sealing and waterproofing effect, good stability and high mechanical strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] Component A:

[0028] Add tetrahydrofuran diol, tetrahydrofuran copolyether diol and hydroxyl-terminated polybutadiene into the reaction kettle according to the mass ratio of 0.5:3:0.2, heat to (115±5)°C while stirring, vacuum dehydrate for 3 hours, cool down and store for mixing Diol oligomers: Add the isocyanate monomer IPDI into the reaction kettle, heat to (80±5)°C, slowly add the dehydrated mixed diol oligomers dropwise, after 1.5h, mix the diols to low The uniform dropwise addition of the polymer is completed, and when the isocyanate group content of the prepolymer reaches 20%, the reaction is stopped, and the temperature of the prepolymer is lowered to below 50° C. for storage. Add 15 parts of prepolymer, 30 parts of PAPI, 25 parts of vegetable oil-based plasticizer and 30 parts of citric acid ester plasticizer into the reaction kettle, stir and defoam under vacuum for 1 hour, and discharge to obtain component A.

[0029] Component B:

[0030] Add 10 parts of t...

Embodiment 2

[0033] Component A:

[0034] Add tetrahydrofuran diol, tetrahydrofuran copolyether diol and hydroxyl-terminated polybutadiene into the reaction kettle according to the mass ratio of 1:3:0.5, heat to (115±5)°C while stirring, vacuum dehydrate for 3 hours, cool down and store for mixing Diol oligomers: Add the isocyanate monomer IPDI into the reaction kettle, heat to (80±5)°C, slowly add the dehydrated mixed diol oligomers dropwise, after 1.5h, mix the diols to low After the uniform dropwise addition of the polymer is completed, the reaction is stopped when the isocyanate group content of the prepolymer is 15%, and the temperature of the prepolymer is lowered to below 50° C. for storage. Add 5 parts of prepolymer, 60 parts of carbodiimide-modified MDI and 30 parts of fatty acid ester plasticizer into the reaction kettle, stir and defoam under vacuum for 1 hour, and discharge to obtain component A.

[0035] Component B:

[0036] Add 23 parts of tetrafunctional polypropylene oxi...

Embodiment 3

[0039] Component A:

[0040] Add tetrahydrofuran diol, tetrahydrofuran copolyether diol and hydroxyl-terminated polybutadiene into the reaction kettle according to the mass ratio of 0.75:3:0.35, heat to (115±5)°C while stirring, vacuum dehydrate for 3 hours, cool down and store for mixing Diol oligomers: Add the isocyanate monomer IPDI into the reaction kettle, heat to (80±5)°C, slowly add the dehydrated mixed diol oligomers dropwise, after 1.5h, mix the diols to low After the uniform dropwise addition of the polymer is completed, the reaction is stopped when the isocyanate group content of the prepolymer is 17.5%, and the temperature of the prepolymer is lowered to below 50° C. for storage. Add 10 parts of prepolymer, 45 parts of MDI-50, 22.5 parts of vegetable oil-based plasticizer and 20 parts of fatty acid ester plasticizer into the reaction kettle, stir and defoam under vacuum for 1 hour, and discharge to obtain component A.

[0041] Component B:

[0042] Add 16 parts o...

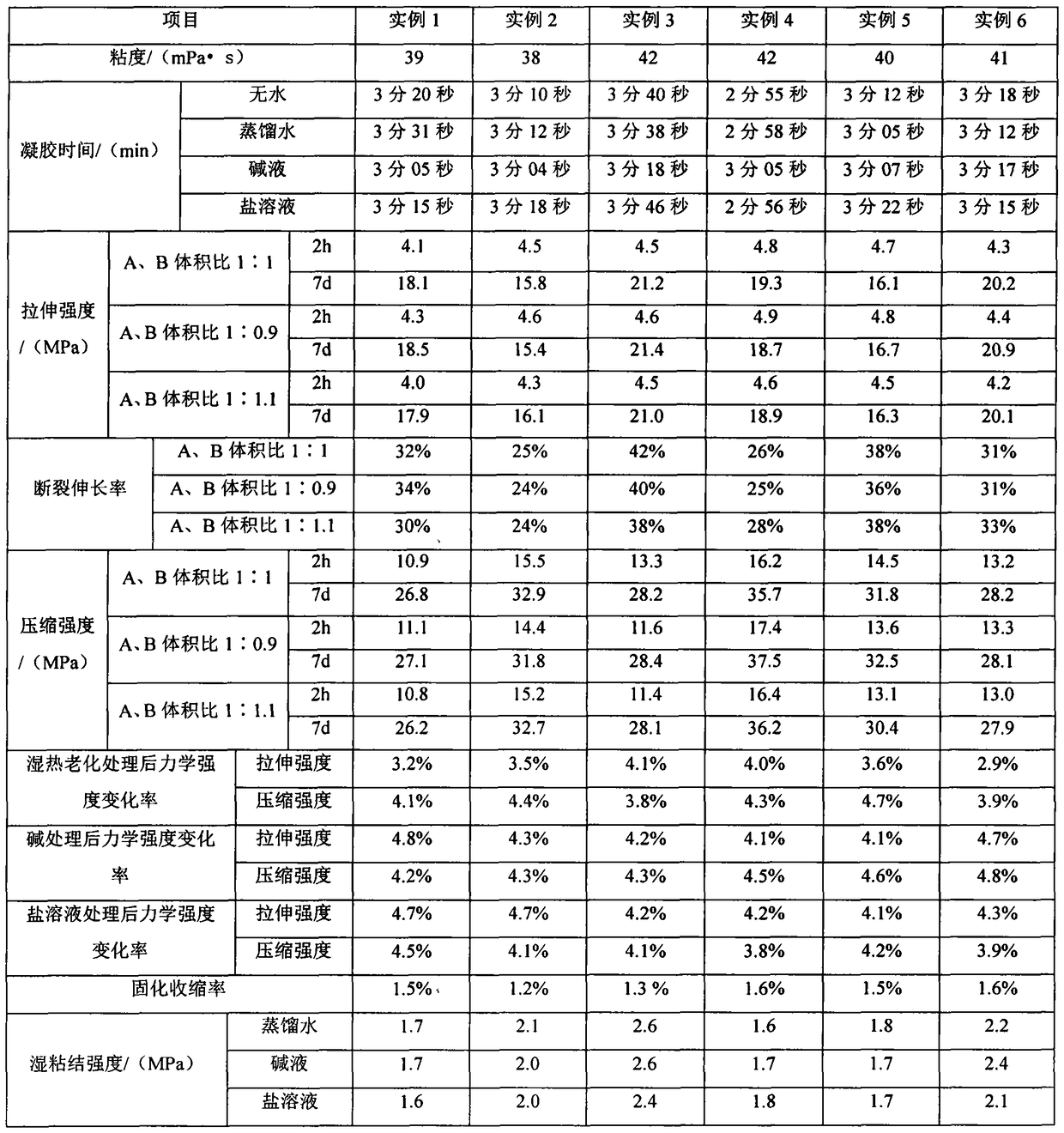

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com